Move palletized products where your crew actually needs them – fast, clean, and with less handling.

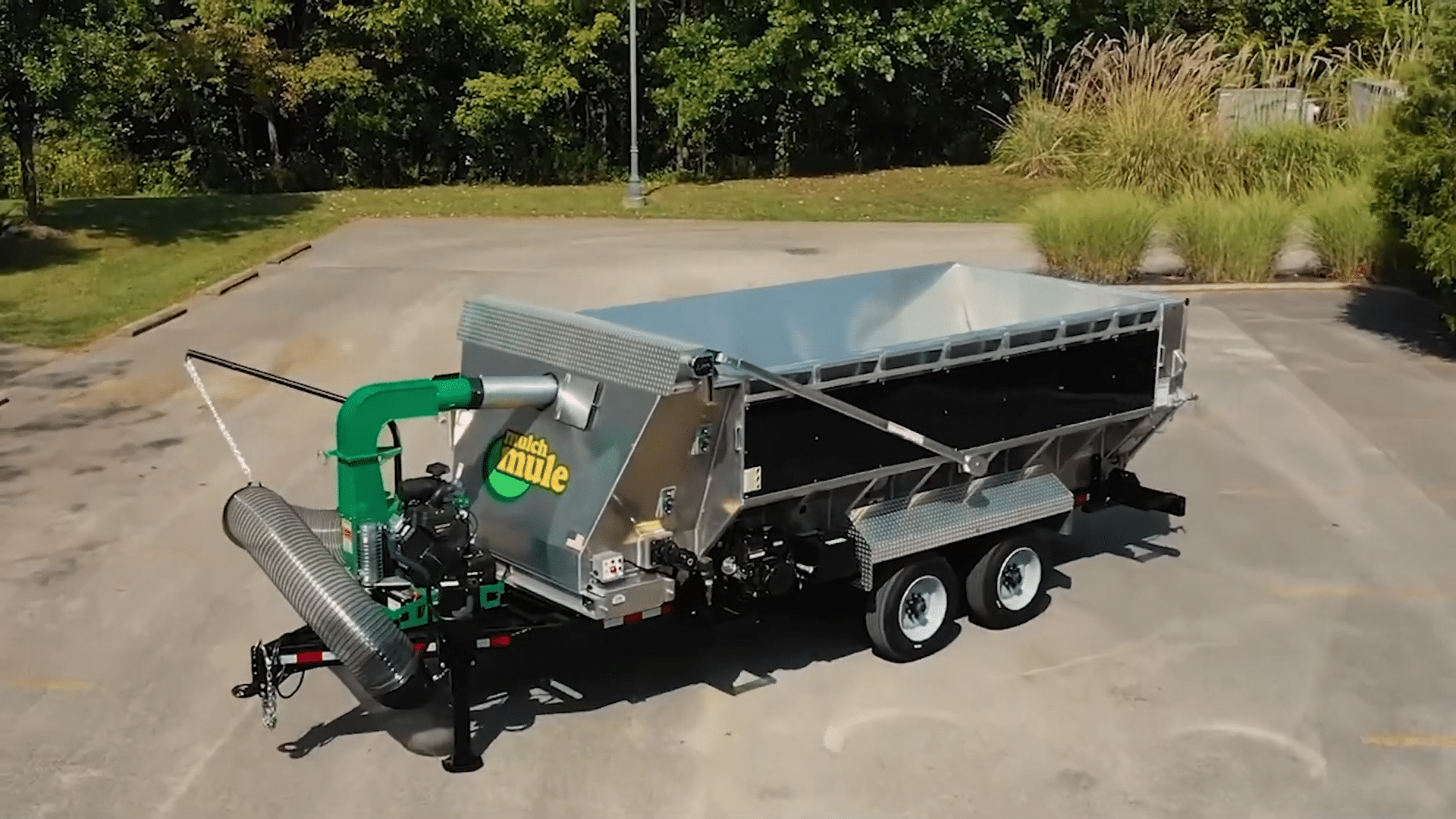

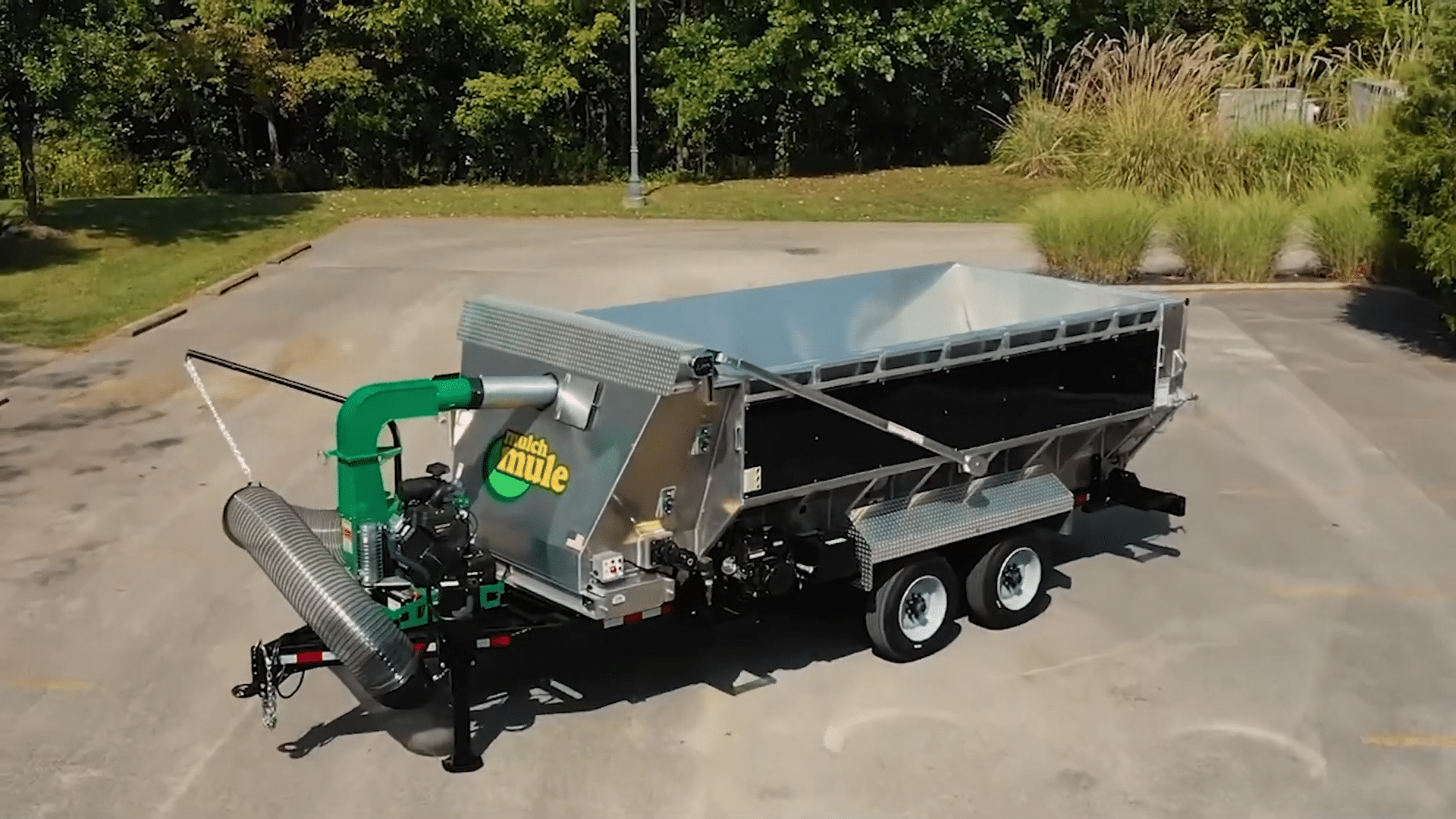

Mulch Mule isn’t just for bulk material. It’s also a practical way to load, transport, and unload palletized loads around job sites – so you can reduce bottlenecks, cut down on back-and-forth trips, and keep installs moving.

If these headaches sound familiar, you’re not alone.

Mulch Mule’s reversible live-floor conveyor lets you move pallets forward or in reverse to position them at the unloading point—so off-loading is faster, safer, and more controlled than a dump trailer.

Mulch Mule’s reversible live-floor conveyor lets you position pallets forward or reverse for quicker, safer loading and off-loading—without the extra dragging and re-handling a dump trailer often requires.

Use the reversible live-floor to convey pallets to the unloading point so you can lift off cleanly—without chaining and dragging pallets to the rear first.

Reduce risky, awkward moves like pulling pallets by chain. The live-floor helps position loads with controlled forward/reverse movement instead of brute force.

Fewer grabs and adjustments means less pallet breakage, less shifting, and fewer damaged goods during unloading.

Move pallets when you need to—then switch back to bulk material handling as jobs change across seasons.

Transport palletized stone and large slab materials as a secured load so crews can stage near install zones.

Stage pallets of product closer to lift points to reduce “drop zone pile-ups” and manual shuttling.

Move palletized boxed goods and supplies efficiently across yards, campuses, and industrial sites.

Reduce time wasted repositioning palletized materials after delivery—especially when staging areas are limited.

The reversible live-floor conveyor lets you roll pallets forward to load and position them—then reverse the process to unload fast with fewer touches.

1

Load palletized materials onto the Mulch Mule deck using a forklift or other appropriate lifting equipment.

2

Use the live-floor to roll pallets forward to fit your next pallet/pallets and fine-tune spacing and positioning—without extra handling.

3

When it’s time to unload, reverse the live-floor to convey pallets precisely to the unloading point—so you can lift once instead of dragging pallets from the front to the rear.

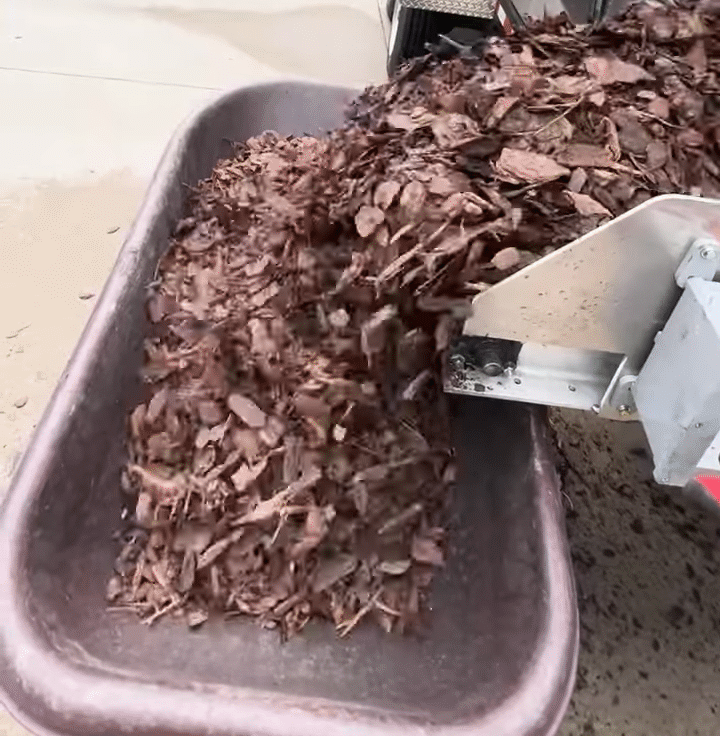

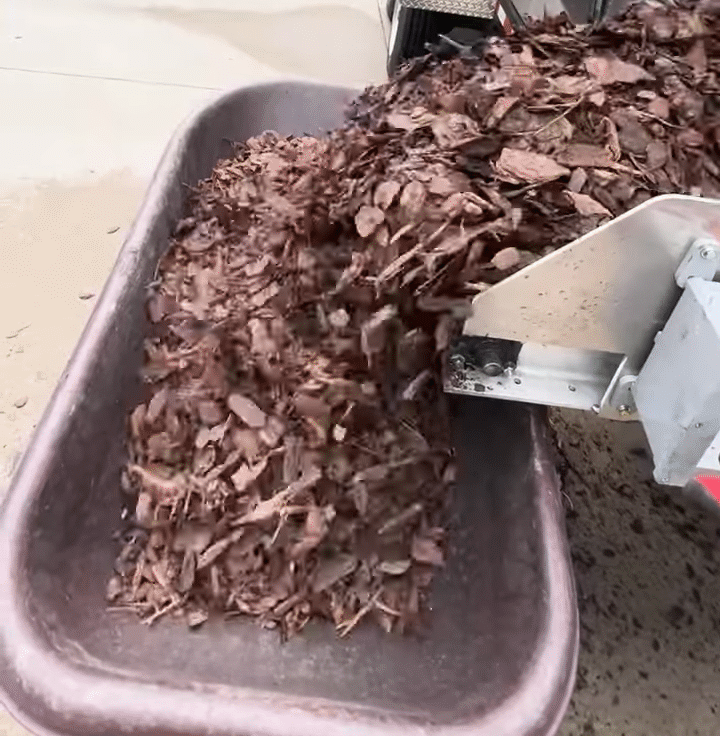

The Mulch Mule isn’t just for moving palletized materials. It’s engineered to handle a wide range of materials—mulch, gravel, soil, bark, leaves, compost, sand, and more—making it the ultimate all-in-one solution for landscaping and material distribution.

“We’re seeing double the productivity with the same amount of guys… and the morale has been phenomenal this spring compared to prior years.”

Minard’s Landscape and Design

“We bought a mulch mule… we have two of them now that have been very helpful for us, really speed up the productivity for us. With the labor industry and how bad the shortages are it’s really helped us out in a lot of beneficial ways.”

Watch the Mulch Mule in action and see how it can transform your landscape business. Check out our YouTube videos for real-world performance and customer success stories.

A job well done starts with the best equipment. Contact us today for more information on Mulch Mule and how it can enhance your palletized material transportation.