Landscaping professionals navigate a highly competitive and demanding environment. On a daily basis, businesses grapple with a complex web of challenges: coordinating crews on time-sensitive projects, adapting to ever-rising customer expectations, and managing the constant pressures of a skilled labor shortage.

These operational hurdles are compounded by financial pressures like spikes in material expenses and rising insurance premiums. If left unaddressed, these issues can quickly erode profitability, drain employee motivation, and undermine the trust you’ve worked hard to build with your clients.

Effectively overcoming these obstacles requires moving beyond traditional methods and embracing a more strategic, forward-thinking approach. The solution lies in carefully evaluating your current operations and integrating modern tools and strategies. Are you relying too heavily on manual tasks that cause burnout? Could your budgeting be more precise to prevent runaway costs? This article is designed to guide you through that evaluation. We will explore the ten most pressing landscaping business management challenges in the industry and provide practical, actionable solutions—from adopting automation to revising staffing approaches—that will help you create a more manageable, resilient, and profitable workflow.

1. Addressing Labor Shortages

Many landscaping firms find it hard to recruit and retain skilled labor. High turnover rates, physically demanding work, and seasonal fluctuations create a tight labor market that can hinder project timelines. These shortages force some businesses to refuse new opportunities, limiting revenue growth.

Strengthening your recruiting and retention efforts:

- Offer ongoing development programs and incentives to show employees they have a future with your company.

- Reduce strenuous manual tasks by deploying equipment that automates repetitive processes, thereby minimizing the risk of injuries and burnout.

- Develop a robust staffing plan that accounts for peak seasons, ensuring you have enough skilled hands when demand surges.

Fostering a culture of mentorship, where seasoned employees guide newcomers, can boost morale and promote skill development. Investing in modern material-handling equipment can further reduce the physical strain on your crews, freeing up resources to focus on strategic areas like landscape design or client relations.

2. Combatting Rising Operational Costs

Elevated operational costs—including labor, fuel, and equipment expenses—pose ongoing threats to profit margins. Material inefficiencies, in particular, can become a hidden drain, inflating your budgets and impacting project bids. When the goal is to deliver high-quality results without breaking the bank, you need to identify and eliminate cost leaks early.

Practical steps to reduce expenses:

- Use strategic automation to lower labor costs and speed up routine chores.

- Employ standard operating procedures and efficient processes for tasks like procurement, storage, and transport.

- Explore ways to cut costs around material acquisition and distribution, ensuring you don’t over-purchase or discard excessive quantities.

Investing in durable, easy-to-maintain equipment can yield long-term savings. For example, consider the benefits of programs that offer parts and comprehensive warranties to minimize breakdowns. Keeping equipment in prime condition not only preserves your bottom line but also ensures that your crew can operate safely and efficiently.

3. Overcoming Delays and Improving Productivity

Delayed projects derail revenue projections, create scheduling conflicts, and frustrate clients. Time is money in landscaping, and any inefficiency multiplies your operational costs. Often, outdated machinery and labor-intensive workflows hamper your ability to complete tasks on schedule.

How to streamline and accelerate projects:

- Centralize communication to keep teams aligned on daily objectives and potential bottlenecks.

- Incorporate automated systems that simplify tasks such as loading and material distribution to relieve some manual workload.

- Standardize quality checks and encourage proactive troubleshooting to prevent minor issues from escalating into major delays.

Advanced equipment demonstrations can showcase how automation can contribute to smoother operations, allowing crews more time for specialized tasks like detailed landscape design or plant health assessments.

4. Elevating Workplace Safety and Team Morale

Landscaping is a physically demanding field, exposing employees to potential hazards and repetitive strain injuries. Injuries not only remove valuable team members from the workforce but also increase workers’ compensation premiums, disrupt schedules, and reduce overall morale.

Promote a safer, more engaged work environment by:

- Providing comprehensive training in equipment usage and hazard recognition.

- Reducing heavy lifting through machinery and automated features designed to ease physical strain.

- Continually reviewing and refining safety protocols, aiming for minimal workplace incidents.

Leaders in landscaping are increasingly focusing on ergonomics, ensuring that staff use equipment in ways that minimize injury risk. Mechanizing labor-intensive operations not only protects workers but also contributes significantly to building a committed, productive team.

5. Scaling Up without Sacrificing Quality

As your business grows to handle larger contracts and expand across new regions, maintaining consistent quality across projects becomes a challenge. Overexpansion without proper systems may lead to disorganized project management, ultimately affecting client satisfaction and tarnishing your reputation.

Key tips for sustainable expansion include:

- Embracing scalable technology that supports process improvements regardless of business size.

- Standardizing best practices to ensure quality is uniform across all teams and locations.

- Focusing on building systems that support growth without overextending your resources.

Embracing automated solutions in areas such as mulching and material handling can streamline processes and contribute to smoother operations. While specific percentages may vary by business, many companies find that integrating advanced equipment helps position them for steady, scalable growth.

6. Smooth and Accurate Material Management

Mismanaged inventory can lead to shortages, overstock, or inefficiencies that affect project timelines and inflate budgets. Whether you’re handling mulch, soil, or decorative stone, effective material management is essential to keeping projects on track.

Enhance material handling by:

- Using data-driven forecasting methods to accurately predict material needs.

- Streamlining bulk loading and delivery processes to reduce manual touchpoints.

- Keeping detailed records to ensure precise purchasing and transportation of materials.

Adopting structured inventory oversight can save both time and money, ensuring that crews have exactly what they need for each project, when they need it.

7. Tackling Seasonal Fluctuations

The landscaping business is inherently seasonal. Spring brings a surge in planting activities, while autumn demands intensive leaf collection and maintenance. Balancing labor and resources through these cycles can be a constant challenge.

Adaptive measures for seasonal agility include:

- Cross-training employees to handle diverse roles according to seasonal demands.

- Keeping equipment versatile to perform multiple tasks across various seasons.

- Scheduling preventative maintenance during transitional periods to ensure all equipment is reliable for peak times.

Diversifying services—for instance, adding seasonal storm cleanup—can also help maintain revenue during traditionally slow periods.

8. Sustaining Profitability in a Tight Market

Profitability remains paramount even as you optimize processes and streamline workflows. External factors such as fuel price volatility, labor costs, and changing market conditions continuously pressure your margins. Every edge matters when competition is fierce.

Maintain healthy margins with strategies like:

- Implementing strict cost controls and budget oversight across all projects.

- Routinely reviewing operational overhead and adjusting processes to maintain target profitability margins.

- Leveraging automation and updated equipment to complete more projects with minimal delays.

The adoption of automated solutions and modern process improvements can free up valuable operational time, allowing your business to remain competitive in challenging economic conditions.

9. Meeting and Exceeding Client Expectations

In today’s instant-gratification world, clients demand fast, transparent, and high-quality service. Failing to meet these expectations can result in negative reviews and lost business opportunities. Delivering consistent results is essential for brand recognition and long-term loyalty.

Suggestions for ensuring top-tier customer satisfaction include:

- Clearly communicating project timelines and providing regular updates.

- Leveraging precision machinery to enhance accuracy and reduce delays in final project stages.

- Being flexible enough to adapt designs or schedules based on evolving client needs.

Some accounts suggest that using faster, more precise equipment can improve repeat service rates, contributing to a stronger reputation and increased referrals—even if specific case studies are not universally documented.

10. Integrating Sustainability and Environmental Responsibility

The landscaping industry is unique in its direct interaction with the environment. As a result, adopting sustainable practices is not only preferred but increasingly required. Eco-friendly initiatives can reduce waste, lower costs, and enhance your company’s reputation.

Practical steps toward sustainability include:

- Choosing equipment that performs tasks efficiently while consuming less energy.

- Implementing precise application methods to minimize material waste.

- Aligning with sustainable landscaping practices that appeal to environmentally conscious customers.

Integrating sustainable methods with technological advancements creates an opportunity for organizations to achieve both economic and ecological benefits, fostering long-term success and consumer trust.

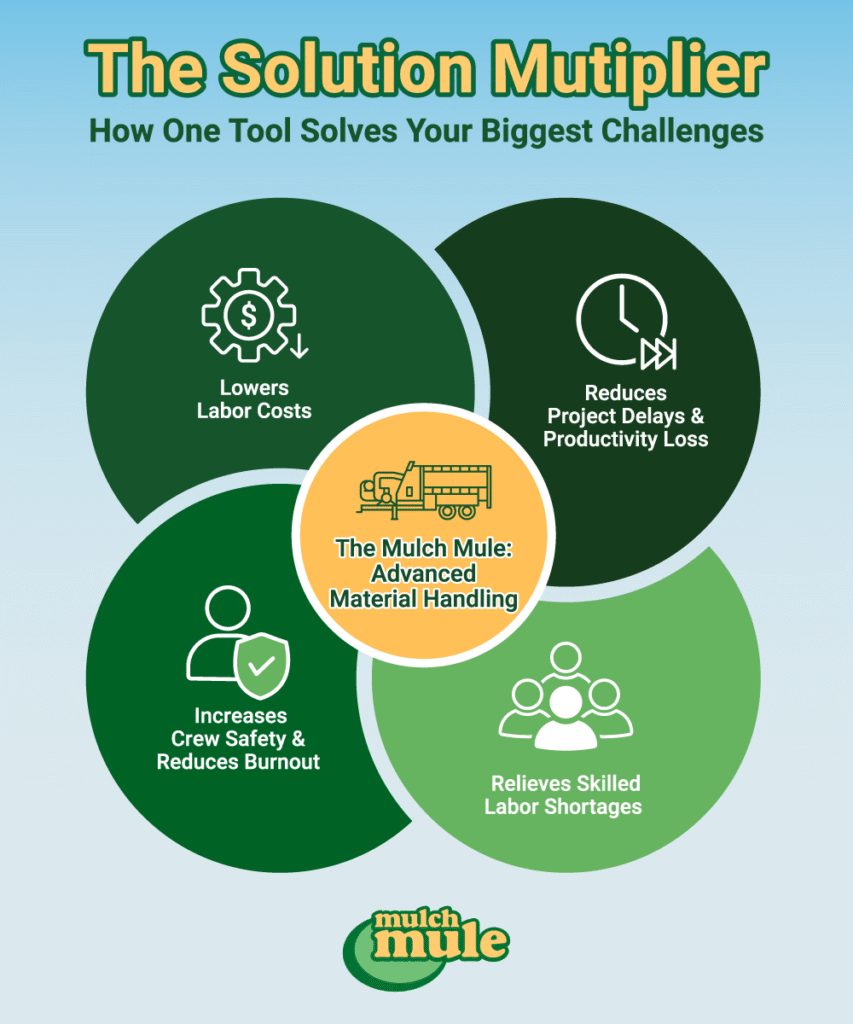

The Solution Multiplier: How the Mulch Mule Solves Key Challenges

After outlining the top challenges in landscaping, it becomes clear that the most effective solutions are the ones that tackle multiple problems at once. A strategic investment in the right equipment doesn’t just solve one issue—it creates a positive ripple effect across your entire operation. This is where the Mulch Mule comes in.

The Mulch Mule is an advanced material-handling trailer engineered specifically to address the core challenges of modern landscaping:

- Combats Labor Shortages and Safety Risks: By automating the most physically demanding parts of material handling with its live floor system, the Mulch Mule reduces the need for manual shoveling. This makes the job safer, drastically cutting down on back injuries, and allows you to run more efficient crews, making your business less vulnerable to labor shortages.

- Destroys Delays and Boosts Productivity: The Mulch Mule can unload 15 cubic yards of material in minutes and fill a wheelbarrow in under six seconds. This game-changing speed eliminates bottlenecks, keeps projects on schedule, and allows your teams to complete more jobs without sacrificing quality.

- Lowers Operational Costs and Sustains Profitability: By saving thousands of dollars in labor costs and minimizing injury-related expenses, the Mulch Mule directly boosts your bottom line. Faster project completion means higher revenue capacity, ensuring you remain profitable even in a tight market.

- Adapts to Seasonal Fluctuations: This isn’t just a single-season tool. With attachments like a vacuum debris loader for fall cleanup or the ability to handle sand in the winter, the Mulch Mule is a versatile, year-round asset that ensures a consistent return on your investment.

Future-Proofing Your Landscaping Business Through Strategic Innovation

Thriving in the landscaping business requires confronting operational challenges head-on. As we’ve seen, issues like labor shortages, rising costs, and project delays can limit your growth. The solution isn’t to work harder—it’s to work smarter.

By integrating innovative landscaping technology like the Mulch Mule, you can transform your operations from the ground up. Automating material handling is a strategic move that enhances safety, skyrockets efficiency, and directly boosts your profitability. It’s time to stop letting these challenges manage you and start building a more resilient, scalable, and successful business.

Ready to see how much time and money you could save? Get a Quote for the Mulch Mule today and take the first step toward a more efficient and profitable future.