Have you ever wondered how a single shipping delay can derail a critical landscaping project? In the years to come, the challenges in supply chain management are set to intensify, impacting everything from material procurement to labor management. This article details the urgent supply chain challenges facing landscaping businesses and offers practical, actionable strategies to overcome them. By exploring innovative solutions and streamlined processes, you’ll learn how to maintain efficiency and resilience even when disruptions threaten your operations.

Understanding the Role of Supply Chains in Landscaping

Supply chains are the backbone of the landscaping industry. They coordinate the timely delivery of key materials—soil, mulch, stone, rock, and lumber—and ensure that labor and equipment align with project schedules. A minor disruption in any of these areas can trigger delays, increase costs, and jeopardize project timelines. In an industry where time and client satisfaction are paramount, having a robust supply chain is critical for maintaining profitability and reputation.

Escalating demand and higher customer expectations mean that any inefficiencies in supply chain management can lead to significant setbacks. Landscaping companies must therefore adopt strategies that mitigate risks, optimize operations, and secure a competitive edge in an increasingly dynamic market. The smooth functioning of supply chains directly affects project planning, budget management, and the overall quality of deliverables.

Moreover, the landscaping sector is uniquely positioned because it often relies on a diverse set of materials, sometimes sourced from multiple regions. This interdependence means that poor coordination in one segment may have a domino effect on the entire project. With the growing influence of weather patterns and global disruptions, the need to continuously monitor supply conditions becomes increasingly important.

Key Supply Chain Challenges Facing the Landscaping Industry

Landscaping businesses will confront several interconnected challenges that could disrupt daily operations and overall profitability:

- Material Shortages:

- Essential materials such as mulch, soil, stone, and lumber are becoming scarce due to production limitations, unpredictable demand, and global disruptions.

- Fluctuating prices and limited availability force businesses to either absorb higher costs or risk project delays.

- In many cases, seasonal variations and natural disasters can further compound the scarcity, creating sudden shortages that are difficult to predict.

- Logistical Bottlenecks and Delivery Uncertainty:

- Shipping disruptions—including backlogged ports and driver shortages—complicate the transportation of bulk materials.

- Local roads and urban congestion can also slow down delivery times, adding to the unpredictability and challenging timely delivery.

- These bottlenecks may force companies to adjust their work schedules and deploy alternative distribution methods, which require additional planning and investment.

- Shrinking Workforce Availability:

- A decline in skilled labor coupled with the physically demanding nature of landscaping work places strain on staffing.

- Repetitive tasks increase the risk of injury and employee turnover, prompting businesses to seek automated solutions.

- Training new staff is both time-consuming and expensive, making it essential to protect existing employees by reducing physical strain.

- Increasing Demand for Year-round Services:

- Many clients, particularly in regions with continuous landscaping needs, are increasingly looking for services throughout all seasons. This trend can stretch supply chains and workforce capabilities as companies work to maintain adequate service levels year-round.

- Adapting to rapid weather changes while sustaining service quality across different seasons adds layers of operational complexity.

- Successfully managing these evolving expectations requires diversification of services and investment in versatile, multi-functional equipment that can adapt to varying environmental conditions.

- Rising Transportation and Fuel Costs:

- Increases in fuel prices and transportation expenses can quickly erode profit margins, particularly for businesses that rely on long-haul deliveries. For example, rising fuel costs alongside increasing transportation costs force companies to balance efficiency with timely delivery.

- Companies are compelled to invest in newer, more efficient vehicles and in route planning software to mitigate these expenses.

- Regulatory and Environmental Compliance:

- With growing pressure to reduce carbon footprints and adhere to stricter environmental regulations, landscaping companies must adjust their supply chain processes.

- Integrating eco-friendly practices, such as sourcing sustainable materials or using green energy for transportation, may require significant upfront investment and a reassessment of existing vendor relationships.

Broader Industry Impacts of Supply Chain Disruptions

Disruptions in the supply chain affect not only operational efficiency but also a company’s bottom line. When materials are delayed or prices surge unexpectedly, businesses may face:

- Missed deadlines and stalled projects, leading to dissatisfied clients.

- Increased financial pressures on small to mid-sized companies that lack the reserve funds to absorb extra costs.

- Strained partnerships with local suppliers, as inconsistent deliveries damage trust and reliability.

- Overall profit margin erosion, as businesses either absorb higher costs or pass them on to clients, risking competitiveness.

Such financial volatility can alter market dynamics significantly. Companies may find themselves forced to scale back on projects or delay the adoption of new technologies, undermining innovation. This uncertainty imposes long-term strategic challenges on both operational planning and investment decisions. Moreover, negative client experiences can lead to a tarnished reputation and decreased market share, further impacting a company’s long-term viability.

Strategies to Overcome Supply Chain Challenges

Effectively managing the supply chain in today’s unpredictable market requires a bold, flexible approach. Consider the following strategies:

1. Plan Proactively and Forecast Demand

Regularly analyze project forecasts and adjust plans to accommodate unexpected market changes. Keep an adaptable approach to fulfill client demands without compromising on quality or timelines.

- Analyze historical trends and seasonal demands to predict material needs.

- Use inventory management software for real-time tracking.

- Maintain relationships with backup suppliers and secure pre-negotiated supply agreements.

- Develop predictive models using past data to identify potential future shortages and prepare mitigation plans accordingly. Learn more about leveraging predictive models for better foresight.

2. Build Relationships with Local Suppliers

Maintain regular, transparent communication and consider formal agreements to ensure consistent material availability. Establishing long-term relationships builds trust and encourages collaboration in overcoming unforeseen challenges.

- Strengthen partnerships with regional suppliers, quarries, and nurseries.

- Leverage local sourcing to reduce transportation delays and support community economies.

- Work closely with local vendors to get alerts on any potential shifts in market availability or regional disruptions.

- Collaborate on local sustainability initiatives, ensuring that material sourcing aligns with eco-friendly practices.

3. Leverage Technology for Greater Visibility

Use modern inventory and scheduling tools to track supply levels, predict shortages, and streamline project management. Digital transformation not only improves efficiency but also provides actionable insights for proactive decision-making.

- Implement digital tools that monitor inventory levels, automate procurement, and track logistics.

- Use real-time data to adjust orders promptly and align material arrivals with labor schedules.

- Integrate cloud-based dashboards that consolidate data from various aspects of the supply chain for comprehensive oversight.

4. Diversify Material Choices

Selecting from diverse material sources can minimize supply chain disruptions and foster innovation. By exploring alternative options, businesses can ensure continued project flow while embracing cost-effective and sustainable practices.

- Identify alternative materials that can substitute for scarce resources without compromising quality.

- Evaluate the long-term prosperity of traditional materials versus innovative composites or synthetic alternatives.

- Encourage collaboration among suppliers and contractors to experiment with creative solutions that maintain aesthetic appeal while reducing dependency on limited resources.

- Engage in pilot projects to test alternative materials in controlled environments before wide-scale adoption.

5. Strengthen Internal Processes and Flexibility

Incorporate buffer periods into project timelines and be transparent with clients about realistic deadlines. Flexible scheduling ensures that delays in one aspect do not derail the entire project. Reserve funds for unexpected costs such as price surges and expedited shipping, ensuring stability during disruptions. Likewise, cross-training employees can enhance flexibility and reduce the impact of labor shortages.

- Build flexible project timelines that include buffer periods for unforeseen delays.

- Allocate contingency budgets for unexpected material cost surges or expedited shipping needs.

- Develop comprehensive risk management plans that include periodic reviews and updates to strategies.

- Train employees to adapt to new technologies and revised methodologies, ensuring that internal processes can quickly shift in response to external disruptions. Continue to invest in training programs and continuous learning to build a skilled, adaptable team.

- Establish a cross-functional team to continuously oversee and refine supply chain processes, ensuring that lessons learned from past disruptions are swiftly integrated into future planning.

Future Trends and Innovation Opportunities

While many challenges seem daunting, emerging trends provide opportunities for landscaping companies to transform their operations:

Embracing Digital Transformation

- The convergence of digital technology with supply chain management is steadily revolutionizing the way landscaping companies plan and operate.

- From blockchain for secure transaction tracking to AI-driven algorithms that optimize route planning and inventory management, digital tools offer unprecedented transparency and efficiency.

- Early adopters of these technologies not only mitigate risk but also gain a competitive edge in terms of customer service and operational flexibility.

Sustainability and Green Supply Chains

- As environmental concerns become paramount, sustainable practices within supply chains are no longer optional but required.

- Companies can gain market advantage by sourcing recycled or environmentally sustainable materials.

- Transitioning to energy-efficient logistics and transportation practices reduces carbon footprint and attracts eco-conscious clientele.

- Investments in renewable energy or electric vehicles for logistics not only align with corporate sustainability goals but also often lead to long-term cost savings.

Collaborative Ecosystems and Industry Partnerships

- The current market shift encourages broader collaboration among suppliers, manufacturers, and contractors.

- Creating industry-wide platforms for sharing best practices can lead to resource pooling and mutual benefits during disruptions.

- Such ecosystems can foster innovation, lead to shared risk, and create standardized procedures for crisis management.

Enhanced Workforce Training and Automation

- In response to labor shortages, investment in advanced training programs and automation is critical.

- Augmented reality (AR) and virtual reality (VR) training modules can quickly bring new employees up to speed with industry practices.

- Collaborative robots (cobots) that assist rather than replace human workers are on the rise, ensuring that technology supports employee safety and productivity without displacing the workforce entirely.

The Role of Equipment Innovations in Mitigating Risks

A robust supply chain is essential, but the right equipment can significantly ease operational pressures in the landscaping industry. Modern landscaping equipment brings numerous advantages crucial for overcoming supply chain challenges.

Automation plays a pivotal role in improving productivity. Automated loaders and mechanized tools are adept at performing physically demanding tasks more efficiently than traditional methods. This not only reduces the need for large crews but also compensates for labor shortages, ultimately speeding up project completion. By streamlining operations, companies can significantly cut down on downtime and adhere to project deadlines.

Enhancing worker safety and morale is another critical benefit of innovative equipment. Reducing repetitive manual tasks with modern machinery helps lower injury risks, boosting employee satisfaction and productivity. This safer and more efficient work environment contributes to long-term workforce stability and enhances a company’s reputation as a value-driven employer, which can be instrumental in attracting top talent.

Supporting year-round flexibility and versatility is also crucial. Equipment engineered to handle various materials—such as mulch, soil, debris, and stone—ensures continuous operation across different seasonal conditions. An example is the Mulch Mule, designed for reliable performance throughout the year. Though it performs exceptionally under normal conditions, operators must remain mindful of the need for occasional adjustments in extreme weather events.

Finally, maximizing return on investment (ROI) is a strategic advantage of advanced equipment. While the initial cost may be significant, the streamlined workflows, reduced labor expenses, and increased project capacity it provides ultimately justify the investment. Durable and flexible machinery supports efficient scaling of operations, even amidst challenging economic climates. Additionally, equipment with improved longevity and lower maintenance costs further contributes to an impressive long-term ROI.

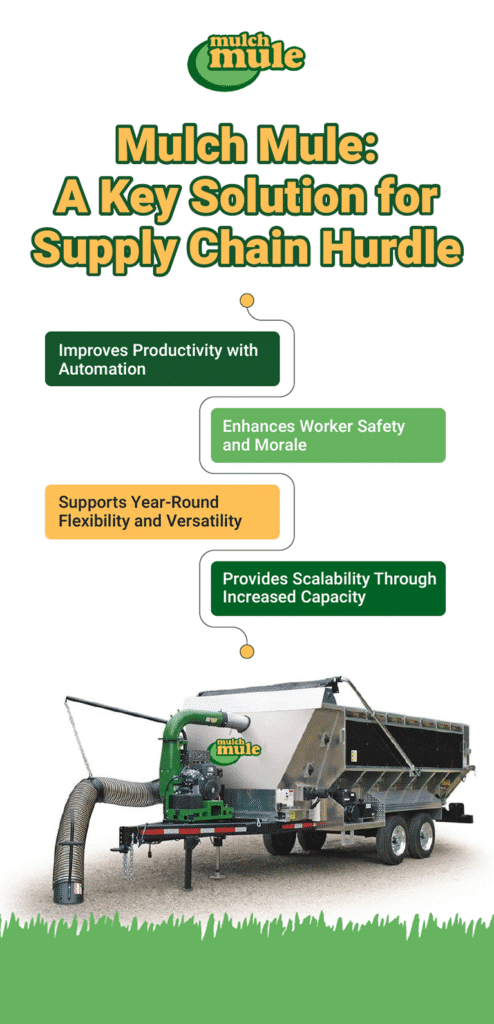

How Mulch Mule Helps Overcome Supply Chain Challenges

Innovative equipment such as the Mulch Mule addresses many of the operational hurdles caused by supply chain disruptions. Here’s how it makes a difference:

Streamlined Material Distribution

- The Mulch Mule features a large-capacity 15-cubic-yard hopper, a high-output curbside discharge conveyor, and a live floor system powered by a robust Honda GXi390 engine.

- The rapid unloading process reduces idle time on job sites, which is vital when every minute counts during scheduling challenges.

- Its design minimizes spillage and ensures even distribution of materials, saving both time and labor.

Labor Optimization and Workforce Relief

- By automating repetitive tasks, the Mulch Mule reduces dependency on manual labor.

- This automation leads to increased productivity and decreases the risk of worker fatigue and injuries.

- Companies can reallocate their workforce to higher-skill tasks that add value to the project, enhancing overall operational efficiency.

Year-Round Flexibility and Versatility

- Attachments and upgrades for the Mulch Mule trailer are designed to efficiently handle various materials for landscaping projects throughout the year, the Mulch Mule supports continuous operation under normal conditions. Operators should remain mindful that, as with any outdoor equipment, particularly severe weather conditions can require extra care or adjustments, though routine performance is generally maintained.

Supporting Scalability and Business Growth

- Efficient material handling and rapid unloading enable shorter project timelines and an increased capacity to take on additional work.

- This efficiency helps companies expand operations while keeping overheads in check, even when facing supply chain challenges.

- By investing in such advanced tools, companies signal their commitment to innovation and operational excellence, attracting more clients and strategic partnerships.

Strengthening Resilience for Today and Beyond

Supply chain challenges in landscaping may be inevitable in the coming years, but they are not insurmountable. By diversifying material sources, enhancing supplier relationships, and adopting flexible, proactive strategies, businesses can protect their operations from disruptions. Embracing innovative equipment like the Mulch Mule further boosts efficiency by automating labor-intensive tasks and streamlining material handling.

While the Mulch Mule is engineered for robust, year-round performance and is designed to support continuous project progress under typical conditions, operators should remain mindful that, as with any outdoor machinery, particularly severe weather conditions may require additional operational considerations. With careful planning and diligent maintenance, businesses can mitigate potential impacts and keep projects on track.

The evolving landscape demands that businesses remain agile and forward-thinking. It is vital to continuously assess operational processes, invest in cutting-edge technology, and foster a culture of collaboration both internally and with industry partners. Now is the time to re-evaluate your operational strategy and build a more resilient business foundation. Transform your approach by integrating advanced tools and leveraging strategic innovation—your future success in the landscaping industry depends on it.

Take actionable steps today to safeguard your projects against the uncertainties of supply chain disruptions. Strengthen your relationships, invest in technology, and adopt flexible strategies to keep your business competitive in an ever-changing market. With the right mindset and tools, this can be a year of opportunity, growth, and enhanced operational efficiency. Learn more about Mulch Mule’s capabilities and see it in action across various conditions and reach out to get a quote today.