Landscaping is a physically demanding industry where strenuous tasks like lifting heavy materials, repetitive bending, and long hours in extreme weather can quickly lead to injuries such as back strain, joint pain, and muscle fatigue. These hazards not only pose physical risks but can also result in higher labor costs and lower team morale. Fortunately, landscaping businesses can reduce these challenges through proper training, streamlined workflows, and investing in modern, ergonomically designed equipment.

In this article, we examine the common injury risks in landscaping and present actionable strategies and smart solutions to create a safer, more efficient work environment for your landscaping crew.

The Physical Demands of Landscaping

Landscaping involves constant physical activity. Tasks such as lifting bags of mulch, shoveling soil, pushing wheelbarrows, and raking debris require repeated exertion. Over time, these motions can lead to chronic issues like back pain, tendonitis, and joint discomfort. Working on uneven terrain or in extreme temperatures can exacerbate fatigue, dehydration, and heat-related illnesses. Such challenges affect employee health, hinder productivity, and disrupt project timelines.

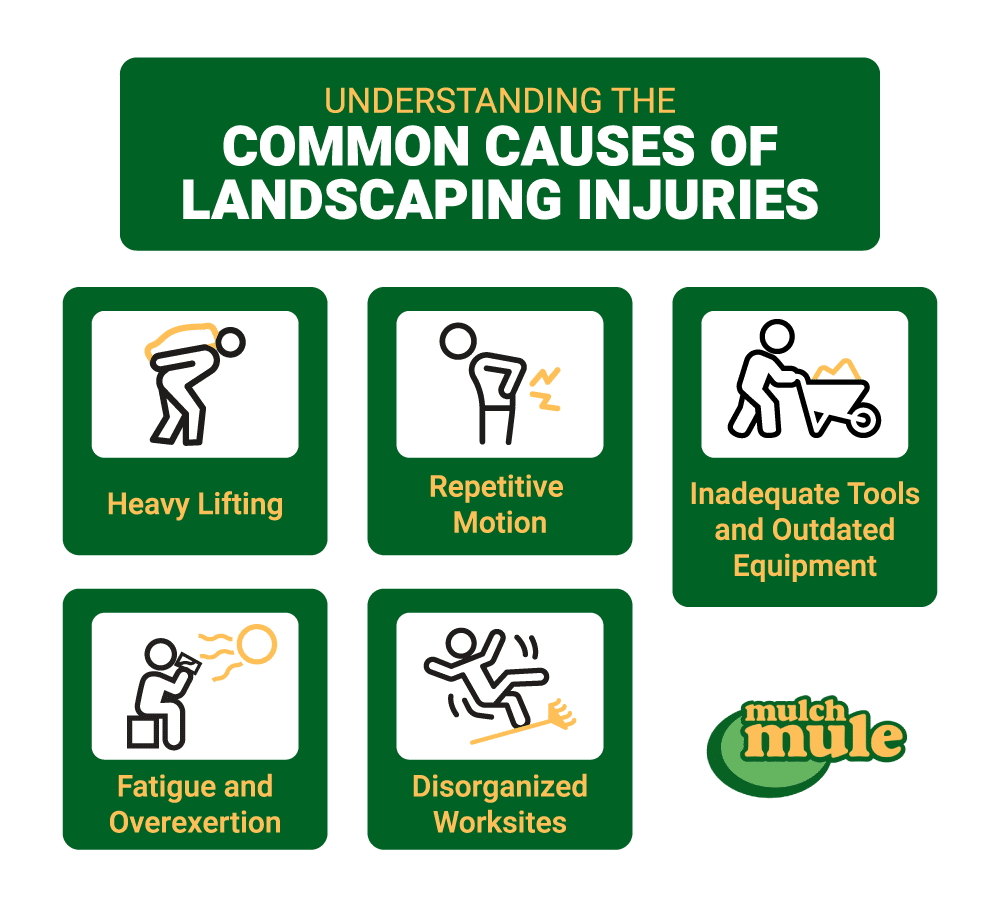

Common Causes of Landscaping Injuries

Several factors contribute to injuries on landscaping jobsites, such as:

Heavy Lifting

Frequent handling of bulky materials like mulch, soil, and stones puts sustained strain on the back, shoulders, and knees. Improper lifting amplifies the risk of muscle tears and chronic pain.

Repetitive Motion

Repeated bending, lifting, and pushing often result in joint pain, tendonitis, and muscle fatigue. Lack of rest intensifies these issues, diminishing productivity over time.

Inadequate Tools and Outdated Equipment

Using poorly maintained or outdated tools forces workers to exert more effort, which can lead to awkward postures and inefficient manual labor. This situation heightens the risk of slips, cuts, and other mishaps.

Fatigue and Overexertion

Long hours without sufficient breaks lead to fatigue, diminishing focus and increasing the vulnerability to accidents. Extreme weather conditions and inadequate hydration further compound exhaustion.

Disorganized Worksites

Cluttered spaces and suboptimal material storage create trip hazards, falls, and collisions. These on-site disarray issues elevate the likelihood of injuries.

Each of these factors underscores the importance of structured safety practices in landscaping work environments. Recognizing these scenarios is a first step toward implementing effective injury reduction measures.

Best Practices for Reducing Injuries

Crafting a safer landscaping environment requires a combination of proactive steps, training, and policy development. Here are some proven approaches:

Comprehensive Employee Training

Regular education on ergonomic techniques and safe lifting practices is essential. Hands-on demonstrations and periodic refreshers equip crew members with the know-how to handle materials safely. Conduct ongoing assessments that allow employees to practice hazard recognition, adopt proper body mechanics, and address potential risks before they escalate.

Emphasize Rest and Hydration

Scheduling regular breaks helps alleviate fatigue and prevent dehydration. Providing access to water and shaded rest areas sustains energy levels, mental clarity, and overall safety. Integrating short breaks as part of the task flow can significantly reduce overexertion and related injuries.

Utilize Personal Protective Equipment (PPE)

Mandatory usage of PPE—such as gloves, work boots, goggles, and hearing protection—goes a long way in shielding workers from hazards. Ensuring that PPE is well-fitted and routinely replaced bolsters its effectiveness in lowering the risk of cuts, falls, and other injuries.

Streamline Workflows

Arranging tools and materials close to the work area reduces unnecessary movements and excessive lifting. Organized storage of materials, such as stacking mulch or stone in a central location, helps contain clutter and enhances jobsite visibility. This approach lessens the odds of trips, slips, and collisions.

Foster a Culture of Safety

Encouraging open communication about potential hazards and recognizing safe behavior strengthens the work culture. When team members trust that safety concerns will be addressed promptly, they become more proactive in identifying and resolving risks.

Additional Tips for Posture and Equipment Maintenance

Beyond standard safety measures, landscaping businesses should underscore proper posture during all tasks and prioritize scheduled equipment maintenance:

- Promote Neutral Spine Alignment: Encouraging workers to keep the spine as neutral as possible reduces stress on the lower back. Demonstrating correct bending and lifting methods can help prevent common musculoskeletal imbalances.

- Rotate Tasks Frequently: Switching tasks every hour or two can limit repetitive motion injuries by preventing overuse of specific muscle groups.

- Maintain Equipment Consistently: Well-maintained machinery and tools can significantly reduce the physical efforts required on the job. Regular servicing, lubrication, and timely part replacements cut down on unnecessary strain.

- Encourage Early Reporting of Discomfort: Implement an open-door policy where employees can voice any discomfort before it escalates. Timely intervention often prevents minor aches from developing into chronic issues.

By combining these posture and maintenance strategies with broader safety practices, landscaping businesses of all sizes can establish a healthier workplace and improve overall morale.

How Advanced Landscaping Equipment Addresses Safety Challenges

Modern landscaping equipment minimizes jobsite risks and boosts productivity by automating labor-intensive processes. Innovative, ergonomic machinery can alleviate some of the most physically taxing activities. Key benefits include:

- Automated Heavy Lifting: Powered hoists or live-floor trailers help reduce unnecessary back strain.

- Reduced Repetitive Actions: Automated features handle tasks that are otherwise repetitive, thereby lowering injury risk from overuse.

- Improved Precision and Control: Handheld remotes and integrated sensors reduce manual rework and mitigate potentially hazardous maneuvers.

- Enhanced Safety Features: Auto shut-offs, warning systems, and obstruction sensors help mitigate accidents on the jobsite.

By integrating advanced machinery, landscaping operations can streamline workflows and reduce the number of injury-related setbacks.

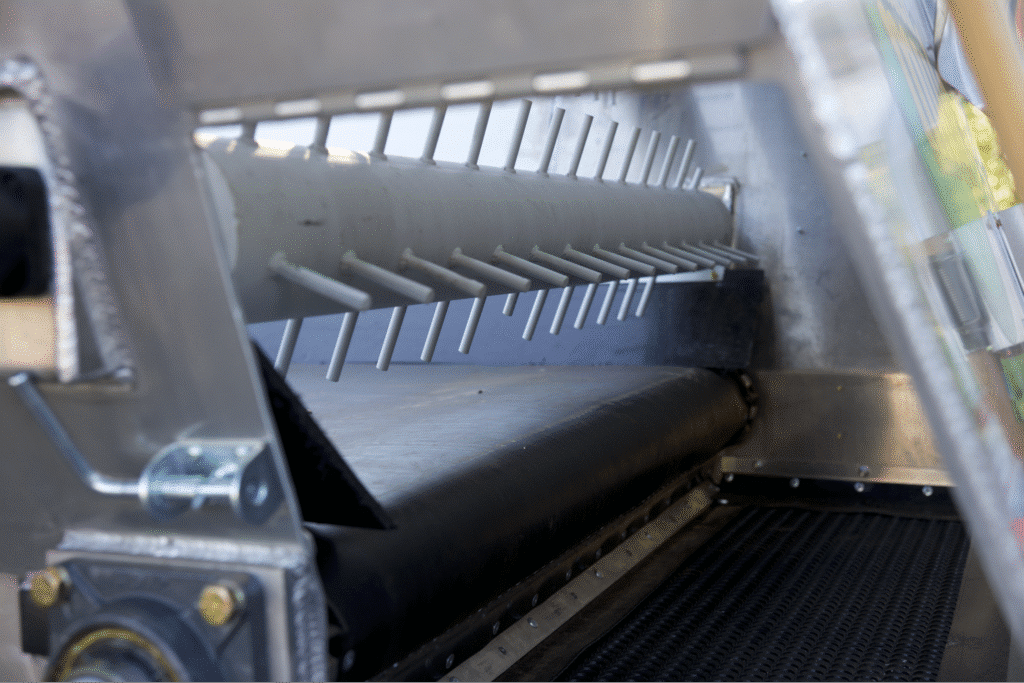

Introducing the Mulch Mule: Transforming Efficiency and Safety

A prime example of modern equipment designed to tackle safety concerns is the Mulch Mule trailer. Specifically engineered for landscape material handling, the Mulch Mule addresses numerous physical challenges:

- 15-Cubic-Yard Aluminum Hopper

- Reduces manual loading by holding large amounts of landscaping materials like mulch, soil, and debris.

- Live floor system with rapid discharge

- Speeds up unloading, thereby minimizing the need for operators to perform heavy lifting.

- Optional vacuum debris loader

- Simplifies cleanup by drawing in leaves and lighter waste, reducing repetitive raking or bagging.

- Curbside discharge and handheld wireless remote

- Streamlines material placement, ensuring precise distribution with less manual shoveling.

Moving and distributing materials is a labor-intensive task. The Mulch Mule is designed from the ground up for management of all types of bulk material and engineered to efficiently automate those back-breaking tasks.

Watch the video below to learn how Mulch Mule can take the load off your employees and pay for itself in the long run by increasing overall profits for your business over time.

Specific Ways the Mulch Mule Improves Jobsite Safety and Efficiency

The Mulch Mule offers targeted solutions to typical landscaping issues:

- Rapid Material Discharge: The live floor system expedites unloading, reducing the physical strain on workers.

- Reduced Physical Labor: With less shoveling and manual lifting, the risk of back strain and repetitive motion injuries is lowered.

- Precision and Control: A remote control enables more accurate material placement, minimizing the need for extra hands to reposition heavy loads.

- Streamlined Cleanup: Features like the optional vacuum debris loader and curbside discharge allow crews to clear debris quickly without excessive physical effort.

- Optimized Crew Utilization: By reducing labor-intensive tasks, team members can focus on other critical assignments, potentially increasing overall business capacity.

Several customers have reported higher project throughput and fewer worker injuries when using Mulch Mule solutions—a benefit for both employee well-being and business growth.

Boosting Profitability by Investing in Safer Equipment

Investing in safety-focused equipment like the Mulch Mule can yield multiple benefits. Reducing manual labor helps decrease injury incidents, which in turn supports consistent productivity. Fewer disruptions allow crews to complete more jobs on time, potentially increasing overall revenue. Moreover, employees facing fewer physical challenges tend to be more engaged and invested in delivering quality work.

Although modern tools require an initial investment, the benefits from enhanced workflow efficiencies and the ability to manage more projects often outweigh the costs. Businesses that track safety improvements regularly may experience overall profitability gains, though the specific impact on project turnaround times can vary based on several factors. Additionally, a safer work environment helps attract clients who value efficiency and worker well-being.

Emerging Best Practices and Future Outlook

Progressive landscaping companies are constantly refining their methods and tools. Many leaders are upgrading their safety protocols, integrating new technologies for real-time monitoring, and conducting systematic risk assessments. Regular safety meetings and evaluations, updated on-site supervision, and continual review of procedures all contribute to a safer environment. These steps allow organizations to maximize the benefits of advanced equipment while ensuring that each team member remains secure and productive.

Building a culture of continuous safety improvement involves open communication and a commitment to adapting practices based on practical experience and evolving industry standards.

Embracing Digital Transformation for Enhanced Safety

Digital transformation is reshaping landscaping safety. IoT devices and wearable sensors can alert supervisors if a worker shows signs of fatigue or dehydration. In addition, digital tools help in maintaining organized workspaces and ensuring that safety protocols are followed. As technology evolves, these innovations are increasingly accessible, offering landscaping operators—both large and small—the opportunity to modernize their safety practices.

Real-World Benefits and Implementation Tips

Landscaping businesses that implement systematic safety programs for their landscaping crew often see tangible benefits. Monitoring improvements in workflow and safety protocols can contribute to enhanced overall profitability, although the direct influence on project turnaround times may depend on a variety of factors. Regular audits, real-time monitoring devices, and an open feedback loop help teams identify risks before they escalate and adjust practices accordingly. This balanced approach of traditional safety fundamentals combined with modern digital solutions fosters a secure work environment and improves operational outcomes.

Transforming Landscaping with Smarter, Safer Solutions

Reducing jobsite injuries is not only a moral responsibility—it’s a strategic decision that can boost productivity, lower labor costs, and enhance employee satisfaction. By emphasizing comprehensive training, methodical workflows, and advanced equipment like the Mulch Mule, landscaping businesses can create a safer, more efficient work environment. This approach reduces physical strain, streamlines project timelines, and builds a more motivated team—essential factors for long-term success.

If you’re ready to explore tangible ways to improve your operations, consider learning more about advanced landscaping solutions that prioritize both safety and efficiency. Contact Mulch Mule today to learn how this advanced equipment can boost safety and efficiency for your crews.