Landscaping professionals face significant challenges when accessing job sites with tight spaces, steep slopes, and delicate turf. Mulch trailer maneuverability becomes critical when crews must navigate narrow gates and confined areas while handling large quantities of bulk materials, as standard equipment can increase labor demands and the risk of property damage. Mulch Mule’s specialized mulch trailers, designed for optimal maneuverability, transform these challenges into opportunities for improved efficiency and safety. This article explores practical strategies and key equipment features that streamline operations, reduce labor, and protect client properties.

The Importance of Maneuverability in Landscaping

Landscaping crews rarely struggle with the work itself—most of the friction comes from getting trailers and materials into position. Tight access points, uneven slopes, and soft turf all make it harder to move equipment efficiently. Narrow driveways, small gates, and tight streets limit where a trailer can safely turn or back up. Slopes reduce traction and stability, increasing the risk of tipping or load shifts. Soft or finished turf is easily rutted or torn by heavy equipment, especially when the ground is wet.

When trailers aren’t designed to handle these conditions, crews are forced to park farther away, haul material by hand, take longer routes, or avoid certain access paths altogether. The result is slower production, higher labor costs, and a greater chance of property damage—exactly what this blog is designed to help solve.

Key Trailer Features for Navigating Tight Areas

Several design elements available on some mulch trailers directly address maneuverability concerns. By focusing on accessibility and simplified operation, these trailers offer tangible benefits for professionals working in confined environments.

Compact Design for Maximum Accessibility

A compact design with a narrower width and shorter wheelbase makes it easier to navigate through tight garden gates and narrow driveways. A reduced turning radius minimizes the risk of clipping obstacles, ensuring a safe and smooth operation in confined spaces.

Live Floor System for Efficient Unloading

A live floor system improves material handling by moving materials automatically toward the discharge point. This mechanism bypasses the need for manual shoveling and allows for quick, controlled offloading—even in limited spaces. Its precise operation saves both time and labor while reducing spillage.

Curb-Side Discharge for Controlled Placement

A curb-side discharge system is designed to allow operators to offload materials directly into wheelbarrows in predefined areas, reducing the need to reposition the trailer in many situations. In certain residential neighborhoods or busy commercial zones with limited maneuvering room, this feature can help maintain traffic flow and protect surrounding property, although the benefits may vary depending on specific site conditions.

Remote-Controlled Operation for Precision

Many advanced mulch trailers, including the Mulch Mule, feature wireless remote controls that allow operators to manage key unloading functions from a safe distance. With these remotes, crews can start or stop the conveyor, adjust conveyor speed and direction, and control material flow right from where they stand. This lets operators fine-tune material placement in real time, ensuring mulch is delivered exactly where it’s needed, even in tight spaces, while keeping the operator safely out of harm’s way and boosting efficiency on the job.

Overcoming Slopes and Uneven Terrain

Landscaping projects often involve slopes and uneven ground where stability is a vital concern. Proper equipment design—combined with thoughtful operational strategies—can significantly reduce risks.

Hydraulic Trailer Jacks for Stability

Hydraulic trailer jacks allow operators to quickly adjust the trailer’s height to match ground contours. This stabilization capability is essential during loading, unloading, and stationary periods on uneven surfaces, as it minimizes the risk of tipping while preserving material stability.

Heavy-Duty Suspension for Smooth Operation

A robust heavy-duty suspension system distributes weight evenly across the trailer, preventing undue stress on any single component and reducing the bounce effect on rough surfaces. This enhances both safety and equipment longevity—even when carrying heavier materials like soil and mulch.

Tips for Safe Operation on Slopes

When traversing slopes, it is crucial to:

- Maintain a steady speed without abrupt changes.

- Choose paths with firm ground whenever possible.

- Unload materials gradually to prevent sudden shifts in weight.

These practices, combined with hydraulic jacks and sturdy suspension, enable safe navigation of challenging terrain.

Preserving Soft Turf and Delicate Landscapes

Protecting sensitive turf and landscaped areas is a top priority for landscaping professionals. Heavy equipment has the potential to cause surface damage, but thoughtful trailer design and operating protocols can mitigate these risks.

Balanced Weight Distribution

Trailers engineered with balanced weight distribution prevent excessive pressure on soft turf. Even load dispersal reduces the risk of deep ruts and soil compaction, maintaining the health and appearance of the landscape.

Precision Discharge for Controlled Placement

A precision discharge mechanism helps ensure that materials are placed only where intended. This targeted approach minimizes manual intervention and reduces the potential for turf damage when distributing mulch or other bulk supplies.

Operational Strategies for Turf Preservation

In addition to using advanced equipment, landscapers protect delicate areas by:

- Planning routes over hard surfaces whenever possible.

- Executing wide, deliberate turns.

- Gradually adjusting the trailer’s discharge position.

These strategies collectively preserve lawn integrity while maintaining operational efficiency.

Practical Strategies to Optimize Trailer Maneuverability

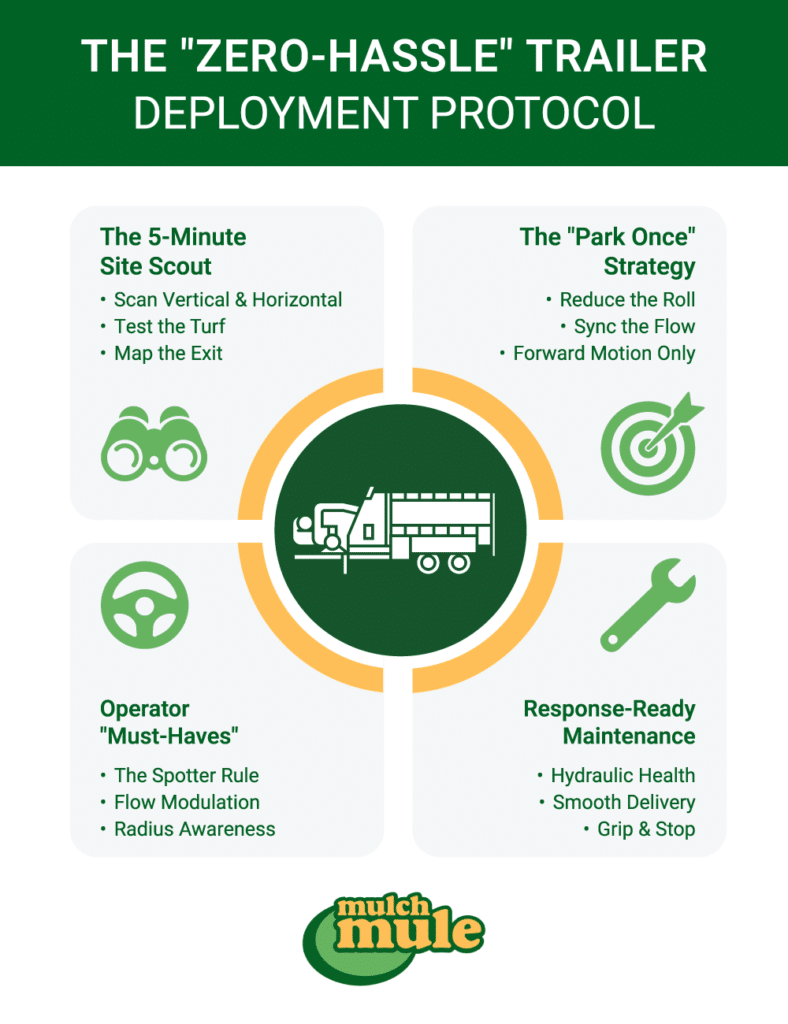

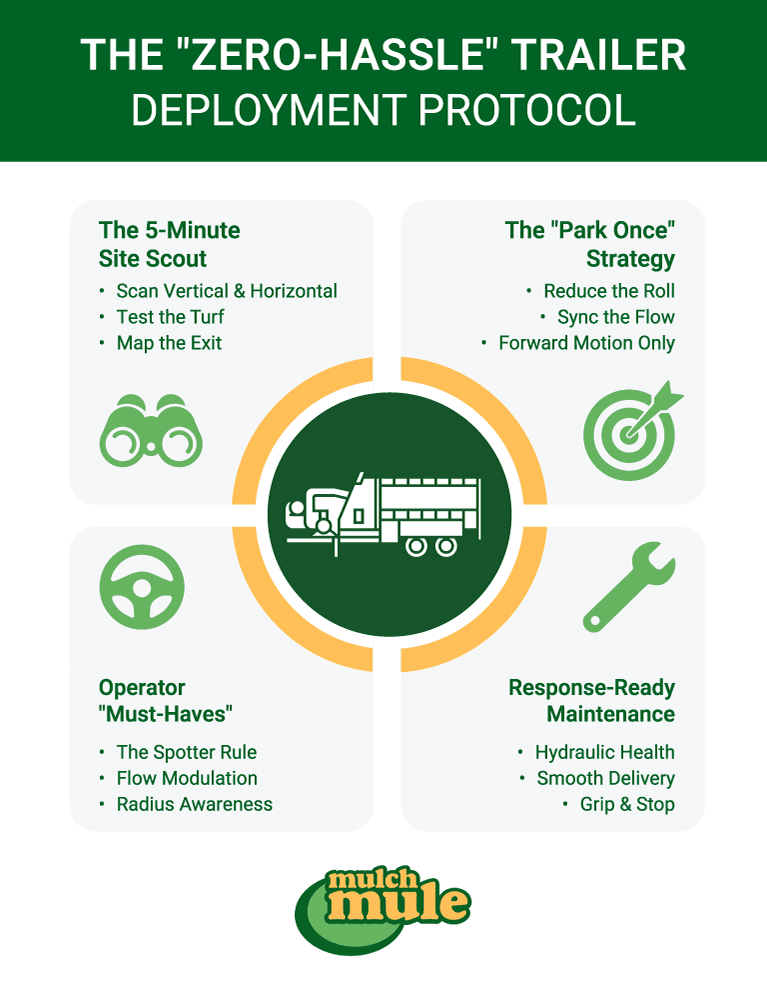

Even the best mulch trailer performs better when crews use it with a plan. These strategies help you get the most out of a Mulch Mule (or any mulch trailer) on tight, complex job sites.

Site Assessment

Before the trailer ever pulls in, walk the property and identify:

- Access points: Measure or visually confirm gate widths, driveway tight spots, and any overhanging branches or structures.

- Terrain: Note slopes, soft turf, wet areas, and any uneven ground that could affect stability.

- Traffic flow: Consider where crew vehicles, the trailer, and pedestrians will move so you’re not blocking driveways or walkways.

Use this assessment to decide:

- Whether to back in or pull through

- Where to park or stage the trailer

- Whether you’ll primarily use curb‑side discharge, rear discharge, or a combination

A 5‑minute walkthrough can prevent costly backing maneuvers, turf damage, and wasted time.

Strategic Material Placement

Planning where material will be dropped is just as important as planning how you’ll get there.

- Stage close to the work zone: Position the trailer so the live floor and discharge system can send mulch directly where crews need it, reducing wheelbarrow runs.

- Minimize repositioning: Choose one or two optimal parking spots instead of moving the trailer repeatedly through tight areas.

- Sequence your drops: If you’re servicing multiple beds or sections, discharge material in an order that matches your crew’s workflow so they’re always moving forward—never backtracking.

Thoughtful placement uses the trailer’s curb‑side and precision discharge to reduce labor, keep paths clear, and minimize ruts.

Operator Training

Even advanced trailer features only pay off if operators know how to use them.

Train your team on:

- Core controls: Live floor speed, start/stop, hydraulic jack operation, discharge adjustment, and any remote‑control functions.

- Tight‑space techniques: Backing into narrow drives, turning radius awareness, and safe spotting with a ground guide.

- Material control: How to modulate live floor and discharge speed to avoid over‑dumping or spillage in confined areas.

A short, structured training session—plus periodic refreshers—helps operators work faster, avoid property damage, and fully leverage Mulch Mule’s maneuverability features.

Routine Equipment Maintenance

Well‑maintained equipment is easier and safer to maneuver.

Focus on:

- Hydraulic system checks: Inspect fluid levels, hoses, and fittings so hydraulic jacks and drive components respond predictably on slopes and uneven ground.

- Live floor and discharge components: Clear debris, check chains/belts, and verify smooth operation to avoid jerky starts and stops in tight areas.

- Suspension, tires, and brakes: Proper inflation, tread, and braking performance are critical when navigating narrow driveways, soft turf, and hills.

Building these checks into a regular maintenance schedule reduces downtime, improves control, and keeps your trailer responsive in the most challenging conditions.

Considerations Before You Invest in a Mulch Trailer

While mulch trailers can dramatically improve efficiency, there are some considerations to keep in mind:

- Initial Investment: Purchasing specialized equipment often requires a significant upfront cost. Businesses should evaluate how quickly they can recoup this expense through labor savings and increased productivity.

- Size Restrictions in Extremely Tight Urban Sites: Even a compact trailer may face limitations in severely confined urban environments. Site evaluations and careful planning remain essential.

- Operator Skill Requirements: Advanced features like remote-controlled operation and hydraulic jacks can be highly beneficial, but they also require training and experience for safe, efficient use.

Recognizing these potential drawbacks ensures a balanced view and helps landscaping professionals make well-informed decisions about integrating mulch trailers into their operations.

How Mulch Mule Boosts Efficiency and Profitability

Innovative equipment by Mulch Mule provides a competitive edge by streamlining material handling and reducing labor costs. Features like a live floor system and remote-controlled operation speed up job completion and provide precise material placement. The ability to operate year-round with minimal downtime further enhances profitability.

By automating physically demanding tasks and lowering the risk of workplace injuries, Mulch Mule trailers help businesses maintain crew morale and reduce operational expenses. The result is a reliable, versatile solution that expands capacity and enables companies to confidently take on more projects.

Click the video below to hear Keegan Minard, the owner of Minards Landscape, talk about his experience starting out in the landscape design industry and how the Mulch Mule has helped him. Before Mulch Mule they were typically doing 50 to 80-90 yards a mulch a day. Since purchasing the equipment they are seeing double the productivity with the same amount of workers.

Frequently Asked Questions About Mulch Trailers and Maneuverability

Do mulch trailers damage grass?

Mulch trailers don’t have to damage grass when they’re used correctly. Damage usually comes from excessive weight on soft turf, sharp turns, or repeated passes over the same area. Trailers designed with balanced weight distribution and appropriate tires, like Mulch Mule trailers, help reduce ruts and compaction. Planning routes over hard surfaces when possible, making wide, deliberate turns, and minimizing unnecessary repositioning further protects turf.

How do I safely use a mulch trailer on slopes?

Safe slope operation starts with understanding your site and your equipment limits. Whenever possible, travel straight up and down slopes rather than across them, avoid sudden speed changes, and use low, steady speeds. Stabilize the trailer with hydraulic jacks before loading or unloading on uneven ground, and discharge material gradually to prevent sudden weight shifts. Always follow the manufacturer’s slope and load recommendations for your specific trailer.

What’s the difference between a mulch trailer and a dump trailer?

A standard dump trailer is designed to tip and release material in one large load. A mulch trailer, such as a Mulch Mule, is purpose-built for landscaping and controlled material placement. It typically includes a live floor system, curb-side or precision discharge, and features like remote operation and hydraulic jacks. This allows for slow, targeted unloading along beds or walkways, reducing manual shoveling, cleanup, and the risk of property damage in tight spaces.

How big of a mulch trailer do I need for residential routes?

For most residential routes, a 10–15 cubic yard mulch trailer provides a good balance between capacity and maneuverability. Smaller contractors or those working in very tight neighborhoods may prefer a more compact unit for easier access through narrow driveways and cul-de-sacs. Larger crews servicing multiple properties per day often benefit from higher-capacity trailers, like a 15-yard Mulch Mule, to reduce trips back to reload. Consider average job size, gate and driveway widths, and tow vehicle capacity when choosing trailer size.

Transform Optimized Mulch Trailer Maneuverability into Profit

Navigating tight spaces, steep slopes, and delicate landscapes requires equipment that combines thoughtful design with practical operating strategies. Trailers featuring compact builds, live floor systems, hydraulic adjustments, and precision discharge systems provide the flexibility needed to meet these demands. By integrating these innovations into daily operations, landscaping professionals can cut labor costs, protect client properties, and accelerate project timelines.

Transform your operations with Mulch Mule and experience a new level of performance in efficiency and profitability. Empower your team to work smarter and ensure your business remains competitive in today’s fast-paced landscaping market. Reach out today to schedule a demonstration and unlock your company’s full potential.