In the landscaping industry, contractors often face pressing demands—tight deadlines, increasing material needs, and the need to maintain high-quality results on every jobsite. When you add the challenges of handling bulk materials like mulch, soil, leaves, or stone, doing everything manually can prove both time-consuming and costly. To stay competitive, many are turning to specialized solutions such as the Mulch Mule trailer and other advanced mulch machines to automate traditionally labor-intensive tasks.

Using a modern mulch machine can significantly streamline material distribution, helping contractors reduce labor costs, speed up project timelines, and boost jobsite safety. With features such as a 15 cubic yard hopper capable of discharging in just 45 seconds and the ability to fill a wheelbarrow in as little as 3–6 seconds, equipment like the Mulch Mule demonstrates how quickly projects can be completed without straining your crew. This efficiency translates into shorter project durations, improved profitability, and a better work environment for employees.

Below, we explore how these machines suit today’s landscaping demands, from their innovative features and year-round uses to practical strategies for employing them effectively on any jobsite. Whether you operate a small local business or lead a large-scale contracting team, understanding the transformative value of mulch machines will position you at the forefront of a competitive marketplace.

The Use for Mulch Machines in Modern Landscaping

According to an industry study by The Freedonia Group, demand for landscaping services continues to rise, making it vital to optimize efficiency and throughput wherever possible.

Like many industries, landscaping has embraced new technologies to optimize time and resources. Traditional methods—such as filling wheelbarrows or using shovels—can slow down progress and cause fatigue or injury.

According to OSHA, overexertion and musculoskeletal issues are common in this sector. The National Safety Council also underscores the significance of reducing injuries in physically demanding fields. Without the right equipment, contractors risk higher injury rates, longer project timelines, and diminished profitability.

In contrast, modern mulch machines automate core material logistics. They transport and discharge mulch, debris, or aggregates quickly, allowing teams to focus on value-added activities such as site preparation or fine detailing. Because these machines handle the heavy lifting and distribution, your crew experiences less physical strain, contributing to a safer, more productive work environment.

For example, a landscaping contractor in Ohio might find themselves juggling multiple high-volume jobs during peak season. Before investing in a mulch machine, this contractor might have used manual labor to load and transfer bulk materials, stretching the workday into late hours to keep up with demands.

By implementing a live floor system and a robust vacuum debris loader, that same contractor could reduce loading times and cut labor costs—thereby reducing physical strain and overtime. The positive ripple effects—less overtime, fewer injuries, and quicker job turnover—reinforce why modern mulch machines are a game-changer for contractors seeking to optimize their workflows.

Innovative Features of Modern Mulch Machines

Cutting-edge mulch machines incorporate powerful features that address the key pain points in bulk material handling:

Live Floor System

A live floor system uses an internal conveyor to propel materials toward the discharge point, optimizing the flow and precision of distribution. This design prevents the need for manual raking or pushing mulch to the trailer’s edge, reducing labor-intensive steps. It also helps minimize spillage and environmental dust, making your operations cleaner and more professional.

15 Cubic Yard Capacity

Large hoppers—often up to 15 cubic yards capacity—mean fewer refills and less downtime. For contractors juggling multiple projects, quick offloading is essential to stay on schedule. If you’re tasked with refreshing mulch beds at multiple commercial properties in a single day, a high-capacity hopper can slash the number of stops you need to make for reloading, allowing you to move swiftly from one location to the next.

Vacuum Debris Loader

Many machines include an optional vacuum debris loader attachment. This lets crews swiftly transition from material distribution to cleanup, ensuring the jobsite remains orderly. Rather than needing separate pieces of equipment for mulch placement and leaf removal, this consolidated solution handles both, reducing equipment transportation costs and downtime.

Heavy-Duty Suspension

Built for rugged terrain and heavy usage, a sturdy heavy-duty suspension system and hydraulic jack keep the trailer stable, even when transporting large loads under diverse conditions. By maintaining trailer balance on uneven ground or winding pathways, your crew can operate more confidently and focus on accurate material placement instead of worrying about trailer tipping or shifting.

Attachments and Upgrades

With a machine like the Mulch Mule, you don’t just get a single-purpose tool. Various attachments and upgrades can further streamline your operations, such as lighting kits for evening or early morning projects, secure tarping systems to keep materials contained, and remote controls that let crew members manage discharge without having to stand directly next to the trailer. These add-ons fine-tune the overall efficiency by tailoring the machine to your specific workload, whether you’re in a busy suburban neighborhood or a large commercial site.

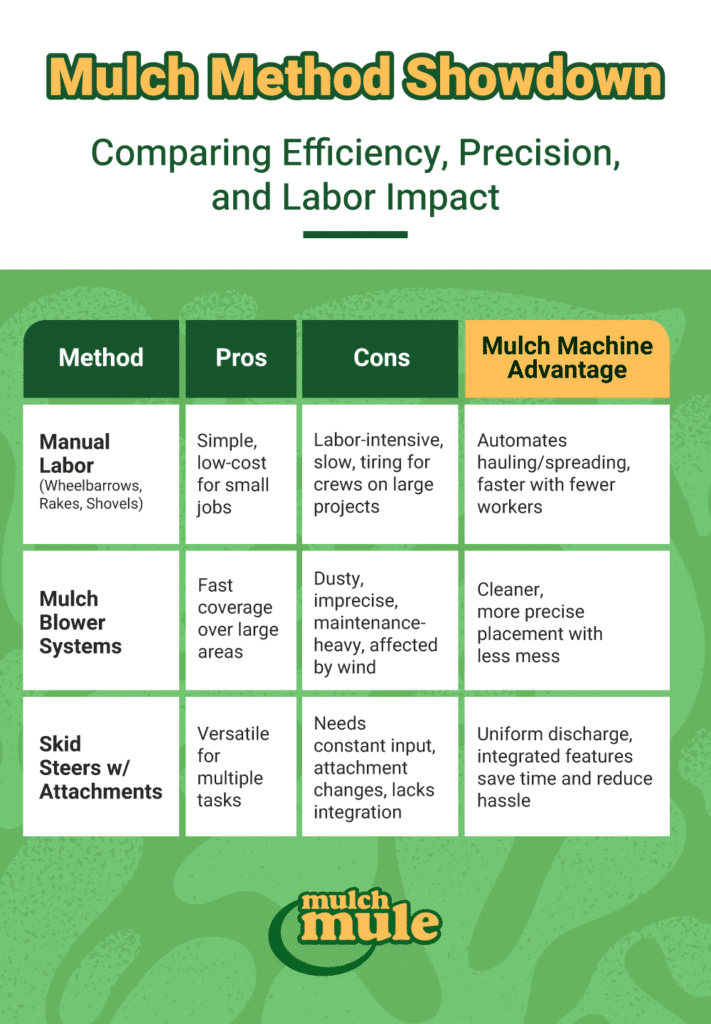

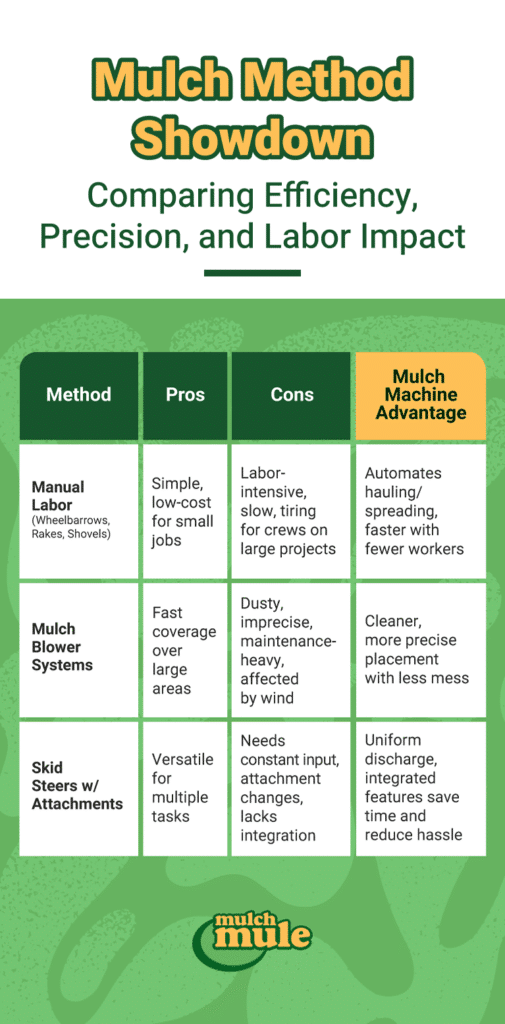

Comparing Mulch Machines to Traditional Methods

Not all landscaping tasks require specialized machinery, but when efficiency and volume matter, the difference can be striking:

Manual Labor with Wheelbarrows

While wheelbarrows, rakes, and shovels are standard for small-scale tasks, these methods can exhaust crews on bigger jobs. Mulch machines lighten the load by automating much of the hauling and spreading process. Tasks that once took multiple workers several hours might now be completed by fewer employees in half the time.

Mulch Blower Systems

Mulch blower systems rely on compressed air to blast mulch into place. Though effective for covering large areas, they can generate excess dust, require specialized maintenance, and often lack the precise placement that conveyor-driven systems provide. In areas prone to windy conditions or near delicate plants, over-spray from a blower can be problematic, rendering conveyor-based solutions more appealing.

Skid Steers with Attachments

Skid steers are versatile but may require constant operator input for exact distribution. A dedicated mulch machine excels at uniform discharge, saving time and reducing spillage. While a skid steer might also manage debris and stone, it generally lacks the integrated features—like a vacuum loader or live floor—that streamline multiple tasks. This means crews might spend more time swapping attachments or reconfiguring the skid steer for different phases of a project.

Contractor satisfaction and retention rates are known to improve significantly when labor-intensive tasks are minimized. By eliminating repetitive, strenuous chores, a mulch machine helps reduce the physical toll on workers, improves morale, and fosters a more positive work culture.

Boosting Landscaping Profitability Through Efficiency

Mulch machines deliver clear outcomes that can enhance a contractor’s bottom line:

Lower Labor Requirements

By automating repetitive tasks, you can operate with smaller crews or focus personnel on skilled activities—an approach that helps conquer landscaping labor challenges and cuts payroll costs. If a single operator can manage the machine’s discharge system, your other team members are free to concentrate on pruning, planting, or irrigation work, adding more revenue-generating tasks to each job.

Heightened Safety

Fewer injuries translate into fewer insurance claims and stronger morale. Reducing physically demanding processes also aligns with broader proactive safety measures. Contractors who prioritize worker well-being often build stronger reputations, fostering trust with both employees and clients. A safe and healthy workforce is more likely to deliver high-quality work consistently, leading to repeat business and referrals.

Streamlined Operations

Faster loading and offloading mean you can wrap up jobs sooner and take on more clients. This is especially beneficial for time-sensitive contracts and during peak seasons. In busy spring months, for instance, you might schedule multiple mulch refreshes in a single day across different areas of town. With efficient unloading, you can ensure timely results and keep projects on track.

Faster ROI

Equipment like the Mulch Mule can pay for itself by enabling higher throughput, greater scheduling flexibility, and reductions in overtime. Its quick-discharge system (45 seconds to empty a full hopper) and rapid wheelbarrow fills (3–6 seconds) multiply efficiency gains. Contractors often report that the initial cost is quickly offset by cumulative savings in labor and the ability to bid on more projects.

The Mulch Mule is designed to transport and distribute soil, mulch, leaves, debris, stone and aggregate to save you time and money. With innovative features like the live floor system, curb-side discharge and powerful Honda GXi390 Engine, the Mulch Mule can do it all…and better.

Some contractors using mulch machines have reported noticeable reductions in labor hours for distribution tasks, based on anecdotal feedback from Mulch Mule’s customers. These efficiency gains can translate to shorter project timelines and reduced overall labor demands, contributing to improved profitability.

In the video below, Eberhardt Landscaping shares their experience with the Mulch Mule and working with Brown Equipment Company. Their leadership team talks about the solutions the Mulch Mule provides for them as a company and the increase in morale for their team.

Year-Round Applications for Landscaping Contractors

Though primarily associated with mulch distribution, these machines have utility well beyond peak mulch season. With the ability to handle leaves, topsoil, debris, stone, and other bulk materials, they allow contractors to tackle diverse projects and maintain profitability all year:

Seasonal Cleanup

In spring, you can blend topsoil into planting beds more efficiently; in autumn, vacuum up leaves and debris with minimal downtime. Performing these tasks with a single piece of equipment cuts back on transportation between jobsites and the logistical headaches of moving multiple machines.

Aggregate Placement

Whether installing driveways, walkways, or decorative rock features, a well-equipped mulch machine can move stone and gravel with high precision. This advantage is particularly helpful in mid-summer, when clients often request minor hardscaping projects. Instead of switching entirely to a different vehicle or device, you can attach upgrades on the same machine.

Debris Removal

The enclosed hoppers and optional attachments make it easier to keep worksites tidy, minimize trips for cleanup, and speed project turnover. If a property manager hires you for large-scale fall leaf removal, the mulch machine’s vacuum loader and quick-discharge live floor system ensure minimal downtime between collection and disposal.

Potential Drawbacks and Considerations

While mulch machines offer remarkable advantages, contractors should also weigh a few considerations:

Initial Investment

The upfront cost can be significant, especially for smaller operations. However, many businesses see a balanced return within a reasonable timeframe as labor savings accumulate. Short-term financing or leasing options may also soften the initial financial impact, making it feasible for contractors looking to scale.

Training Requirements

Operators may need an initial learning curve to handle new controls or features. Scheduling training ensures your team can safely maximize the equipment’s capabilities. This learning period is typically brief, but setting aside time for thorough instruction and practice helps prevent accidents, equipment damage, and inefficient usage.

Maintenance and Parts

Preventive maintenance and timely part replacements are essential for reliable performance. Choosing high-quality equipment with accessible service and warranty options helps mitigate downtime. Having a clear maintenance schedule—perhaps monthly check-ins for conveyor belts and quarterly evaluations of hydraulic components—keeps your machine functioning optimally. If a critical part fails during a busy season, having a quick turnaround for service or replacement is vital to maintain your project timelines.

Storage and Transport Logistics

When not in use, a mulch machine typically requires ample storage space, especially if you have add-on attachments. If you operate in densely populated regions or have limited facility space, plan accordingly. Coordination of transport vehicles or reconfigured garages can help accommodate the machine’s dimensions.

Transform Your Business with a Mulch Machine

In today’s fast-paced landscaping industry, staying competitive means streamlining operations and investing in the right tools. A mulch machine—with a 15 cubic yard hopper capable of discharging in just 45 seconds—can significantly reduce your labor needs, control expenses, and handle a wide array of materials all year. By minimizing physical strain on your team and accelerating turnaround times, you keep both clients and employees satisfied.

Many contractors have found that adopting a productivity-oriented approach anchored by a reliable mulch machine leads to stronger profit margins and a more efficient work environment. Whether you manage a small mowing crew or a sizable team specializing in new site installations, the differences made by advanced material-handling equipment are substantial. Beyond mulch season, you’ll have the flexibility to tackle projects involving debris removal, stone transportation, and seasonal cleanups—an ideal way to keep business thriving even in off-peak months.

If you want to see the Mulch Mule in action, schedule a demo via our ambassador program and learn firsthand how it can revolutionize your operations. To discover more specific details about the equipment, available attachments, or warranty coverage, request product details and take the first step toward transforming your landscaping business.