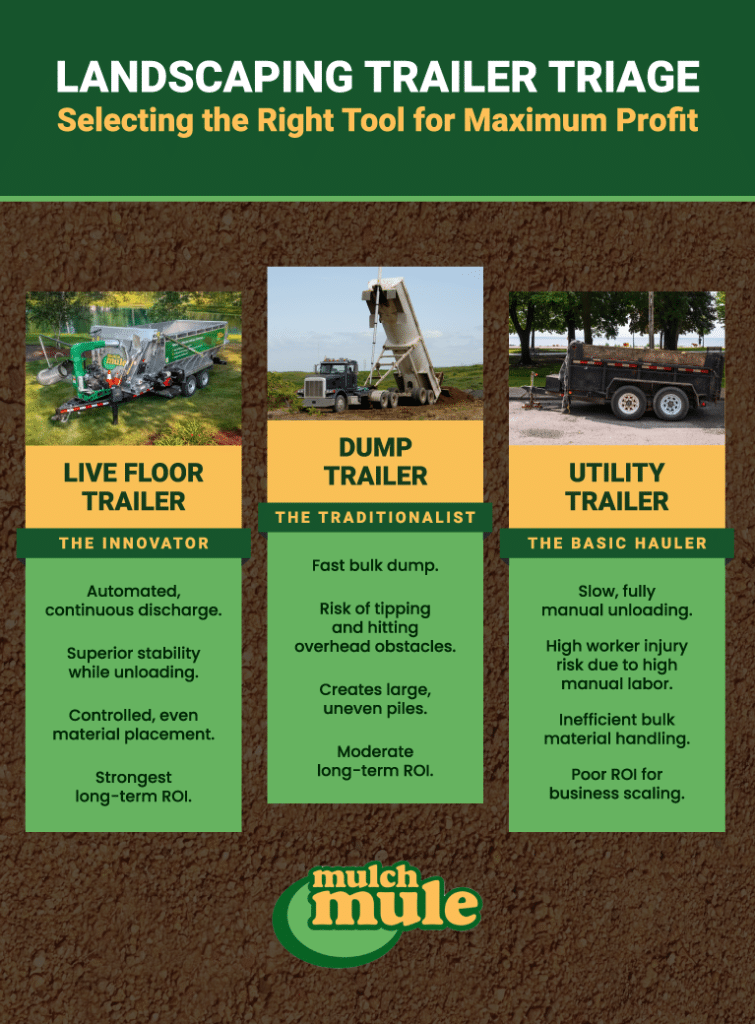

Choosing the right trailer is one of the most critical decisions a landscaping company can make, directly impacting your bottom line. The right equipment can slash labor costs, enhance job site safety, and boost overall productivity. For most professionals, the choice comes down to three main contenders: the innovative live floor trailer, the traditional dump trailer, and the versatile utility trailer.

But how do they stack up against each other in real-world conditions? In this comprehensive guide, we’ll provide a head-to-head comparison of live floor, dump, and utility trailers. We’ll analyze each of the factors that matter most—efficiency, safety, versatility, and return on investment—to help you decide which trailer is the best fit for your landscaping operations.

The Contenders: A Quick Overview

Before diving into the comparison, let’s briefly define our three main types of landscaping trailers.

- Live Floor Trailers: These trailers use a hydraulically powered conveyor system built into the floor to move materials steadily for controlled unloading of bulk materials like mulch, soil, and gravel—without needing to tilt the trailer bed. Depending on the configuration, material can be discharged out the rear or through a curb-side/front chute for easier wheelbarrow loading.

- Dump Trailers: As the traditional workhorse, dump trailers use a hydraulic lift to tilt the entire trailer bed, unloading materials with the help of gravity. They are effective for moving large volumes of material quickly.

- Utility Trailers: Known for their simplicity and low cost, utility trailers are simple flatbeds, often with low walls. They are ideal for hauling equipment, bagged goods, or light-duty materials, but require manual labor for unloading.

A Deeper Dive: How Live Floor Technology Works

While dump and utility trailers operate on simple principles, live floor technology is more advanced. At its core is a hydraulically powered conveyor system embedded in the floor. As the system activates, it shifts materials such as mulch, soil, gravel, or debris to be pushed out evenly toward the rear (or front, depending on configuration) at a controlled pace. This enables the precise, non-tilting discharge that sets it apart.

Key Features of This System:

- Hydraulic Conveyor System: Moves materials smoothly without tilting.

- Controlled Unloading: Adjustable speed and direction improve precision.

- Safe Design: The non-tilting design ensures safety even on uneven terrain and in low-clearance areas.

- Versatility: Handles various materials, from mulch to heavy aggregates.

Head-to-Head Comparison: Which Trailer Performs Best?

Now that we understand the technology, let’s see how these trailers stack up in the key areas that matter most to landscaping professionals.

Efficiency and Speed

- Live Floor: The automated conveyor system allows for rapid, continuous, and controlled material discharge without manual intervention. This ability to reduce reliance on manual labor and ensure faster turnaround times is a critical benefit. The continuous workflow reduces downtime, allowing crews to complete tasks quicker and transition seamlessly to the next job.

- Dump: Fast for bulk unloading, but the “all-or-nothing” gravity-based dump often requires additional time and labor for workers to spread material manually, creating an inefficient second step.

- Utility: The least efficient for bulk materials. Unloading is entirely dependent on manual labor, making it slow, costly, and labor-intensive for the large-scale jobs required for business growth.

Jobsite Safety

- Live Floor: The non-tilting design is the standout safety feature, a clear advantage on sites with uneven ground or limited vertical clearance where dump trailers pose a stability risk. By automating the unloading process, it also dramatically reduces the physical strain on workers and protects them from the heavy lifting injuries common with manual unloading.

- Dump: Poses a significant tipping hazard, especially on soft or uneven terrain. The raised bed can also collide with overhead obstacles like power lines or tree branches, making it unsuitable for many job sites.

- Utility: While the trailer itself is stable, the complete reliance on heavy manual lifting makes it the most likely to cause worker injuries, strains, and fatigue over the long term.

Versatility and Unloading Precision

- Live Floor: Excels in both versatility and precision. It can handle a wide variety of materials—from fine soil to heavy aggregates. Crucially, the controlled discharge allows for precise material placement, making it ideal for applications where even distribution is critical, such as in landscape design and installation.

- Dump: Good for bulk transport of aggregates like gravel or sand but lacks precision. It’s difficult to control the flow, often resulting in one large, uneven pile that requires extra handling.

- Utility: Versatile for hauling equipment, tools, and bagged materials, but unsuitable for precise, bulk material application.

Cost and Return on Investment (ROI)

- Live Floor: While it has a higher upfront cost, the live floor system delivers the strongest ROI. The reduction in labor expenses and increased output yield significant long-term savings. For large-scale tasks that involve frequent bulk material handling, the efficiency gains quickly justify the investment for growing businesses.

- Dump: Represents a mid-range initial investment. It offers some labor savings over a utility trailer but doesn’t match the long-term operational efficiency and safety benefits of a live floor system.

- Utility: Has the lowest initial cost. However, for any business looking to scale, the long-term costs of manual labor for large projects will quickly outweigh the initial savings, limiting profitability

The Professional’s Choice: The Mulch Mule Live Floor Trailer

After comparing the options, it’s clear that for serious landscaping operations, the live floor trailer offers the best combination of efficiency, safety, and ROI. A leading example of this technology is the Mulch Mule.

Notable Features

- 15-Cubic Yard Aluminum Hopper: High-capacity design minimizes trips and increases efficiency.

- Continuous Live-Floor Discharge: A hydraulically powered conveyor provides a steady, controlled flow of material for consistent unloading (instead of a single “dump” release).

- Bidirectional Action: Allows both forward and reverse operation for optimal material management.

- Optional Vacuum Debris Loader: Enhances cleanup efficiency during seasonal tasks.

- Durability and Performance: Built with a Honda GXi390 Engine and a hydraulic jack, ensuring reliable operation in rugged conditions.

Impact on Operations

Using the Mulch Mule can:

- Boost Productivity: Faster material handling allows crews to take on more work.

- Reduce Manual Labor: Automation decreases the need for hands-on unloading.

- Enhance Jobsite Safety: Reduces the need for crews to climb in and out of the trailer or scoop/pitch material into wheelbarrows, helping prevent strains and related injuries.

Frequently Asked Questions (FAQ)

What kind of maintenance does a live floor trailer require?

Live floor trailers require regular maintenance on their hydraulic systems and conveyor components, similar to other hydraulic machinery. This is a key difference from the simpler maintenance of a utility trailer.

Can a live floor trailer handle wet or heavy materials?

Yes, high-quality live floor trailers are designed to handle a wide range of materials, including wet mulch, soil, and heavy aggregates like gravel.

Is a live floor trailer difficult to operate?

While more complex than a basic utility trailer, modern live floor systems are designed with user-friendly controls, allowing operators to manage unloading speed and direction with minimal training.

The Smart Investment: Driving Profitability with the Right Trailer

While dump and utility trailers have their place, the choice is clear for landscaping businesses aiming to maximize productivity and safety. The live floor trailer’s controlled, non-tilting system makes it the superior strategic asset. By reducing labor costs and minimizing jobsite risks, an investment in a high-quality live floor trailer like the Mulch Mule will pay dividends for years to come.

For businesses committed to leading the market, the next step is to witness the difference this equipment can make for your crew and your bottom line. Schedule your live demonstration today to see firsthand how the Mulch Mule delivers unparalleled efficiency on a real job site.