Live floor trailer systems have redefined material handling in landscaping by offering a controlled and efficient alternative to traditional dump trailers. Instead of tipping to unload, these systems use moving slats or belts to steadily transport bulk materials like mulch, soil, and gravel. This technology reduces labor costs, improves jobsite safety, and enhances operational precision—critical advantages for busy landscaping professionals.

In this article, we explore what live floor trailer systems are, highlight their key components, explain their step-by-step operation, and share practical tips for optimizing material flow and safety on the jobsite.

What Is a Live Floor Trailer System and Why Does It Matter?

A live floor trailer system unloads materials by “walking” them out using a hydraulically powered moving floor—most commonly reciprocating slats or belt-over-chain rolling panels—rather than relying on the risks associated with tilting. This method allows for more precise placement of materials even in confined spaces or on uneven terrain. Users experience improved stability and control, making these systems especially valuable for landscapes that demand accuracy and safety.

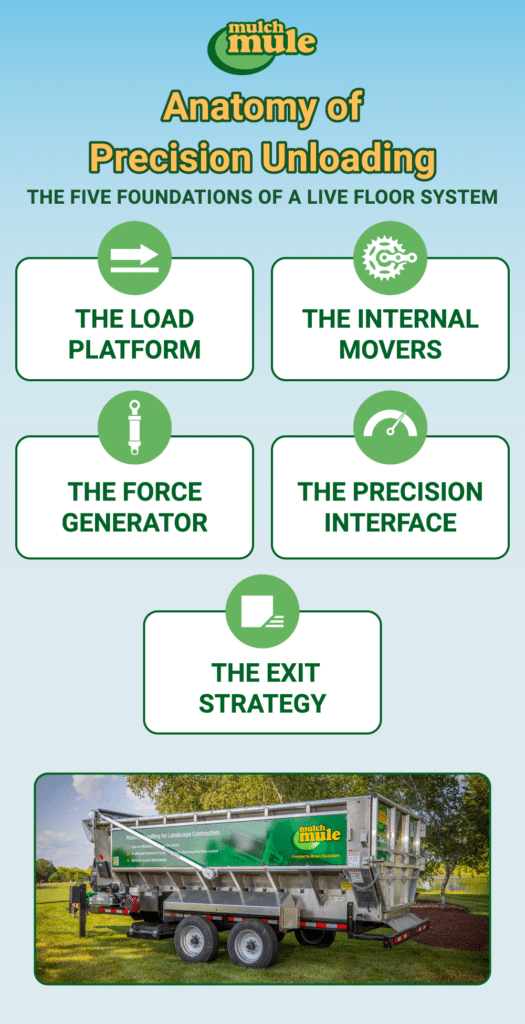

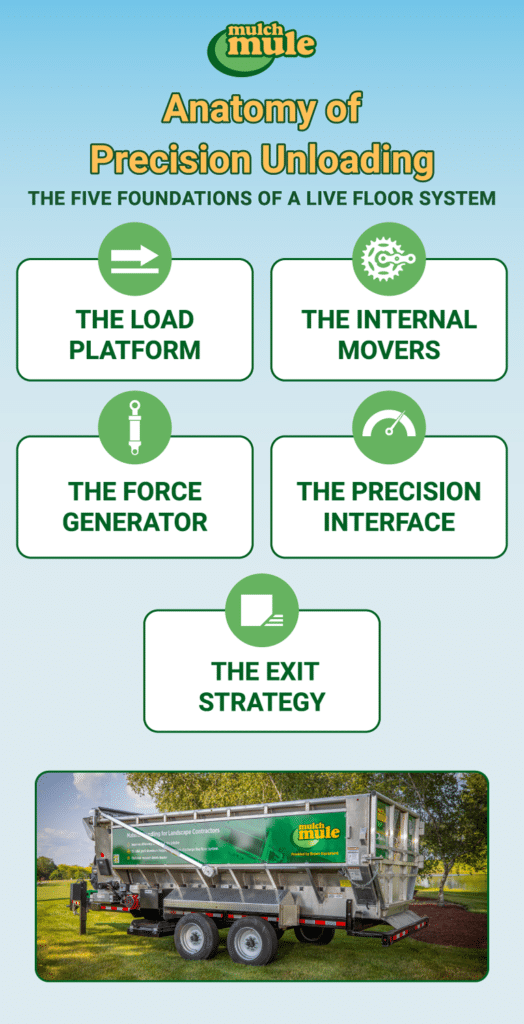

The Core Parts of a Live Floor System

A live floor trailer is built around a simple idea: use hydraulic power to move the trailer floor so material is conveyed out in a controlled stream. The consistency you get on the jobsite—whether you’re metering mulch into wheelbarrows or building a clean stockpile—comes from a handful of core components working together.

Moving Floor/Slats or Belt-Over-Chain Floor

This is the “conveyor surface” your material rides on.

- Slat-style floors use multiple aluminum or steel slats that move in a timed sequence to “walk” the load toward the discharge opening. The alternating motion helps reduce bridging and keeps material moving steadily.

- Belt-over-chain floors use a continuous belt supported and pulled by chains. This style can be especially helpful for protecting the floor surface and moving certain materials smoothly.

In both designs, the moving floor is what enables flat, non-tipping unloading—a big safety advantage on uneven ground or under trees/overhead obstacles.

Chains/Sprockets/Rollers: The Traction That Actually Pulls Material

If the floor is the “surface,” the chain-and-drive components are the traction system underneath.

- Chains provide the pulling force that moves the slats/belt.

- Sprockets engage the chains and transfer torque from the drive system.

- Rollers/guides help keep everything aligned, reduce drag, and support smooth movement across the trailer length.

This is the hardware that turns hydraulic power into forward motion—especially important when you’re moving dense loads like wet soil, compost, or aggregate that would overwhelm lighter-duty unloading setups.

Drive Power: Hydraulic Drive or Engine-Driven Hydraulic Power Pack

Live floor trailers are powered by hydraulics, and they generally get hydraulic power in one of two ways:

- Hydraulic power from the truck/tractor is common when the towing vehicle is set up with the right hydraulic capability).

- A self-contained, engine-driven hydraulic power pack on the trailer, which lets the trailer operate more independently of the tow vehicle.

Either way, the drive system supplies the force needed to move the floor under load, and it’s what allows live floors to handle a wider range of material types than gravity-based dumping.

Controls: Speed, Forward/Reverse, Remote Options

Controls are where live floors really earn their reputation for precision.

Operators can typically:

- Start/stop the floor instantly

- Adjust speed (slow for metering into bins or wheelbarrows; faster for bulk discharge)

- Switch forward/reverse to correct flow, clear bridging, or fine-tune placement

Many setups also offer remote control options, which can improve convenience and jobsite safety by letting the operator run the discharge while standing where visibility is best.

Discharge Area: Rear Discharge vs. Curb-Side Discharge Options

The discharge configuration determines where and how the material exits the trailer.

- Rear discharge is the most common: material “walks” out the back in a controlled stream for stockpiles, hopper feeding, or spreading.

- Curb-side discharge (available on certain configurations) is designed primarily for filling wheelbarrows directly from the side of the trailer, allowing crews to load and move materials without working behind the unit or stepping into the roadway.

Choosing the right discharge style affects efficiency, cleanup, and how precisely you can place mulch, soil, gravel, or compost on real-world sites.

Step-by-Step: What Happens From Loading to Unloading

Live floor trailers unload by conveying material out in a controlled stream—so you can place mulch, soil, compost, or aggregate without tipping the trailer.

Step 1 — Loading the Hopper: How the Floor “Receives” Material

During loading, the moving floor acts like a normal trailer floor—it supports the load until unloading starts. For best results, load evenly front-to-back and side-to-side and avoid concentrating heavy clumps in one spot.

Step 2 — Transport: What Keeps the Load Stable vs. Tipping Systems

In transit, the load stays low and level. Unlike dump trailers, a live floor doesn’t need to raise the body to unload, which helps reduce instability risk and makes it practical for tighter or uneven sites.

Step 3 — Staging at the Jobsite: Positioning for Precision and Safety

Position the trailer on firm ground and line up the discharge so material lands where you want it—stockpile, bin, or work zone. Keep people clear of the discharge path and maintain good visibility before you engage the floor.

Step 4 — Controlled Discharge: Slow-Feed vs. Quick Empty

Start the hydraulics and choose a discharge rate:

- Slow-Feed: for wheelbarrows, bins, or tight placement

- Quick-Empty: for fast stockpiles and turnaround

Step 5 — Stop, Reverse, Fine-Tune: Why Reverse Exists

Stop and reverse let you manage real-world flow—pause discharge, reduce surging, break minor bridging, or fine-tune where material lands without extra hand work.

Step 6 — Cleanout Basics: What “Empty” Really Means

“Empty” means more than “looks empty.” Run the floor until discharge stops and the floor is clearly exposed, then check for packed corners or buildup near the discharge opening—especially after wet or sticky materials.

Optimizing Material Flow and Precision

Live floor systems excel not only in unloading material but also in ensuring it is delivered precisely:

Adjusting Discharge Speed

Operators can adjust speed settings to match the specific requirements of the task. A slower pace is ideal for precise applications, while faster speeds are beneficial for creating stockpiles quickly.

Directional Control

The ability to move materials forward and reverse allows for corrective adjustments without interrupting work. This flexibility prevents waste and minimizes cleanup time.

Addressing Material Flow Challenges

Different landscaping materials can behave unpredictably during unloading. Here are common challenges and practical solutions:

Mulch

Mulch’s lightweight, stringy fibers may form clumps during discharge. To overcome this, break up any large clumps before loading and use intermittent reversing to promote even distribution. Trailers like the Mulch Mule also include a dedicated “cleanout” function that runs the discharge chute and conditioners without pulling more material forward—helping clear residual buildup without disrupting the next load.

Soil and Compost

Wet soil and compost tend to clump together. Adjusting the discharge speed to a slower rate can help manage these heavier loads, while regular cleaning of the system prevents residue buildup.

Aggregates

Heavier materials like gravel demand evenly distributed loads to avoid stressing the system. Consistent operator best practices—such as even loading, regular inspections, and periodic reversing—help maintain smooth material flow and extend the lifespan of the equipment.

Safety Tips for Operating Live Floor Trailers

Although live floor systems offer enhanced safety features compared to dump trailers, proper operational practices remain essential:

Maintain Safe Operator Positioning

Operators should keep a safe distance from moving parts during unloading. Staying clear of the trailer while the floor is live helps ensure no injuries occur.

Establish Clear Jobsite Zones

Designate unloading areas with physical markers to keep other workers and bystanders away from active machinery. Clear communication about these zones reduces the risk of injury.

Adapt to Terrain and Confined Spaces

Even though live floor systems work effectively on uneven or tight spaces, a quick site assessment for obstacles—such as soft ground or overhead hazards—is always necessary.

Perform Routine Safety Checks

Regular inspections of tires, suspension, and hydraulic components ensure the equipment remains in optimal condition. Pre-operational safety checks help identify and address potential issues before they become hazards.

Comparing Live Floor Trailers with Other Systems

Understanding the advantages of live floor trailers relative to alternative unloading systems helps in making informed decisions:

Versus Dump Trailers

Dump trailers require tilting, which can lead to instability and spillage on uneven or confined sites. In contrast, live floor systems offer smooth, flat unloading that minimizes hazards and allows operation in restricted spaces. This comparison highlights why many choose live floor technology over traditional dump trailers.

Versus Conveyor-Only Systems

While conveyor-only systems can be effective for handling lightweight materials in controlled settings, they generally lack the versatility of live floors. Live floor trailers manage a broader range of materials—including heavy aggregates and moisture-prone loads—with adjustable controls that enhance operational precision.

For landscaping professionals managing diverse projects, the flexibility and precision of live floor trailer systems often translate into significant time savings and improved safety—factors that can justify the initial investment.

FAQs About Live Floor Systems

Below are brief answers to common questions that landscaping professionals ask about live floor systems:

Are “Walking Floor” and “Live Floor” Systems the Same?

Yes. Both terms describe a trailer that unloads using a hydraulically powered moving floor (slats or belt-over-chain) instead of tipping like a dump trailer.

Can Live Floor Systems Handle Wet or Sticky Materials?

Absolutely. Wet mulch, compost, and damp soil can be unloaded effectively—especially when you load evenly, run appropriate discharge speeds, and keep the floor/discharge area clean to reduce buildup.

What Materials Can a Live Floor Trailer Unload for Landscaping Jobs?

Most bulk landscaping materials, including mulch, topsoil, compost, sand, and aggregates like gravel. The key is matching operating technique to the material (even loading for aggregates, slower metering for clumpy/wet loads).

Do I Need a Special Truck to Run a Live Floor Trailer?

Not always. Some live floor trailers, such as the Mulch Mule trailer, use a self-contained, engine-driven hydraulic power pack on the trailer. The best choice depends on your fleet setup and how independently you want the trailer to operate.

How Do I Prevent Bridging, Surging, or Uneven Flow During Unloading?

Routine, preventative maintenance is the difference-maker: regular inspections of hydraulic lines/fittings, checking chain/roller alignment and wear, keeping sprockets/drive components in good condition, and cleaning out after wet or sticky materials to prevent hardened buildup near the discharge end. The Mulch Mule simplifies this last step with a dedicated “cleanout” function that clears residual material through the discharge chute without needing to open the rear door and run reverse—a process that can be messy and time-consuming. Reverse remains available for addressing jams if needed.

How Much Maintenance Do Live Floor Systems Typically Require?

Routine, preventative maintenance is the difference-maker: regular inspections of hydraulic lines/fittings, checking chain/roller alignment and wear, keeping sprockets/drive components in good condition, and cleaning out after wet or sticky materials to prevent hardened buildup near the discharge end.

Business Benefits of Live Floor Systems

Investing in live floor technology delivers tangible benefits:

- Lower labor costs through automation.

- Enhanced safety by eliminating the need for tilting.

- Increased job capacity with faster, more accurate unloading.

- Improved productivity with precise control over material placement—whether you work with mulch, soil, or aggregates.

- Elevated crew morale by reducing physical strain and risk of injury.

These benefits contribute to a stronger bottom line and a more competitive operation in today’s demanding landscaping market.

Revolutionizing Landscaping Efficiency with Live Floor Trailers

Live floor trailer systems are transforming material handling in the landscaping industry by offering precise control, improved safety, and enhanced efficiency. From consistent material flow to flexible discharge options, these systems streamline operations in a way that traditional dump trailers cannot match. Whether you work with mulch, soil, or aggregates, a live floor system can reduce labor costs and boost productivity while safeguarding your team’s well-being.

For landscaping businesses aiming to optimize their workflows and improve project outcomes, exploring live floor technology is a smart investment. Discover how innovative systems like those offered by Mulch Mule can revolutionize your operations—contact us today to schedule a demonstration and experience the benefits firsthand.

Watch the video below to learn more about how Mulch Mule provides invaluable features for landscaping businesses.