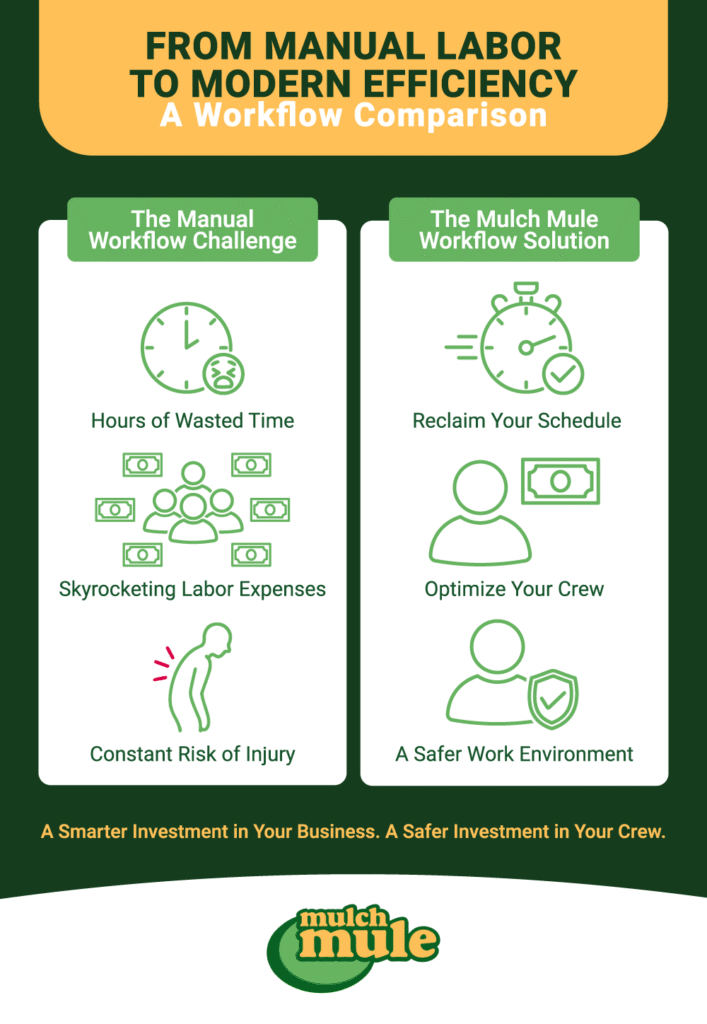

The landscaping industry is undergoing a transformation with technology that optimizes project management, material handling, and team operations. While traditional methods often require time-consuming manual labor, modern equipment provides solutions that reduce inefficiencies, cut costs, and improve safety.

These innovations not only save valuable hours but also help businesses scale operations and remain competitive in an ever-evolving market. In this article, we explore how landscaping technology is reshaping operations—from overcoming common challenges to improving workflow efficiency and workforce safety—with a focus on the Mulch Mule, an advanced material-handling trailer designed for today’s landscaping demands.

Challenges Faced by Landscaping Professionals

Landscaping businesses confront several obstacles that can delay projects and reduce profitability. Identifying and addressing these challenges is crucial for maintaining a competitive edge.

Rising Labor Costs

Manually shoveling and handling bulk materials often requires large crews, leading to higher labor and insurance expenses. This repetitive, physically demanding work drains resources and causes crew fatigue. As wages and insurance premiums continue to climb, controlling labor costs has become essential to business longevity. Strategies for mitigating these expenses are covered in rising labor costs.

Safety Risks

When staff repeatedly lift and shovel heavy materials, they’re prone to back strains and other injuries. Such incidents can lead to lost workdays, higher workers’ compensation claims, and compromised morale. Adopting a robust safety culture is therefore paramount. Methods for reducing risks can be found in safety risks.

Tight Deadlines

Clients increasingly demand faster job completion. Relying on manual loading and transport methods can cause delays, damaging a company’s reputation and hindering repeat business. Balancing workload and scheduling is crucial for success, as explained in tips for meeting tight deadlines.

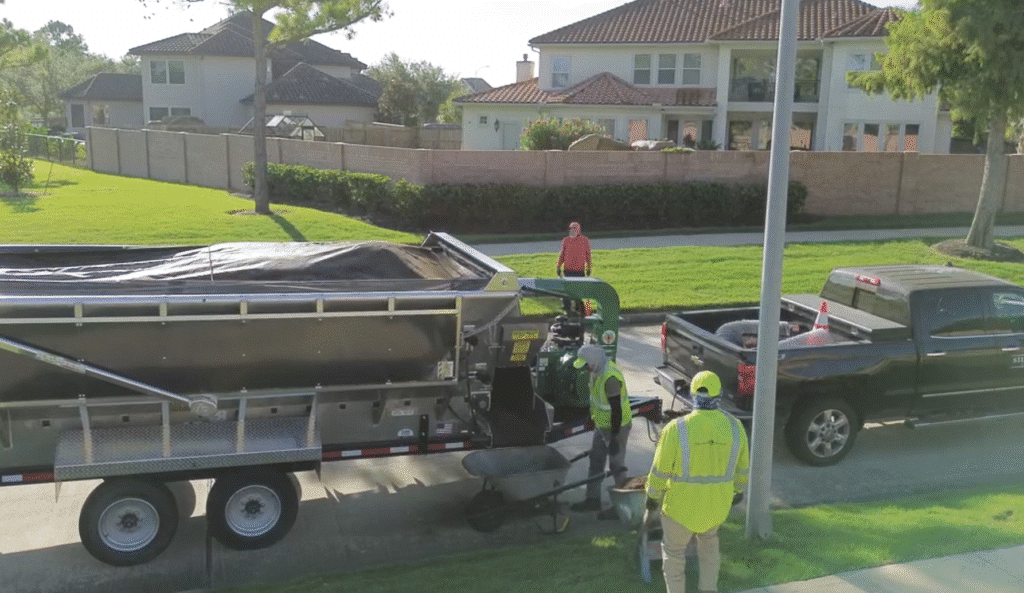

The Solution: The Mulch Mule

The Mulch Mule is an innovative solution engineered to simplify the transportation and distribution of mulch, soil, leaves, debris, stone, and aggregate. Designed for outstanding productivity and safety, this versatile trailer directly addresses many of the industry’s most persistent challenges and transforms landscaping operations from the ground up.

Key Features

- 15 Cubic Yard Hopper: The Mulch Mule boasts a large, aluminum hopper capable of holding 15 cubic yards of material. Its advanced live floor system is engineered to discharge materials rapidly, drastically reducing the downtime typically required for manual unloads.

- Live Floor System: Instead of relying on manual labor to clear out each load, the moving floor swiftly pushes material off the tray, ensuring tasks are completed quickly and cleanly.

- Handheld Remote Control: Operators can unload materials with precision, ensuring efficient placement with minimal effort.

- Conveyor (Optional): This convenient attachment enhances functionality by directing materials to hard-to-reach areas along sidewalks, gardens, or tight spaces. Additionally, for specialized tasks, businesses can explore a variety of Mulch Mule Attachments and Upgrades designed to maximize productivity and efficiency.

- Vacuum Debris Loader (Optional): Perfect for fall cleanup or removing excess leaves and debris.

With these features, the Mulch Mule helps businesses scale operations, reduce the risk of back injuries, and boost crew morale by automating some of the most laborious tasks in landscaping. These features translate directly into three core benefits that solve the industry’s biggest challenges.

Benefit 1: Reclaim Your Time & Meet Deadlines

One of the standout advantages of the Mulch Mule is its capacity to expedite vital processes on any job site. The trailer offers a significant leap in productivity compared to manual methods. This is a game changer for meeting tight client deadlines.

- Rapid Hopper Discharge: Thanks to its innovative live floor system, the trailer unloads its entire contents very quickly, eliminating the hours crews would spend shoveling material out of a standard trailer.

- Wheelbarrow Filling: The system is precisely designed to fill a wheelbarrow quickly, freeing up valuable labor time so teams can focus on planting, trimming, and other skilled tasks instead of waiting around.

By substantially reducing manual handling times, landscaping companies gain more opportunities to complete projects faster, serve additional clients, and build a reputation for prompt, efficient service.

Benefit 2: Protect Your Crew & Reduce Risk

In addition to improved efficiency, modern landscaping equipment significantly enhances worksite safety by design.

- Reducing Physical Strain: Automated systems like the Mulch Mule’s live floor minimize the need to repeatedly shovel and lift heavy materials. With fewer hours spent on strenuous manual labor, the risk of sprains and back injuries is dramatically lowered, leading to fewer workers’ compensation claims and improved overall team morale.

- Cleaner, Safer Work Environments: A cleaner site is a safer site. By automating both loading and unloading processes, on-site dust and debris are controlled and reduced. This organized workspace helps to minimize slip-and-fall incidents, allowing teams to maintain high safety standards consistently.

Benefit 3: Boost Your Bottom Line

Investing in modern landscaping equipment is not merely an operational upgrade; it is a strategic initiative that directly and positively impacts a company’s bottom line.

- Lower Labor Costs: By automating labor-intensive tasks such as manual shoveling, the Mulch Mule allows companies to reassign human resources to higher-value operations. This immediate reduction in labor expenses is complemented by a more efficient deployment of existing staff on more profitable tasks.

- Reduced Injury-Related Expenses: Automating heavy lifting and repetitive motions significantly reduces workplace injuries, thereby cutting down on medical and insurance-related expenses while also minimizing the costly impact of unplanned labor shortages.

- Faster Project Completion: Shorter job turnaround times often lead to higher customer satisfaction and increased project capacity. A fast, automated discharge process means that daily tasks are completed promptly, creating room for additional revenue-generating projects in a given period.

- Increased Equipment Longevity: Durability is a key aspect of the Mulch Mule’s design. From its robust aluminum hopper to its range of optional attachments, every component is built for long-term performance under demanding conditions, ensuring a consistent and lasting return on your investment.

Year-Round Applications of the Mulch Mule

Modern landscaping challenges aren’t limited to summertime endeavors. The Mulch Mule is designed to deliver efficiency throughout the year, meeting varied project demands in every season.

Spring and Summer

During the busy landscape season, companies face high demands for mulch application, soil placement, and yard enhancements. The Mulch Mule’s generous capacity and rapid discharge capabilities enable crews to move seamlessly between sites, addressing high client demand without sacrificing quality.

Fall

Autumn cleanup can be challenging due to the rapid accumulation of leaves, small branches, and other debris. An optional vacuum debris loader collects and disposes of organic waste efficiently, significantly cutting down on the time required for raking and manual hauling.

Winter

In colder months, the Mulch Mule can effectively handle sand or other lightweight aggregates. By repurposing the same equipment across all seasons, businesses benefit from a strong return on investment while keeping crews actively engaged year-round.

Ideal Use Cases: Where the Mulch Mule Shines

The Mulch Mule is a versatile workhorse, but it delivers maximum impact on specific types of jobs where efficiency is paramount:

- Large-Scale Commercial and Residential Mulching: For properties requiring 10+ cubic yards of material, the large hopper and rapid unload system eliminate hours of manual labor, allowing crews to complete large jobs in a fraction of the time.

- Municipal and HOA Leaf Cleanup: When equipped with the optional vacuum debris loader, it becomes a fall cleanup powerhouse, quickly clearing large common areas, parks, and streetscapes without the need for extensive raking and bagging.

- Playground and Pathway Installation: When laying engineered wood fiber, stone, or aggregate, the optional Curbside Discharge Conveyor allows for precise material placement in hard-to-reach areas, reducing the need for wheelbarrowing over delicate turf or long distances.

- Winter Material Spreading: In colder climates, the Mule is perfect for efficiently handling and distributing large volumes of sand for commercial properties and parking lots.

A Balanced View: Potential Drawbacks and Considerations

Despite its significant advantages, adopting advanced landscaping technology requires a balanced evaluation of potential challenges:

- Initial Investment: Although the Mulch Mule helps reduce labor inputs, it does require an upfront capital investment. For smaller or newer landscaping businesses, this initial cost may be a consideration. Detailed budget analysis and exploring financing options can help mitigate this concern.

- Training Requirements: While user-friendly, the Mulch Mule does require proper training to maximize its benefits. Staff must become familiar with the live floor system, handheld remote controls, and optional attachments. Although training sessions are typically brief, incorporating them into the schedule is essential for effective use.

- Maintenance and Repairs: As with any sophisticated equipment, regular maintenance is necessary to ensure reliability. Scheduled inspections, cleaning, and parts replacement can prevent unexpected downtime.

- Space Constraints and Storage: The large capacity of the Mulch Mule means that adequate storage space is required. Ensuring that your operation has sufficient room for maneuvering and storing the equipment is an important part of the planning process.

By weighing these considerations against the substantial benefits, landscaping professionals can determine how well this state-of-the-art trailer aligns with their business models. Effective planning and regular preventative maintenance can turn these challenges into manageable aspects of long-term operational success.

The Future is Here: Adopting a Tech-Forward Culture

Implementing advanced tools like the Mulch Mule is the first step toward modernizing your operations. The next is cultivating an organizational culture that values innovation and continuous improvement, positioning your business to thrive as the industry evolves.

This forward-thinking culture also increasingly includes environmental responsibility. Embracing eco-friendly practices and equipment not only addresses growing client demand for sustainability but can also lead to significant cost savings through reduced waste and more efficient resource use. Innovations in energy efficiency and sustainable designs, like those found in modern equipment, are key drivers of future profitability and corporate stewardship.

Embracing this future requires more than just purchasing high-tech equipment; it demands a shift in mindset.

- Invest in Comprehensive Training: When employees understand the full capabilities of new equipment they become proactive advocates for fully utilizing its functions. A well-trained team is an efficient team.

- Encourage a Feedback Loop: Frontline staff, familiar with the nuances of daily operations, can offer invaluable insights on optimizing processes, scheduling, or equipment use. Incorporating their feedback not only enhances operational efficiency but also fosters a sense of shared ownership and success.

- Adapt Workflows Intentionally: To truly capitalize on modern equipment, old workflows must be updated. Revising procedural manuals, planning tools, and internal communications ensures that teams remain aligned with new, more efficient practices.

Ultimately, this synergy between employee expertise and advanced technology is what builds a resilient, competitive, and future-ready landscaping organization.

Build a More Efficient Future for Your Business with Landscaping Technology

The future of landscaping is here, driven by technology that enhances efficiency, safety, and profitability. Investing in advanced equipment like the Mulch Mule is a strategic decision to leave behind the limitations of manual labor and embrace a smarter, more productive way of operating. From its rapid unloading system to its year-round versatility, the Mulch Mule is designed to give you a definitive competitive edge.

The best way to see how this technology can reshape your business is to witness it yourself. Get a quote for the Mulch Mule trailer today and take a decisive step toward increased efficiency and sustained success.