In today’s commercial landscaping industry, efficient material handling is a game-changer. Landscape professionals—whether managing commercial properties or smaller lawn care operations—face constant challenges with rising labor costs, project delays, and safety risks. Automation offers a solution to streamline operations, reduce costs, and protect workers. However, determining whether your business is ready for automated material handling requires a clear, focused evaluation of your current processes and needs.

This article provides a concise guide for landscaping and grounds management professionals to assess their “automation readiness.” We explore common challenges resulting from manual material handling, outline key indicators that suggest automation might be beneficial, and offer practical steps to prepare for a smooth transition. The goal is to help you evaluate if now is the right time to invest in automated solutions like the Mulch Mule trailer, all while acknowledging that outcomes depend on proper implementation and the specific context of your operations. Recognizing the value of forward-thinking strategies can position your business at the forefront of an evolving industry, ensuring sustained growth and resilience in competitive markets.

The Challenges of Manual Material Handling

Manual handling of bulk materials such as mulch, soil, and debris has long been the standard for many landscaping businesses. Yet, this approach often leads to a number of persistent challenges:

Labor Dependence and Rising Costs

Relying on manual labor for repetitive tasks like loading, unloading, and distributing materials is both time-consuming and costly. Labor shortages, increased wages, and overtime expenses can quickly erode profit margins and restrict growth.

Safety and Worker Fatigue

Repetitive tasks increase the risk of injuries such as back strain or musculoskeletal disorders. These injuries drive up workers’ compensation claims and lower employee morale. Over time, the physical demands of manual handling can also result in higher turnover and reduced productivity.

Inefficiency and Project Delays

Manual methods tend to slow down project timelines. Processes like hand-loading wheelbarrows or distributing materials create bottlenecks, resulting in delays that can frustrate clients and lead to lost business opportunities.

Limited Scalability

When manual handling dominates, the capacity to take on larger or more complex projects is limited. This constraint hampers business growth, especially as client expectations shift toward faster, more reliable service.

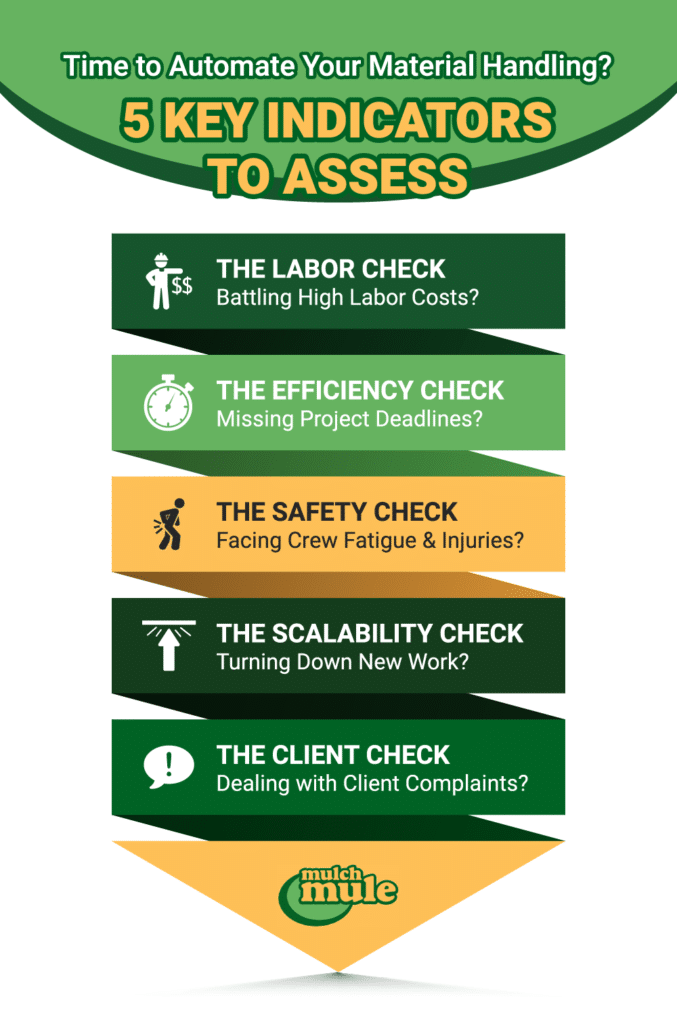

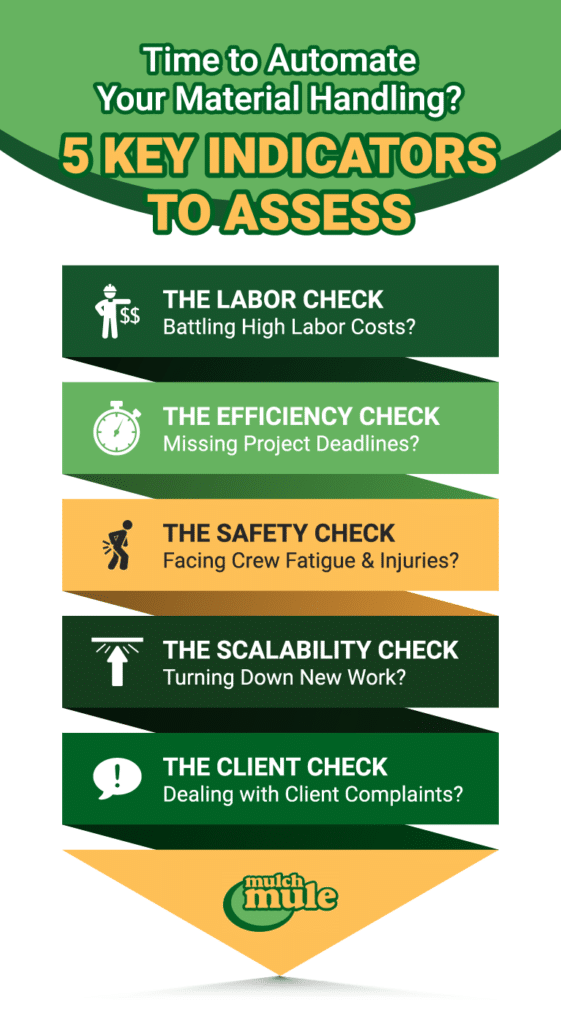

Signs Your Business Is Ready for Automation: A Self-Assessment Checklist

Transitioning to automation can help address the challenges of manual material handling—but how do you know if the time is right for your business? Use the indicators and questions below as a quick self-assessment.

Operational Signs to Watch For

Increasing Workload and Project Complexity

If manual methods are no longer keeping pace with growing demands, it may be time to explore equipment capable of handling large quantities of material. As project scopes expand, automated solutions can help you maintain efficiency and consistency.

Persistent Labor Shortages

Ongoing difficulties in hiring and retaining skilled labor—as well as high turnover rates—suggest that reducing dependency on manual processes could stabilize operations and control costs.

Repeated Safety Incidents

If workplace injuries, near-misses, or fatigue are recurring issues, the physical strain of manual tasks may be unsustainable. Automation can assume many labor-intensive duties, contributing to a safer work environment and improving employee morale. For additional information on prevention strategies, consult relevant OSHA guidelines.

Client Demands for Faster Service

Many clients now expect rapid turnarounds, and manual processes often fall short. Automation may enhance service efficiency, boosting customer satisfaction and helping your business stand out.

Quick Self-Assessment Checklist

Review the questions below. If you find yourself answering “yes” to several of them, your business may be ready to benefit from automated material handling:

- Are rising labor costs and overtime expenses significantly affecting profitability?

- Do manual loading and unloading processes frequently delay project timelines?

- Have recurring safety issues led to injuries or diminished morale?

- Are you rejecting larger projects due to capacity constraints?

- Are client complaints about slow service or missed deadlines common?

If these challenges sound familiar, it may be the right time to explore how automation can support your operations and long-term growth.

The Business Benefits of Automation

Adopting automated material handling solutions can transform your landscaping business in several important ways:

- Lower Labor Costs: Automation reduces the need for repetitive manual labor. This can decrease overtime expenses and free up resources for more value-added tasks.

- Greater Productivity and Profitability: By accelerating material handling, projects can be completed more swiftly, enabling you to take on additional work. Integrating automated material handling systems optimizes these benefits.

- Improved Worker Safety: Automated equipment helps reduce the physical strain on workers, lowering the risk of injuries while enhancing overall morale.

- Year-Round Versatility: Advanced equipment can handle everything from mulching in the spring to debris clearing in the fall, maintaining consistent efficiency across seasons.

- Competitive Market Advantage: Streamlined processes improve project completion times and can raise customer satisfaction, providing a valuable differentiator in the landscaping market.

Addressing Common Concerns About Automation

When contemplating automation, several concerns may arise. Addressing these can help you make an informed decision:

Concern #1: Our Business Isn’t Big Enough

Automation isn’t solely for large enterprises. Even small operations can experience efficiency improvements from automated solutions, enabling them to handle bigger projects without a corresponding increase in labor costs.

Concern #2: The Equipment Is Too Expensive

While the initial investment can be significant, automated solutions often help reduce labor, overtime, and injury-related costs over time, provided they are implemented and maintained properly. Actual results vary based on the organization’s unique needs and management practices.

Concern #3: We’ve Always Done It Manually

Although manual methods have worked in the past, the landscaping industry is evolving, and client expectations demand faster, more efficient processes. Automation is intended to enhance existing methods rather than replace valuable expertise.

Concern #4: Automation Will Replace My Team

Automation typically shifts the nature of work, reducing the most repetitive and physically demanding tasks. In many cases, it enables employees to move into roles involving oversight, design, or customer service. However, the overall impact on staffing depends on how each business implements new technologies.

Concern #5: The Technology Is Too Complex

Modern automation tools often come with user-friendly interfaces. Basic functions can be learned quickly, while more advanced features may require additional training. Manufacturer support and onboarding programs help ensure a smooth transition.

How to Prepare for Your Transition to Automation

A successful transition to automation demands careful planning. Below are some strategies to integrate new equipment and processes into your operations:

- Research and Select Appropriate Equipment: Investigate various options—such as live floor trailers or curb-side discharge systems—that align with your material handling requirements.

- Identify Workflow Bottlenecks: Pinpoint inefficiencies in your current operations. Prioritize areas where automation will have the greatest impact on speed and reduced strain on your team.

- Engage and Train Your Team: Educate employees early, sharing how automation can simplify tasks and improve safety. Provide thorough training on equipment functions, especially if more advanced features are introduced over time.

- Develop a Financial Strategy: Weigh the potential long-term savings from reduced labor expenses and fewer injuries against initial costs. Leasing or financing options can also make the upfront investment more manageable.

- Set Realistic Expectations: Allow time for teams to adapt to new systems. Track progress with concrete milestones to measure gains in efficiency and productivity.

How Mulch Mule Supports Your Automation Journey

Mulch Mule offers solutions customized for the landscaping industry. Their equipment is specifically designed to automate bulk material handling while enhancing safety and productivity:

- Efficient Material Handling Systems: Employing advanced live floor systems allows for rapid unloading of large quantities of materials, reducing unloading time per job and minimizing downtime between sites.

- Precise Material Distribution: Features like curb-side discharge systems help place materials where they’re needed, easing the physical burden on your crew and boosting efficiency.

- Versatile, Year-Round Operation: The ability to handle mulch, soil, leaves, and debris ensures consistent productivity throughout the year.

- Focus on Worker Safety: By shifting workers away from repetitive, strenuous tasks, Mulch Mule helps create a safer workplace, lowering the risk of strain-related injuries and improving crew morale.

- Expert Support and Demonstrations: Mulch Mule’s ambassador program offers practical, hands-on support and live demonstrations, shortening your learning curve and helping you see a return on investment sooner.

Profitability, efficiency, simplicity, and employee morale are just some of the benefits of using Mulch Mule for mulch, soil, gravel and then vacuuming leaves in the fall. Andrew and Anthony Gage are happy customers of two Mulch Mules! Click on the video below to hear what they have to say about their experience with the Mulch Mule.

Measuring the Impact of Automation

After introducing automated systems, continual evaluations of performance are essential. Track key performance indicators, such as labor hours saved, faster project completion times, and a decline in worker injuries. Periodic assessments help confirm that your chosen approaches remain cost-effective and aligned with industry trends. Monitoring your benchmarks also allows you to identify any gaps and make timely adjustments for ongoing efficiency.

Is Your Landscaping Business Ready for Automation?

Assessing your readiness involves examining labor costs, project delays, safety issues, and growth limitations. If your company faces these concerns, automation could offer a path to heightened efficiency, increased profitability, and a safer work environment. Taking the time to properly plan for automation—through collaboration, clear training, and realistic financial expectations—can form the backbone of a successful transition.

As the landscaping industry continues to evolve, now is the time to evaluate your operations, make informed investments, and position your company for future competitiveness. By taking a thoughtful, strategic approach, you can ensure that automation enhances your team’s capabilities without compromising quality or safety. Schedule a live demonstration of the Mulch Mule trailer to discover how it can help you maximize efficiency in your landscaping projects through smart automation.