Efficient landscaping operations require organization, productivity, and safety. In this fast-paced industry, adopting proven strategies that streamline workflows is essential. One such strategy is the 5S methodology—a lean management practice originally designed for manufacturing that has proven effective in landscaping. Tools like the Mulch Mule help improve efficiency by automating material handling and reducing manual labor.

This guide explores the fundamentals of 5S landscaping productivity, outlines each step of the methodology, and demonstrates how integrating advanced equipment can drive efficiency and safety across your operations.

What is the 5S Methodology?

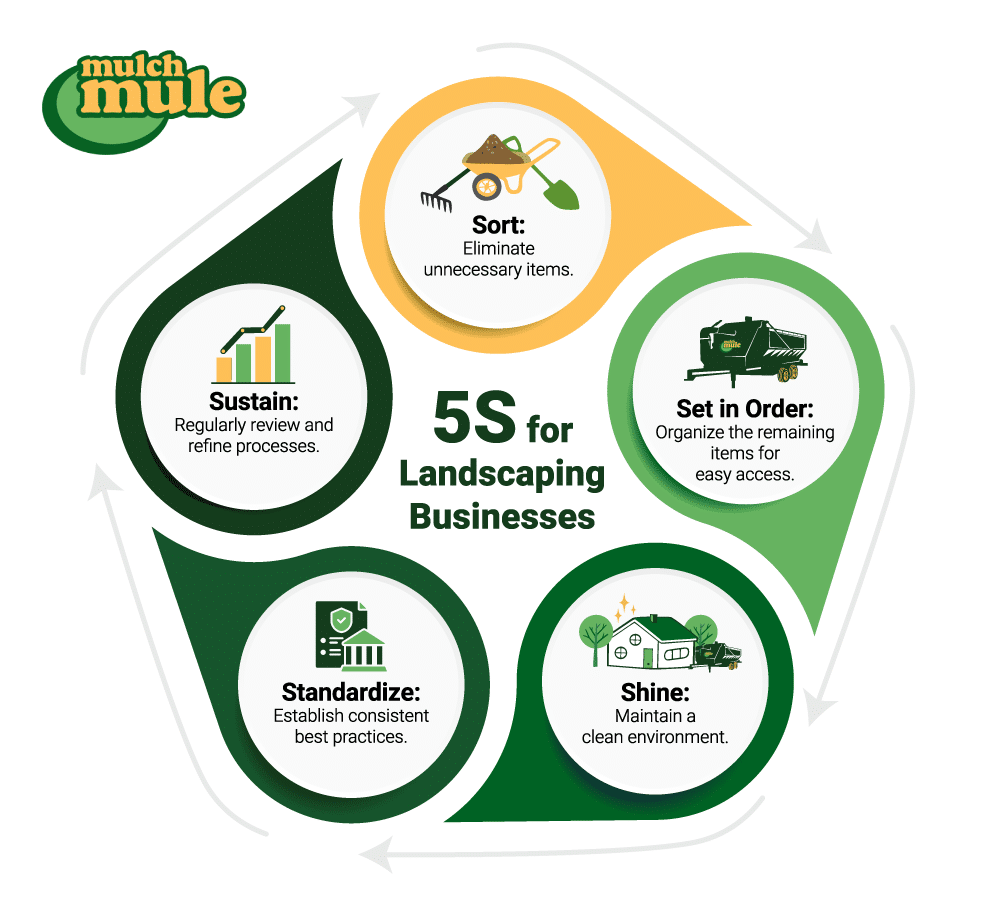

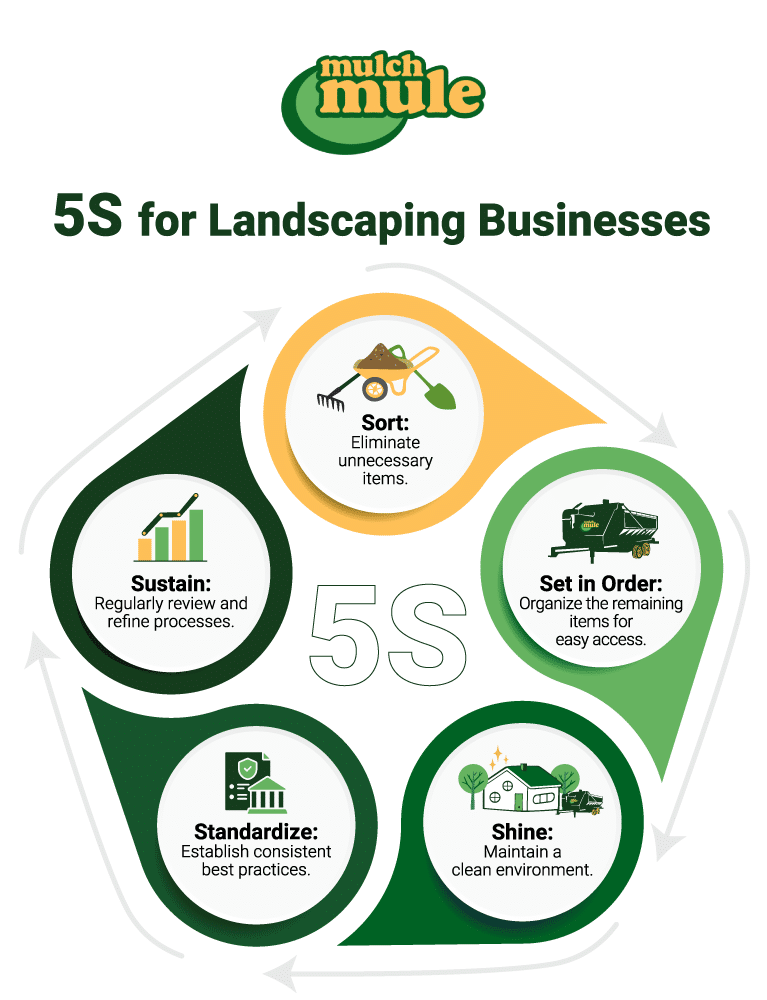

The 5S methodology is a systematic approach to workplace organization that emphasizes continuous improvement. It comprises five key principles:

By adopting these principles, landscaping businesses can reduce clutter, prevent equipment downtime, and improve overall efficiency. The framework is practical enough to be integrated into daily operations, whether it’s organizing tools for mulch application or setting up efficient storage for seasonal equipment.

How Can the 5S Methodology Be Applied in Landscaping?

Landscapers face demanding project deadlines, limited labor resources, and diverse equipment needs in dynamic outdoor environments. The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to organizing workspaces, reducing waste, and boosting productivity. When applied to landscaping, 5S transforms chaotic job sites into efficient, well-organized work areas that minimize downtime and enhance safety.

Many industry experts note that adopting lean management principles can lead to significant improvements in workforce efficiency. Integrating equipment with these practices can simplify material distribution and debris collection, allowing teams to focus on delivering high-quality work.

Benefits of 5S for Landscaping Businesses

Implementing 5S in landscaping delivers several tangible benefits:

Boosted Efficiency

Organized tools and systematic workflows reduce the time spent searching for equipment. With clearly designated areas for frequently used items, crews can transition smoothly between tasks, leading to faster project completion.

Reduced Labor Costs

Labor expenses are a significant factor in landscaping budgets, making the efficiencies gained through 5S even more valuable. When tools and materials are well organized, workers can focus on high-value tasks rather than manual, time-consuming chores.

Improved Safety and Morale

A clean and orderly worksite minimizes hazards such as tripping over misplaced tools or operating poorly maintained equipment. In addition to reducing injury risks, a tidy work environment helps boost team morale.

Material Management and Cost Savings

Standardized inventory practices help businesses purchase the right quantities of supplies for each project, reducing both waste and overspending. Efficient material management results in tangible cost savings over time.

Year-Round Preparedness

5S is adaptable to seasonal demands. Whether ramping up for busy spring projects or efficiently managing equipment during slower periods, the methodology helps maintain consistent operational effectiveness throughout the year.

Step-by-Step Implementation of 5S for Landscaping

Implementing 5S in your landscaping business involves focused, manageable steps. Each stage of the methodology builds on the previous one, gradually creating a culture of continuous improvement.

Sort

Begin by identifying items that are needed versus those that are not. Remove broken tools, outdated materials, or equipment that no longer serves a purpose. Clearing clutter from trailers and storage areas creates a more streamlined workspace that enhances both safety and efficiency.

Set in Order

After unwanted items have been removed, organize the remaining tools and materials logically. Designate specific zones for each item—tools used frequently should be easily accessible, while less frequently used items can be stored elsewhere. Labeling and systematic storage solutions ensure that everyone on the team can quickly locate what they need.

Shine

Regular cleaning and maintenance are essential. Schedule routine inspections of tools, machinery, and workspaces to ensure that everything is maintained in optimal condition. A well-cleansed site reduces risks such as equipment malfunction and creates a more pleasant and efficient work environment.

Standardize

Once sorting, organizing, and cleaning are in place, establish standard procedures for everyone to follow. Develop checklists and protocols to document storage layouts, maintenance routines, and cleanup procedures. For example, the Mulch Mule’s features—such as its automated discharge and user-friendly controls—can help promote repeatable processes in material handling, aligning with general best practices in process standardization.

Sustain

The final step is to foster a culture of continuous improvement. Regularly review the 5S practices, conduct training sessions with your team, and update standard operating procedures as needed. Periodic audits and feedback loops can help sustain momentum and encourage employees to identify further improvements. Embracing continuous improvement is key to ensuring lasting benefits.

How the Mulch Mule Supports Efficient Landscaping Operations

The Mulch Mule is designed with several features that support efficient material handling in landscaping. While not explicitly tied to the 5S framework, its operational benefits echo many 5S principles:

- Its large-capacity hopper and live floor system help consolidate bulk materials, reducing clutter and supporting efficient material management by minimizing the need for multiple storage points.

- Automated discharge functions and easy-to-operate controls streamline material handling tasks, reducing the time spent gathering equipment manually.

- Constructed for durability and designed for ease of maintenance, the Mulch Mule simplifies cleaning and upkeep, contributing to sustained operational efficiency.

- Features like remote-controlled discharge improve consistency in material handling processes, promoting uniform practices when transporting and distributing materials across various job sites.

- With its versatile design, the Mulch Mule is suited for a variety of landscaping tasks throughout the year, helping support steady, efficient operations regardless of seasonal changes.

The Mulch Mule stands out as an innovative all-in-one solution, featuring a cutting-edge live floor system, convenient curb-side discharge, and a robust Honda GXi390 engine for unmatched versatility and performance.

Achieve true mulching mastery by effortlessly unloading wheelbarrow loads in just 3-6 seconds, offering a fast and plant-friendly alternative to traditional blowers.

As a trailer, it excels with forward and reverse Live Floor action, simplifying the loading and unloading of skidded materials, complemented by a handheld remote for precise and rapid discharge of various bulk materials.

Real-World Applications of 5S with Enhanced Material Handling

Consider a landscaping team managing public parks and community projects. By first decluttering the jobsite (Sort) and organizing tools on a daily basis (Set in Order), the team lays a strong foundation for efficiency. Regular cleaning and equipment maintenance (Shine) reduce downtime, while documented procedures for material handling, supported by tools like the Mulch Mule (Standardize), ensure consistency across projects. Additionally, OSHA guidelines highlight the importance of reducing hazards at the jobsite to prevent back injuries and other common risks. Finally, routine reviews and training sessions (Sustain) help maintain these improvements.

This integration of disciplined organizational strategies with modern equipment not only accelerates project completion but also minimizes labor costs and enhances overall safety.

Practical Tips for Adopting 5S in Landscaping

Successfully integrating 5S into your landscaping business requires careful planning and teamwork. Here are some practical tips:

- Evaluate Your Current Processes: Conduct a thorough review of tool organization, storage, and material handling to identify inefficiencies.

- Train Your Team: Educate employees about the 5S principles and involve them in developing new procedures. Defined roles and responsibilities encourage team commitment.

- Start Small: Begin by applying 5S practices in high-impact areas such as tool sheds or trailers before expanding organization efforts across the entire operation.

- Set Measurable Goals: Establish clear objectives—like reducing the time spent retrieving tools or lowering equipment downtime—and monitor progress regularly.

- Leverage the Right Equipment: Utilize Mulch Mule attachments and upgrades to further automate tasks and adapt the equipment for year-round applications.

- Conduct Regular Reviews: Schedule periodic audits and team feedback sessions to refine and sustain your 5S practices over time.

Advanced Strategies for Maximized 5S Landscaping Productivity

To further enhance your landscaping operations, consider integrating advanced strategies that complement 5S. Modern digital tools and data-driven management systems can boost productivity and streamline processes.

Integrating Technology with 5S

Digital solutions are increasingly part of the landscaping toolkit when paired with 5S principles. Mobile apps and cloud-based management systems can help schedule maintenance, track tool inventory, and monitor the effectiveness of implemented practices in real time. Incorporating sensor technology into equipment can also help predict maintenance needs, ensuring operations run smoothly and without unexpected downtime. Technologies like predictive maintenance can alert teams before issues arise.

Fostering Team Innovation and Engagement

Outstanding landscaping teams constantly seek improvements beyond standard procedures. Encouraging team members to share their insights and best practices can lead to meaningful, incremental changes that collectively boost efficiency. Regular brainstorming sessions and timely updates to training materials help maintain team engagement and ensure ongoing adherence to well-established practices.

Measuring and Monitoring the Impact of 5S

To ensure that the adoption of 5S is yielding measurable benefits, it is crucial to track performance metrics and monitor outcomes consistently. Establish key performance indicators, such as average project turnaround time, labor hours saved, and the frequency of equipment downtime. Collecting and reviewing this data will allow you to assess the effectiveness of new practices and make necessary adjustments. Regular team meetings and performance reviews provide an opportunity to discuss challenges, celebrate successes, and further refine processes for continuous improvement.

Future Trends in Landscaping Efficiency

Technological advancements and evolving management practices will continue to shape the future of landscaping efficiency. As the industry adapts to rising labor costs and an increasing focus on sustainability, more businesses are exploring integrated systems that combine effective operational practices with modern innovations. F

For example, the integration of Internet of Things (IoT) devices can enable real-time equipment tracking and predictive maintenance, further supporting proactive resource management. Additionally, the emerging use of augmented reality (AR) is gradually influencing landscaping practices by aiding in training and onsite problem-solving.

Addressing Common Challenges in Implementing 5S

While the benefits of 5S are substantial, some challenges may arise during implementation. One common challenge is resistance to change. Employees who are accustomed to traditional methods might be hesitant about new procedures. Overcoming this resistance requires clear communication and hands-on training that demonstrates how streamlined practices improve both safety and efficiency.

Budget constraints can also pose a challenge. Initially, adopting new organizational methods and integrating advanced tools may seem expensive. However, the long-term savings from reduced labor hours, minimized equipment damage, and fewer workplace injuries generally outweigh the initial investment. Viewing 5S implementation as a strategic move that drives longer-term gains can help justify these upfront costs.

Maintaining consistency across multiple job sites can be difficult as well. Different locations may have unique requirements or varying levels of adherence to new practices. Standardized checklists, regular audits, and periodic training sessions help ensure that all teams remain aligned. Sharing success stories and performance improvements across sites can further foster a culture of continuous improvement.

Strategies for Year-Round 5S in Landscaping

Although landscaping work may peak in spring and summer, a structured 5S approach helps teams adapt effectively to all four seasons. During harsh winters, for instance, safety can be enhanced by keeping walkways clear of misplaced materials and tools, minimizing the risk of slips or falls. Storing snow-removal equipment in designated, well-labeled areas ensures that teams locate the right tools quickly when weather strikes.

As leaves accumulate in the fall, setting up dedicated zones for leaf collection supports continuous workflow and eases debris management. This is where equipment like the Mulch Mule—especially when equipped with a vacuum debris loader—can be a game-changer. Instead of manually gathering leaves and spending extra time hauling them off-site, landscaping teams can rely on the Mulch Mule’s live floor system and rapid discharge to speed up cleanup. Well-established 5S practices also streamline regular inspections and maintenance schedules, ensuring that attachments and trailers are ready for each new season’s challenges.

By integrating 5S into year-round routines, landscaping businesses reduce downtime caused by misplaced tools or neglected maintenance. In turn, they can handle more projects efficiently across different climates, leveraging tools like the Mulch Mule to maintain productivity. This comprehensive approach emphasizes not just short-term gains but also the long-term viability of landscaping operations, contributing to both profitability and team safety, no matter the season.

Ready to Enhance your Landscaping Efficiency and Reduce Labor Costs?

Implementing the 5S methodology in landscaping is a powerful strategy for enhancing organization, safety, and productivity. By following the steps—Sort, Set in Order, Shine, Standardize, and Sustain—landscaping businesses can transform their work environments and drive operational efficiency. While equipment like the Mulch Mule is not specifically designed as a 5S tool, its features support efficient practices by reducing clutter, streamlining material handling, and promoting ease of maintenance—benefits that align well with the core goals of 5S.

Check out the Mulch Mule resources to find customer testimonials and video demonstrations of real-world applications. Discover how modern equipment and a disciplined approach to 5S can transform your operations. If you would like to see the Mulch Mule in action, schedule a live demonstration with a Mulch Mule Ambassador Program near you.