Landscaping today faces rising costs, labor shortages, and outdated methods that slow progress and may contribute to worker safety concerns. Modern landscaping professionals need a solution that delivers speed, safety, and significant cost savings. Enter the Mulch Mule—a game-changing piece of equipment designed to automate heavy, repetitive tasks and transform your operations.

What Are Landscape Material Handling Systems?

A landscape material handling system is engineered to move, distribute, and unload bulk materials like mulch, soil, and aggregate with minimal manual intervention. By automating these traditionally labor-intensive processes, such systems reduce staffing needs while enhancing efficiency and potentially lowering safety risks associated with manual labor.

The Mulch Mule trailer serves as a prime example of this innovation, offering a practical integration of technology and functionality for every landscaping business.

To further improve and customize your operations, discover the wide range of Mulch Mule attachments & upgrades that can be incorporated to enhance performance.

Common Challenges in Landscaping Operations

Landscaping professionals often face several critical obstacles:

- High Labor Costs: Traditional methods demand larger teams, leading to higher expenses. Many businesses find that incorporating automation goes a long way in bridging labor shortages. For example, a multigenerational landscaping business can utilize automated equipment to evolve with the industry beyond the traditional standards to address these challenges.

- Worker Safety Concerns: Repetitive heavy lifting can lead to injuries such as back strains.

- Outdated Equipment: Slower, less precise tools delay projects and hinder overall efficiency.

- Limited Capacity: Frequent trips with conventional tools extend project timeframes and magnify labor costs.

Additionally, handling mulch and other materials can be time-intensive. Implementing a mulch and debris removal system for landscapers can aid in mitigating these inefficiencies.

Benefits of Advanced Landscape Material Handling Systems

Switching to an automated system brings transformative benefits, including:

- Lower Labor Costs: Automation minimizes the need for large crews, enabling teams to focus on higher-value tasks.

- Enhanced Safety: Mechanical handling helps reduce the physical strain on workers, potentially lowering injury risks.

- Increased Profitability: Faster project turnaround and reduced downtime allow you to take on more contracts.

- Year-Round Versatility: Reliable in every season, the system efficiently manages a variety of materials including mulch, soil, and debris. Read more about year-round landscaping equipment to see how versatile solutions can keep your business productive all year.

The Mulch Mule: Your Ultimate Material Handling Solution

The Mulch Mule trailer is designed to address the specific operational needs of modern landscaping. It automates the processes of loading, unloading, and even precise material placement, streamlining many demanding tasks. Ideal for both small businesses and large contractors, this system is built with an emphasis on operational efficiency, safety, and long-term durability.

Watch the video below to learn how Mulch Mule can take the load off your employees and pay for itself in the long run by increasing overall profits for your business over time.

Technical Features and Capabilities

Although technical details can be complex, the Mulch Mule’s features are engineered for simplicity and effectiveness. A closer look at its standout capabilities:

High-Capacity Design

- Large Hopper: Featuring a 15-cubic-yard aluminum hopper, the Mulch Mule can manage large volumes of material, reducing the frequency of refills.

- Live Floor System: This innovative mechanism functions similarly to a conveyor belt, continuously moving material during discharge to help spread it evenly.

Precision and Power

- Reliable Engine: Powered by a robust Honda GXi390 Engine, the Mulch Mule ensures consistent performance across a variety of tasks—from light landscaping to heavy-duty material transport.

- Curb-Side Discharge: This feature enables precise placement of materials, reducing waste and ensuring a neat worksite.

Operational Efficiency Simplified

- Rapid Material Handling: By automating material loading, the Mulch Mule significantly decreases repetitive manual tasks, speeding project turnaround.

- Dual-Direction Operation: Designed to facilitate movement in multiple directions during both loading and unloading, the system often reduces the need for repositioning, saving valuable time.

Durability and Adaptability

- Robust Build: Constructed with a reinforced aluminum frame and a high-rated suspension system, the Mulch Mule is built to endure tough conditions and deliver reliable long-term performance.

- Adaptable Design: The system’s flexibility allows it to be employed in various landscaping scenarios, from bulk material transport to on-site distribution.

Practical Applications in Landscaping Projects

The versatility of the Mulch Mule makes it a valuable asset for a wide range of landscaping applications:

- Bulk Material Transport: Quickly move large quantities of mulch, soil, or gravel, keeping your projects on schedule.

- Property Maintenance: Ideal for parks, golf courses, campuses, and commercial properties that require regular upkeep.

- High-Demand Job Sites: Its efficient discharge capability is perfect for projects with tight deadlines.

- Seasonal Versatility: Whether during seasonal cleanup or routine maintenance, this system adapts fluidly to your operational requirements.

By transitioning from traditional methods to advanced systems like the Mulch Mule, you can address labor shortages and unlock new levels of efficiency and growth.

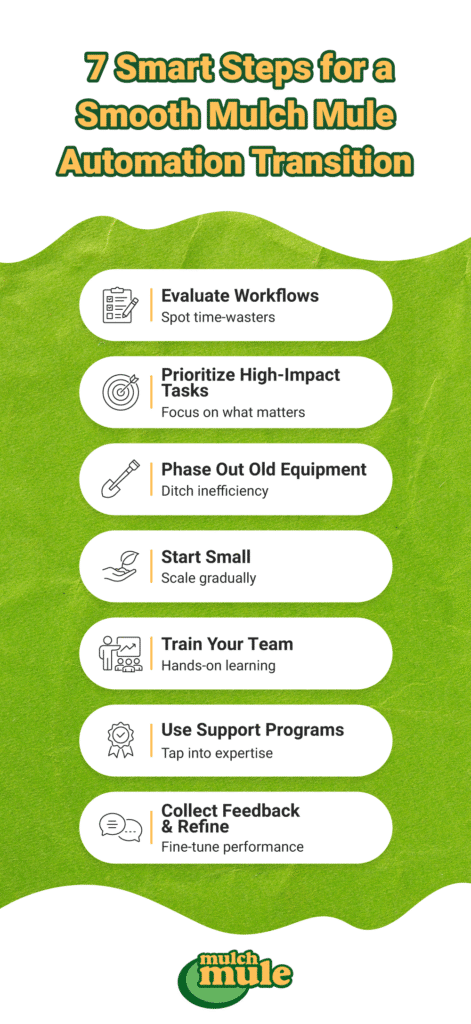

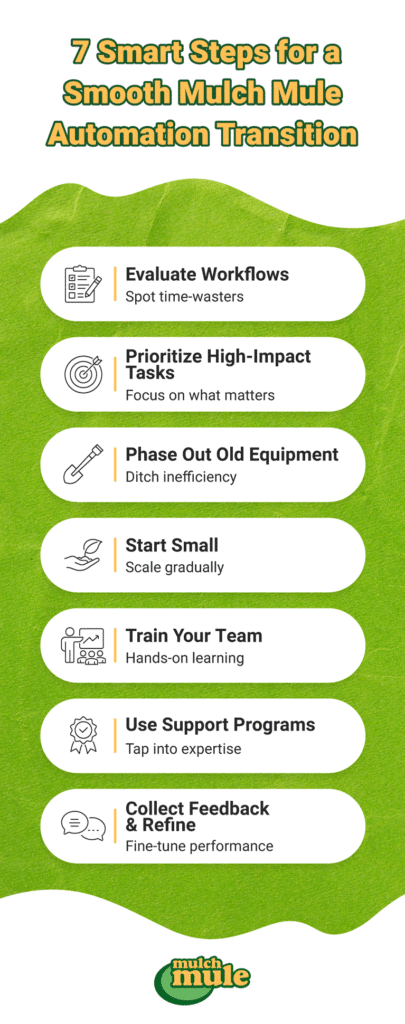

Implementation Strategies for Transitioning to Automation

Switching to the Mulch Mule requires thoughtful planning and phased integration:

Evaluate Existing Workflows

Identify the most labor-intensive tasks and determine where automation can deliver the most impact.

Replace Outdated Equipment

Gradually phase out slower, less efficient tools to streamline your operations.

Training and Onboarding

Organize hands-on practice sessions to ensure your team is comfortable with the new system.

Continuous Feedback

Regularly gather input from operators to fine-tune the integration process and optimize performance.

Potential Drawbacks and Limitations

While the Mulch Mule offers extensive benefits, it is important to consider potential limitations:

- Initial Investment Costs: Acquiring advanced machinery like the Mulch Mule may require a significant upfront outlay.

- Training Requirements: Employees may need dedicated time and resources for effective onboarding and proficiency development.

- Maintenance Planning: Although robust, the system’s moving parts still require consistent servicing and oversight.

Being aware of these factors helps landscaping businesses plan effectively and maximize the return on their investment.

Environmental and Sustainability Benefits

Adopting the Mulch Mule not only improves operational efficiency but also supports environmentally friendly practices:

- Reduced Emissions: Fewer trips between material loads result in lower fuel consumption and a reduced carbon footprint.

- Minimized Waste: Precise material handling minimizes spillage, helping conserve resources.

- Cleaner Work Sites: The system’s integrated design helps control dust and debris, contributing to a healthier work environment.

These sustainability benefits enhance the appeal of the Mulch Mule for businesses committed to environmental responsibility.

Cost Efficiency and Financial Benefits

The Mulch Mule offers a compelling financial proposition:

- Attractive ROI: Reduced labor costs and faster project completion can help offset the initial investment in a short time.

- Lower Maintenance Expenses: Dependable engineering minimizes unexpected repairs, keeping ongoing maintenance manageable.

- Increased Contract Capacity: Streamlined operations enable you to handle more projects simultaneously, boosting overall revenue.

For more insights, review testimonials from satisfied users who have already integrated the Mulch Mule into their workflows.

Maximizing ROI with Smart Integration of a Landscape Material Handling System

To fully benefit from the Mulch Mule, consider these strategies:

- Assess and Refine Workflows: Identify process bottlenecks where the new system can save time and increase efficiency.

- Streamline Processes: Use automation to reduce repetitive tasks and decrease operational downtime.

- Invest in Comprehensive Training: Ensure each team member understands the equipment’s features to maximize productivity.

- Monitor Performance: Regularly review operations to gauge improvements and fine-tune strategies accordingly.

These proactive steps will help you reap the full financial and operational benefits of the Mulch Mule.

Leveraging Real-Time Monitoring and Analytics

Modern systems like the Mulch Mule can be integrated with real-time monitoring tools, offering considerable advantages:

- Instant Adjustments: Real-time data allows operators to make immediate tweaks for optimal performance.

- Predictive Maintenance: Sensors can signal early signs of wear and tear, helping avert costly breakdowns.

- Data-Driven Decisions: Continuous insights into system performance empower you to optimize resource allocation and further refine operational processes.

For a closer look at how technology integrates with current landscaping practices, explore video demonstrations that showcase the equipment in action.

Future Trends and Technological Innovations

The landscaping industry continues to evolve as new technologies emerge. Expect future advancements such as:

- IoT Integration: More connected systems sharing data in real time.

- Enhanced Predictive Maintenance: Innovations that further minimize downtime and extend equipment life.

- Eco-Friendly Upgrades: Advances in sustainable materials and renewable energy sources that promise even greener landscaping tools.

Staying alert to these trends will help you plan for long-term growth and future-proof your operations.

Long-Term Integration and Workforce Transformation

Adopting advanced systems like the Mulch Mule not only improves efficiency but also transforms workforce dynamics:

- Evolving Roles: As automation handles routine tasks, employees can focus on strategic activities like project planning and customer engagement.

- Skill Development: Ongoing training on new technologies fosters professional growth and adaptability.

- Sustainable Advantages: By leveraging real-time data, a tech-savvy workforce is empowered to continuously enhance job performance and overall efficiency.

This transformative approach fosters a culture of innovation and positions your business for future success.

Operational Best Practices for Longevity

To ensure the Mulch Mule delivers lasting performance, adopt these best practices:

- Routine Maintenance: Schedule regular inspections and servicing to maintain optimal functionality. Consult the parts and warranty guidelines for detailed information.

- Continuous Operator Training: Regular training sessions reinforce safe practices and improve overall efficiency.

- Preventative Care: A consistent maintenance regimen helps prevent unexpected breakdowns and reduces downtime.

Implementing these measures extends the equipment’s lifespan and ensures reliable performance on every job site.

Elevate Your Landscaping Efficiency Today

The Mulch Mule is more than an advanced piece of machinery—it represents a transformative change in landscaping operations. By automating labor-intensive tasks, reducing costs, enhancing safety, and supporting sustainable practices, the Mulch Mule empowers you to handle more projects, meet deadlines, and enhance profitability.

Take the first step toward revolutionizing your landscaping operations. Contact our experts today for an exclusive Mulch Mule demonstration and start transforming your business now.