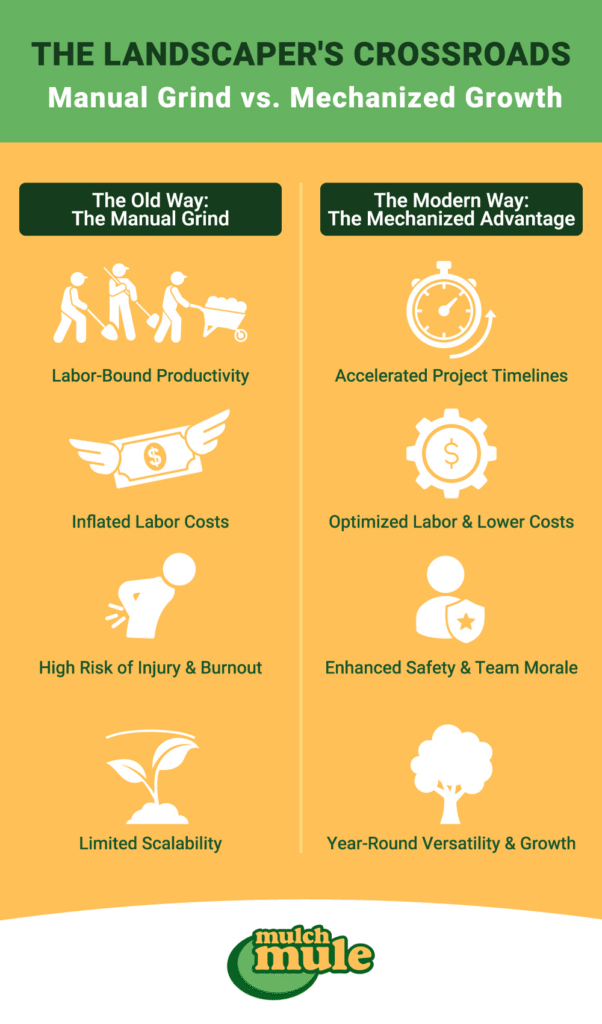

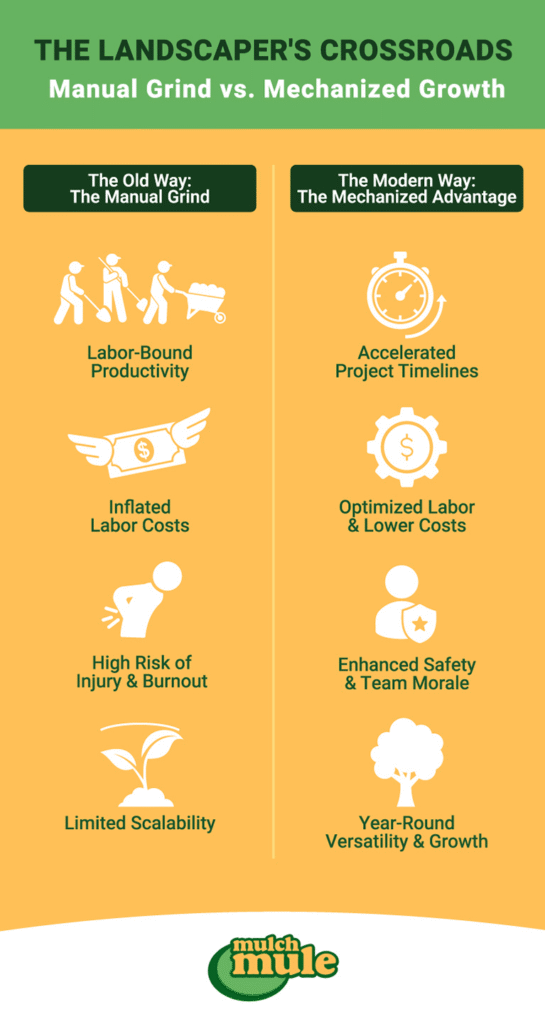

Landscaping companies today face demanding workloads, tight deadlines, and rising labor costs. Advanced landscaping trailers offer a transformative solution by automating tasks and streamlining operations. These tools simplify the movement, storage, and distribution of materials such as mulch, soil, stone, and debris—turning project management from a labor-intensive process into a more efficiently managed operation. For instance, the Mulch Mule Trailer helps reduce physical strain on workers while aiming to improve project timelines and overall profitability.

Traditional manual methods often limit capacity and introduce inefficiencies. As customer expectations for speed and quality rise, investing in equipment like landscaping trailers and loaders becomes an important consideration. For landscaping, lawncare, and property maintenance companies, material handling equipment is more than a convenience—it is a strategic asset that can increase productivity, boost employee satisfaction, and enhance a company’s competitive edge.

The Triple-Threat Advantage: Boosting Productivity, Safety, and Savings

Modern material handling equipment transforms landscaping operations by delivering a powerful trifecta of interconnected benefits: accelerating productivity, enhancing workplace safety, and driving significant cost savings. These three pillars work in concert to create a more resilient, efficient, and profitable business. By addressing the most labor-intensive aspects of landscaping, tools like the Mulch Mule don’t just improve one area of your business—they elevate the entire operation.

Boosting Landscaping Productivity with Advanced Equipment

First and foremost, advanced equipment is a catalyst for unparalleled productivity. Mechanized solutions manage essential tasks—such as distributing mulch, clearing debris, and transporting heavy materials—at a speed that manual crews simply cannot match. For example, the live floor system integrated into the Mulch Mule trailer is designed for constant, efficient material handling, helping landscaping teams dramatically reduce the downtime spent on loading and unloading. This allows them to transition smoothly and quickly between projects. Furthermore, the equipment’s versatility allows a single machine to handle diverse tasks, from spreading mulch in the spring to managing leaves or gravel in the fall, which reduces the need for multiple specialized machines and streamlines your entire workflow. This surge in productivity not only boosts efficiency but also enhances a company’s reputation for reliability and professionalism, leading to improved client satisfaction and better operational performance.

Transitioning to Cost Savings: Reducing Labor Costs and Improving Workforce Efficiency

As productivity increases, businesses naturally enjoy significant and measurable cost savings. The primary driver of these savings is a reduction in labor dependency. By automating material handling, companies can accomplish more with smaller, more focused crews, reallocating skilled workers from strenuous manual labor to more value-added activities like detailed garden work or client relations.

Key Advantages of Automation in Labor Efficiency:

- A single operator can manage loading and unloading processes that would have previously required several employees.

- The Mulch Mule’s rapid wheelbarrow-filling mechanism directly accelerates task completion, meaning fewer labor hours are billed to each job.

- Fewer employees are needed for repetitive manual tasks, allowing valuable team members to focus on creative and strategic activities that grow the business.

This streamlined approach not only helps lower direct labor expenses but also creates a more efficient and cost-effective operational model.

Enhancing Workplace Safety and Employee Morale

Finally, and perhaps most importantly, this operational shift fundamentally enhances workplace safety and boosts employee morale. The manual handling of heavy landscaping materials is a leading cause of debilitating injuries, including chronic back strains and repetitive stress conditions that harm both worker health and company productivity. By automating these physically demanding tasks, the Mulch Mule reduces the physical burden on employees, fostering a safer and more positive work environment.

Key safety benefits include:

- A tangible decrease in the incidence of back strain and other common repetitive injuries.

- Potential reductions in workers’ compensation claims and related insurance costs.

- Improved employee morale as workers engage in less physically demanding, more fulfilling tasks.

This focus on safety protects your team and helps build a supportive work culture that attracts and retains skilled professionals, reducing turnover and supporting long-term business success. When employees feel valued and are not subjected to grueling physical labor, their morale improves, leading to higher quality work and a more engaged, stable workforce.

Designed for All Seasons: The Mulch Mule’s Unique Features and Versatility

The Mulch Mule is recognized for its robust design and multifunctional capabilities, which together create a powerful, year-round asset for any landscaping business. Unlike seasonal tools designed for temporary use, its value lies in a core set of innovative features that enable it to operate effectively in various weather conditions and handle a wide range of materials. This all-in-one approach means companies do not have to invest in multiple pieces of seasonal equipment, thereby simplifying maintenance, streamlining training, and maintaining high productivity regardless of the season.

Innovative All-in-One Design

At the heart of its functionality is a design engineered for maximum efficiency and minimal manual labor.

- Live Floor System: Features a state-of-the-art live floor system that ensures consistent, smooth material movement from the hopper to the discharge point, preventing clogs and enabling precise control.

- Curb-Side Discharge Mechanism: Incorporates a unique curb-side discharge chute that minimizes the need for manual spreading and reduces physical strain, allowing for faster and more accurate material placement directly into wheelbarrows or onto landscape beds.

Enhanced Debris and Leaf Management

The Mulch Mule extends its utility far beyond standard material hauling with specialized components for cleanup tasks.

- Powerful Vacuum Debris Loader: Equipped with a high-capacity vacuum debris loader, it makes seasonal cleanups, such as leaf removal, incredibly efficient.

- Automatic Tarping System: Includes an automatic tarping system to minimize spills, contain dust, and ensure a clean, professional job site.

High Capacity and Efficient Operation

Every component is designed to maximize uptime and reduce operational friction, allowing crews to get more done in less time.

- 15-Cubic-Yard Aluminum Hopper: Features a large-capacity, lightweight aluminum hopper that helps reduce the frequency of trips for reloading, saving valuable time and fuel.

- Ergonomic and Remote Controls: A combination of ergonomic controls and a handheld remote allows for safer, more precise, and more effective operation, giving the user full command over the equipment from a safe distance.

From Features to Function: A Tool for Every Season

These integrated features directly translate into unmatched, year-round versatility, allowing the Mulch Mule to adapt to diverse materials and environmental challenges:

- In the fall, its powerful vacuum debris loader becomes a primary asset, efficiently clearing and hauling vast quantities of fallen leaves.

- During winter, its robust build can transport heavy aggregate for repairs or be used to clear storm debris, keeping crews productive in the off-season.

- Throughout the spring and summer, it excels at managing a wide assortment of materials including mulch, soil, stone, and aggregate, making it the central workhorse for daily operations.

By delivering this consistent, all-season performance, the Mulch Mule proves itself as a reliable, user-friendly solution capable of addressing complex landscaping needs with greater ease and efficiency.

Watch the video below to learn more about how Mulch Mule provides invaluable features for landscaping businesses.

Making the Switch: Implementation & Long-Term Care

Purchasing advanced material handling equipment is the first step toward transforming your operations. However, maximizing its long-term value and achieving a significant return on investment depends on a well-thought-out implementation strategy and a commitment to proactive care. By integrating the Mulch Mule thoughtfully into your business and establishing strong maintenance practices from day one, you can ensure a smooth transition, protect your investment, and unlock its full potential for years to come.

Tips for a Successful Implementation Strategy

For businesses transitioning to advanced machinery, a clear plan is crucial. Consider the following steps to maximize the benefits of the Mulch Mule Trailer and ensure your team is set up for success:

- Assess Current Workflows: Before the equipment arrives, evaluate your current tasks. Identify which processes are the most labor-intensive or time-consuming and pinpoint exactly where automation will yield the most significant efficiency gains. This allows you to create a targeted integration plan.

- Invest in Comprehensive Training: A smooth transition hinges on your team’s confidence and competence. Ensure every operator receives hands-on training and understands the clear operational guidelines provided by the manufacturer. Proper training minimizes errors, enhances safety, and accelerates adoption.

- Monitor Key Performance Indicators (KPIs): To validate the impact of your investment, track key metrics from the start. Monitor changes in project completion times, labor cost per job, material waste, and safety incidents. This data will help you quantify the benefits and refine your operational strategies over time.

Maintaining Your Equipment for Long-Term Success

Maximizing the benefits of your material handling equipment depends on proactive, preventative maintenance. Regular service routines are essential to ensure that the Mulch Mule remains in peak condition, preventing costly downtime during your busiest seasons. Consider these best practices for long-term reliability:

- Establish a Routine Service Schedule: Work with your team to create and follow a regular service schedule. Routine inspections allow you to catch and address minor issues, like wear on a belt or a loose fitting, before they develop into major, costly repairs.

- Prioritize Cleaning of Critical Components: Keep critical components, such as the live floor system and discharge chute, clean and free of debris. Regular cleaning prevents blockages, reduces unnecessary wear and tear, and ensures consistent, reliable performance.

- Maintain Direct Contact with Your Equipment Provider: A strong relationship with your equipment provider is a valuable asset. This ensures you have timely access to genuine parts, expert technical support, and the latest service protocols from the manufacturer to keep your machine running smoothly.

From Misconception to Modernization: Navigating the Future of Material Handling Equipment

As the landscaping industry evolves, so does the technology that drives it. However, with any significant leap forward, outdated perceptions can persist. Making a strategic investment in modern equipment requires separating long-held myths from the reality of today’s innovations. By understanding both the common misconceptions and the emerging technological trends, forward-thinking companies can confidently position themselves for future success.

Addressing Common Misconceptions About Modern Equipment

Despite the well-documented benefits of advanced material handling solutions, a few myths still circulate. Addressing these is key to making an informed decision about the future of your operations.

Misconception: The high initial cost makes it unattainable for smaller companies.

Reality: This view overlooks the crucial concept of Return on Investment (ROI). While advanced equipment is a significant investment, its value is measured in long-term operational savings, increased capacity, and reduced labor dependency. The speed at which this investment is recovered depends on factors like workload and job volume, but for many, the financial returns from completing more jobs with fewer labor hours justify the initial outlay. The question isn’t just “What does it cost?” but “What is the cost of not upgrading?”

Misconception: The equipment is too complex, and training is a major hurdle.

Reality: Unlike the cumbersome machinery of the past, modern equipment like the Mulch Mule is engineered with the user in mind. Designs feature intuitive, ergonomic controls and often include handheld remotes for safer, more precise operation. Manufacturers provide comprehensive training programs and resources, ensuring that teams can transition smoothly and confidently to the new systems.

Misconception: Its application is too limited to be a year-round asset.

Reality: Versatility is a cornerstone of modern design. The Mulch Mule, for example, is engineered to handle a wide range of materials—from mulch and soil to stone and aggregate—and is equipped with features like powerful vacuum debris loaders for seasonal cleanups. This adaptability ensures it remains a productive asset throughout the year, not just during peak season.

Emerging Trends and the Path Forward

Dispelling these myths is the first step. The next is to embrace the technological advancements that are reshaping the industry. Staying ahead of these trends can provide a significant competitive advantage.

- Smart Technology Integration: The future of material handling lies in smart features. Emerging trends include the use of IoT (Internet of Things) devices for real-time equipment monitoring and predictive maintenance alerts, which help reduce unexpected downtime. Sensor technology and artificial intelligence are also being developed to optimize material distribution and enhance on-site efficiency.

- A Growing Focus on Sustainability: As the industry moves toward more environmentally conscious practices, equipment is evolving to meet these demands. Innovations include cleaner emissions and fuel-conserving designs that reduce both environmental impact and operational costs. Upgrading to modern equipment today sets the foundation for a more sustainable business model tomorrow.

By investing in technologically advanced equipment like the Mulch Mule, landscaping companies are not just solving today’s labor and efficiency problems—they are preparing for the future. Embracing these innovations allows businesses to operate more intelligently, sustainably, and profitably in an ever-changing market.

Transforming Landscapes with Advanced Material Handling Equipment

In today’s competitive landscaping market, advanced material handling equipment is no longer a luxury—it is the key to transforming your operations. By automating the most physically demanding and time-consuming tasks, solutions like the Mulch Mule empower your business to break through previous limitations. This strategic shift enables you to manage larger projects, control labor costs, enhance workplace safety, and ultimately drive greater, more sustainable profitability.

Ready to elevate your operations? See how the Mulch Mule can redefine what’s possible for your business by exploring live demonstrations and reviewing real-world customer testimonials. Contact our team today to unlock new levels of efficiency, safety, and growth.