In today’s competitive landscaping market, managing the transportation and distribution of bulk materials efficiently is crucial. Many professionals face challenges such as labor-intensive work, tight deadlines, and safety risks. A well-designed material handling trailer can automate certain tasks, potentially reducing labor costs while contributing to increased jobsite productivity and improved safety. Tools like the Mulch Mule trailer simplify loading, unloading, and material distribution, enabling your team to work faster and more efficiently.

This article explains the benefits of material handling trailers and how they transform landscaping operations. We’ll explore their key features, operational and financial advantages, versatile applications, and the positive impact on both safety and efficiency.

What are Material Handling Trailers?

Material handling trailers are specialized tools that help automate the transport, distribution, and collection of landscaping materials such as mulch, soil, debris, and aggregates. Unlike traditional manual methods, which often lead to delays and increased labor costs, these trailers streamline workflows with features that help automate tasks and provide better control over material handling.

By reducing the need for manual shoveling and extra manpower, modern trailers can help improve project timelines while also enhancing safety through a decrease in repetitive heavy lifting. According to U.S. Bureau of Labor Statistics data, repetitive bending and lifting remain contributing factors to workplace injuries in the landscaping sector.

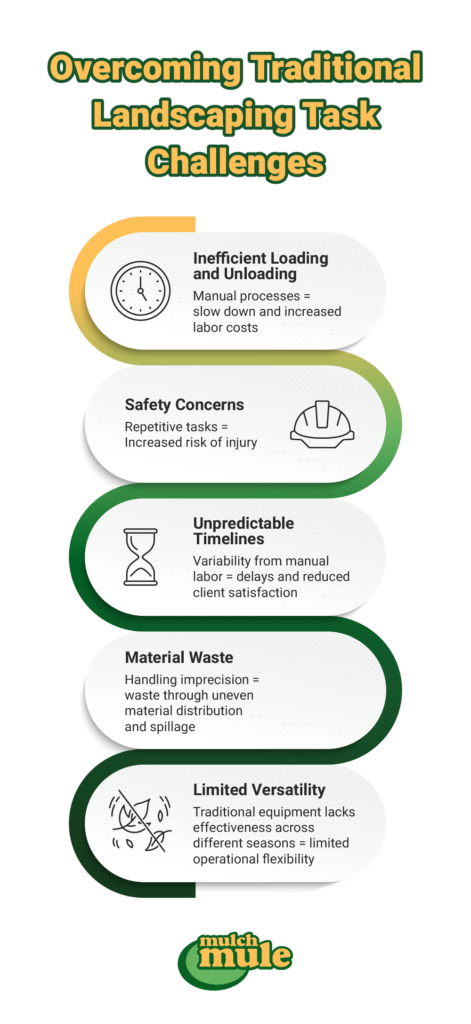

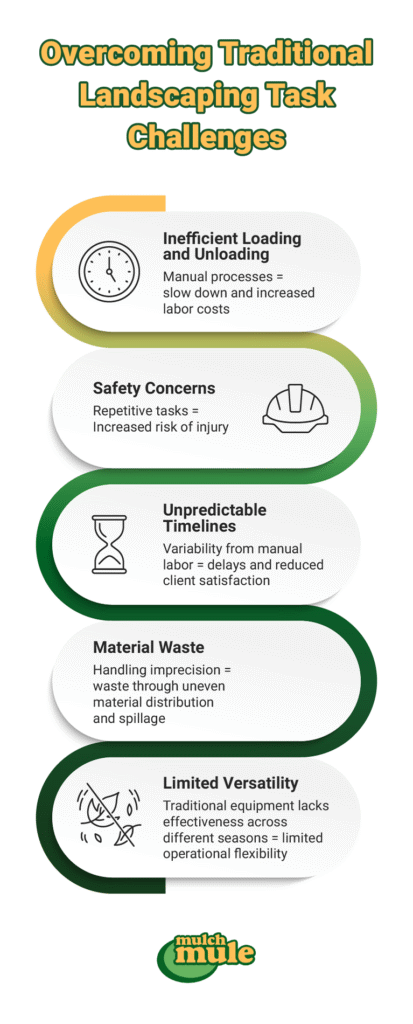

Common Challenges in Traditional Landscaping Tasks

Traditional landscaping methods often involve manual material handling, which is time-consuming and physically demanding. Key challenges include:

Inefficient Loading and Unloading

Manual methods can slow project progress, require extra manpower, and drive up labor expenses.

Safety Concerns

Repetitive bending, lifting, and shoveling increase the risk of injuries and long-term health issues, often resulting in higher workers’ compensation claims. For guidance on mitigating such risks, consult landscaping safety guidelines and proper lifting techniques.

Unpredictable Timelines

Variability due to manual labor, fatigue, or worker shortages can extend project deadlines and reduce client satisfaction.

Material Waste

Imprecise handling can lead to uneven distribution and spillage, causing material waste and additional cleanup needs.

Limited Versatility

Equipment that works well in one season may be less useful in another, limiting operational flexibility.

By automating many of these processes, material handling trailers address these challenges with more streamlined, faster, and safer operations.

Key Features of a High-Quality Material Handling Trailer

Modern material handling trailers offer a host of features designed for increased efficiency and ease of use:

Generous Capacity Hopper

A large capacity hopper made from lightweight, durable materials minimizes the number of trips required for transporting bulk materials efficiently. For example, the Mulch Mule trailer features a 15-cubic-yard aluminum hopper designed for rapid unloading. This substantial capacity helps reduce downtime and accelerates project timelines.

Live Floor Technology

Automated live floor systems provide rapid loading and unloading, minimizing the need for manual labor. The system’s forward and reverse functionality helps ensure smooth material flow.

Reliable Engine Performance

Engines such as the Honda GXi390 deliver the strength needed for heavy-duty tasks, supporting consistent performance and reducing downtime.

Versatile Attachments

Optional attachments, such as vacuum debris loaders and tarping systems, add year-round versatility.

Precision Remote Control

Handheld controls allow for precise material placement, reducing waste and ensuring that work meets high standards.

Durable Construction

Built with high-quality materials and reinforced frames, these trailers are designed to withstand demanding jobs while requiring minimal maintenance.

User-Friendly Design

Ease of operation is essential—features like hydraulic jacks and smooth suspension systems simplify setup and reduce physical strain on operators.

Want to learn more about the Mulch Mule trailer? Watch this video below to hear straight from the inventor of Mulch Mule on how it came to be and how economic and efficient it can be for your landscaping business.

Operational Benefits of Material Handling Trailers

Integrating a material handling trailer into your landscaping operations can provide several benefits:

Accelerated Workflow

Automated loading and unloading allow crews to complete tasks more quickly than through manual methods, potentially speeding up project completion and enabling the handling of more jobs.

Enhanced Crew Productivity

With reduced manual labor, workers can focus on specialized tasks, allowing for a more efficient allocation of resources and overall increased productivity.

Reduced Downtime

Rapid reloading and transport capabilities help reduce wait times between tasks, keeping projects on schedule.

Improved Jobsite Precision

Controlled material distribution contributes to an even, professional finish, enhancing client satisfaction and bolstering your company’s reputation.

Financial and Productivity Advantages

Material handling trailers can offer significant financial benefits:

Lower Labor Costs

By automating various tasks, these trailers have the potential to reduce the need for extensive manual labor, which can help ease payroll expenses while also cutting down on overtime.

Increased Profit Margins

The efficiency gains from automated systems help minimize delays and material waste, contributing in turn to improved profitability on individual projects.

Enhanced Employee Retention

Reducing the physical demands of material handling not only helps protect workers’ health but also improves morale, potentially reducing turnover and fostering a more stable workforce.

Year-Round Use

Versatile trailers can be used for a range of tasks across different seasons, maximizing their value and ensuring continuous productivity regardless of changing operational demands.

Potential Quick Return on Investment

Although many landscaping businesses report that improved project efficiency and reduced labor requirements help offset the cost of a material handling trailer, the timeframe for a return on investment varies business to business. Some operators experience noticeable benefits relatively quickly; however, actual payback periods depend on individual operational factors. Check out these testimonials to see how the Mulch Mule trailer enhanced businesses employee morale and productivity over time.

Applications in Landscaping

Material handling trailers are versatile tools applicable across a variety of landscaping tasks:

Mulch and Soil Distribution

Automated systems help deliver and spread materials evenly, reducing the need for manual shoveling and minimizing waste.

Stone and Aggregate Placement

These trailers enable precise transport and distribution of heavy materials like sand or gravel for decorative features, paths, or foundations, which can result in less cleanup time.

Leaf and Debris Cleanup

Optional vacuum debris loaders simplify seasonal cleanup by efficiently gathering leaves and grass clippings.

Property Maintenance

Homeowners associations, golf courses, and public parks can benefit from the consistent and timely upkeep provided by material handling trailers.

Nursery Operations

Nurseries and garden centers can efficiently move large volumes of soil, compost, or mulch for both bulk deliveries and in-store use.

Environmental Benefits of Thoughtful Material Handling

Material handling trailers can support environmentally responsible practices in line with sustainable logistics principles. Efficient transport mechanisms can help lower fuel consumption, while the long-term durability of well-constructed equipment reduces the frequency of replacements and, consequently, manufacturing waste. Although specific studies on material handling trailers are limited, these design principles generally contribute to reducing environmental impact.

Safety and Workforce Motivation

Modern material handling trailers help enhance safety on the jobsite:

Reduced Physical Strain

Automated features that limit repetitive lifting and bending can help lower the risk of injuries such as back strains and muscle fatigue.

Improved Morale

Investing in equipment that reduces manual labor demonstrates a commitment to employee wellbeing, which may in turn enhance morale and reduce turnover.

Streamlined Workflow

Clearly defined roles paired with automated processes foster teamwork and increase overall jobsite efficiency.

Professional Image

Utilizing advanced, reliable equipment enhances your company’s reputation for safety and efficiency, potentially attracting more referrals and long-term contracts.

Maintenance and Longevity Strategies

In addition to operational benefits, a proactive maintenance strategy is key to extending the lifespan of your material handling trailer. Regular inspections, scheduled maintenance, and adherence to manufacturer guidelines can all help prevent costly breakdowns and prolong the equipment’s useful life.

Simple practices such as cleaning the trailer after each use, checking hydraulic systems regularly, and ensuring that moving parts are properly lubricated are essential. Training operators on proper usage and troubleshooting common issues also contributes to longevity, ensuring that the trailer consistently delivers optimal performance.

Potential Drawbacks and Considerations

While material handling trailers offer many advantages, it’s important to remain aware of certain limitations and practical factors:

- Initial Cost Outlay: Purchasing advanced equipment may present a higher upfront cost. Businesses should assess whether the long-term savings in labor and project turnaround will offset that investment.

- Required Training: Staff may need dedicated training to operate new systems safely and efficiently, requiring additional time and resources.

- Maintenance and Repairs: Although trailers are built for durability, regular maintenance or unexpected repairs can result in downtime and added expenses.

- Space and Transportation Needs: Smaller operations must evaluate whether they have adequate space for storing and maneuvering the trailer when not in use.

Balancing these considerations with the potential operational benefits helps businesses make a more informed and objective decision when investing in new equipment.

Maximizing ROI and Operational Excellence

Adopting a material handling trailer like the Mulch Mule can significantly impact a landscaping company’s operational efficiency and overall profitability. Enhanced project efficiency and reduced labor needs have the potential to help offset the investment in such equipment over time. However, the exact period required to achieve a full return on investment can vary according to individual business circumstances, operational workflows, and project scales. For strategies on expanding your landscaping enterprise, see these growth tips for landscaping businesses.

Implementation Best Practices and Continuous Improvement

To fully benefit from material handling trailers, it is important to implement best practices and focus on continuous improvement. Start by establishing a comprehensive training program to ensure that all operators understand the trailer’s functionalities, safety protocols, and maintenance requirements. Such foundational knowledge minimizes the risk of misuse and ensures optimal performance from the equipment. Regular performance evaluations can help identify areas for further improvement—tracking time savings per project and analyzing maintenance patterns are effective ways to refine operational processes.

Fostering a culture of continuous improvement among teams can drive innovation in daily operations. Encouraging operators to provide feedback and report issues creates a collaborative environment where all team members contribute actively to operational excellence. Moreover, integrating tools that monitor real-time performance and facilitate prompt troubleshooting can further enhance overall productivity. This proactive approach not only improves workflow efficiency but also ensures that material handling strategies remain sustainable and effective over the long term.

Can a Material Handling Trailer Boost Your Efficiency?

Addressing the challenges of manual material handling is essential for any successful landscaping operation. Material handling trailers provide a comprehensive solution by automating many labor-intensive tasks, enhancing jobsite safety, and boosting overall productivity and profitability.

Incorporating a trailer with advanced features such as a live floor system and precision control can enable your team to complete projects more efficiently and at a higher quality. As technology continues to evolve, so too will the benefits associated with these systems—though the specific operational gains and return on investment may vary with each application.

Exploring a material handling trailer like the Mulch Mule could be a smart long-term investment for landscaping companies aiming to optimize operations while managing labor costs.

Ready to explore how a material handling trailer can enhance your landscaping efficiency? Contact the Mulch Mule team today to schedule a demonstration and discover how automated solutions can drive your business forward.