In the fast-paced worlds of landscaping, municipal maintenance, and construction, efficiency is key. Moving large volumes of materials quickly and effectively can set businesses apart from the competition. For professionals juggling tight deadlines, labor shortages, and rising costs, advanced bulk material handling systems provide a transformative solution. These cutting-edge systems streamline labor-intensive processes, help reduce costs, improve project timelines, and enhance workplace safety by applying safer, more efficient handling practices that align with established safety frameworks.

This article delves into the core benefits of employing advanced bulk material handling technologies, the industry challenges they address, and why tools like the Mulch Mule are redefining efficiency in modern operations. Whether it’s boosting productivity, improving profitability, or creating a safer work environment, these systems empower businesses to thrive in a competitive landscape.

What Are Advanced Bulk Material Handling Systems?

Advanced bulk material handling systems are specialized tools and equipment designed to simplify and automate the processes of loading, transporting, and distributing materials like mulch, debris, soil, gravel, and more. Unlike traditional manual methods that rely heavily on labor-intensive efforts, these systems utilize technology to optimize efficiency and reduce physical strain on workers. Industry sources note that such automation not only speeds up operations but also supports a safer working environment, while market research reports have observed that robust handling equipment contributes to long-term cost-effectiveness.

These systems include a variety of innovations that streamline material handling, such as:

- Trailers equipped with automated loading and unloading mechanisms

- Live floor systems — also known as walking floors or live bottom systems — that move materials smoothly for controlled unloading

- Attachments like vacuum loaders or conveyor belts for handling debris and other bulk materials

- Automated controls, including remote-operation capabilities, for precise and hands-free management

By integrating features such as motorized conveyors, hydraulic systems, and smart controls, advanced bulk material handling systems revolutionize traditional labor-intensive tasks, reducing the time and effort required for high-volume operations while ensuring consistent results.

The Challenges Faced by Landscaping Professionals

Landscaping professionals face numerous challenges that can make daily operations both demanding and inefficient. From managing fluctuating workloads to addressing safety concerns and rising operational costs, these obstacles impact profitability, scalability, and employee well-being.

1. Labor Shortages

Hiring and retaining skilled workers has become a major hurdle, a challenge compounded by the physically demanding nature of landscape work. High turnover rates leave companies understaffed, especially during peak seasons.

2. Safety Risks and Employee Well-Being

Manual material handling tasks inherently carry safety risks. Research has shown that repetitive lifting and awkward postures can lead to injuries, resulting in downtime, higher workers’ compensation claims, and lower morale.

3. Inefficient Manual Processes

Shoveling and hand-spreading are time-consuming tasks prone to human error. These traditional methods often lead to uneven material distribution and delayed project timelines.

4. Rising Operational Costs

Relying heavily on manual labor inflates wages, overtime expenses, and training costs. In addition, increased fuel consumption and equipment maintenance further strain budgets.

5. Limited Scalability for Growing Businesses

For companies aiming to expand, labor-intensive processes require hiring and training more staff, which may not scale efficiently in response to growing project demands.

Key Benefits of Advanced Bulk Material Handling Systems

For landscaping professionals looking to overcome these obstacles, automation offers a compelling solution. Advanced bulk material handling systems provide several key benefits:

Increased Productivity and Time Savings

Automation significantly reduces the time needed for tasks such as loading, unloading, and material distribution. For instance, live floor systems minimize downtime and accelerate job completion. Various industry observations confirm that improved automation translates into faster project turnaround times.

Reduced Labor Costs

By shifting employees away from repetitive tasks like shoveling or loading, businesses can reallocate human resources toward specialized, higher-value functions. This strategic approach helps lower overall labor costs and enhances operational efficiency, reflecting widely recognized principles of resource optimization.

Enhanced Worker Safety

Reducing reliance on manual labor minimizes risks associated with heavy lifting and repetitive motions. Features such as remote-controlled operations and automated discharge systems further protect workers and contribute to a safer work environment.

Versatility Across Diverse Applications

These handling systems work effectively year-round, capable of managing various materials from mulch to debris. Their ability to adapt to different materials and project requirements makes them valuable assets throughout the year.

Long-Term Cost Savings and Improved ROI

While the initial investment in automation may be significant, the long-term savings in labor, reduced injury-related costs, and faster project completions contribute to a robust return on investment. Over time, these efficiencies help businesses grow without corresponding increases in labor expenses.

Introducing the Mulch Mule: A Solution for Modern Landscapers

When streamlining material handling and optimizing landscaping operations, the Mulch Mule trailer system is a standout innovation. Developed to address current industry challenges, the Mulch Mule simplifies loading, transporting, and unloading bulk materials, offering solutions to labor shortages, extended project timelines, and safety concerns.

Exceptional Capacity and Swift Unloading

Designed for high-volume demands, certain Mulch Mule models feature hopper capacities of up to 15 cubic yards. An efficient live floor system supports swift and controlled discharge, significantly reducing unloading times compared to traditional methods.

Year-Round Versatility

Capable of handling diverse materials such as mulch, soil, leaves, and stone, the Mulch Mule provides consistent performance across seasons. Its adaptability minimizes the need for multiple specialized tools and consolidates maintenance costs.

Safety-Focused Design

With features like remote control and controlled unloading mechanisms, the Mulch Mule mitigates the risks associated with manual material handling. By reducing physical strain on workers, it plays a key role in enhancing overall workplace safety.

Customizable Features for Diverse Needs

Optional accessories, including vacuum loaders and specialized attachments, extend the functionality of the system, allowing it to meet varied job site requirements and further streamline operations.

Designed to transport and distribute soil, mulch, leaves, debris, stone and aggregate to save you time and money. Many satisfied customers have seen measurable results with Mulch Mule.

Watch the video below for a walk around of this invaluable equipment.

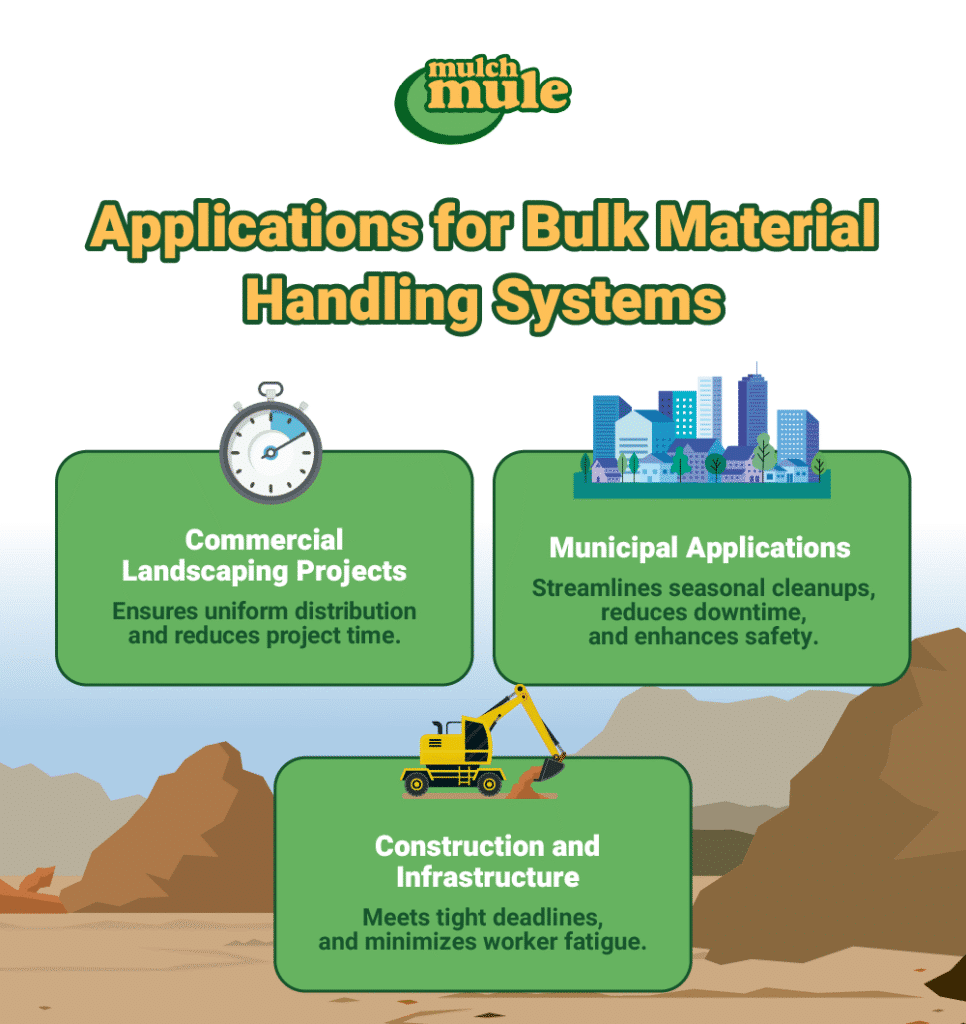

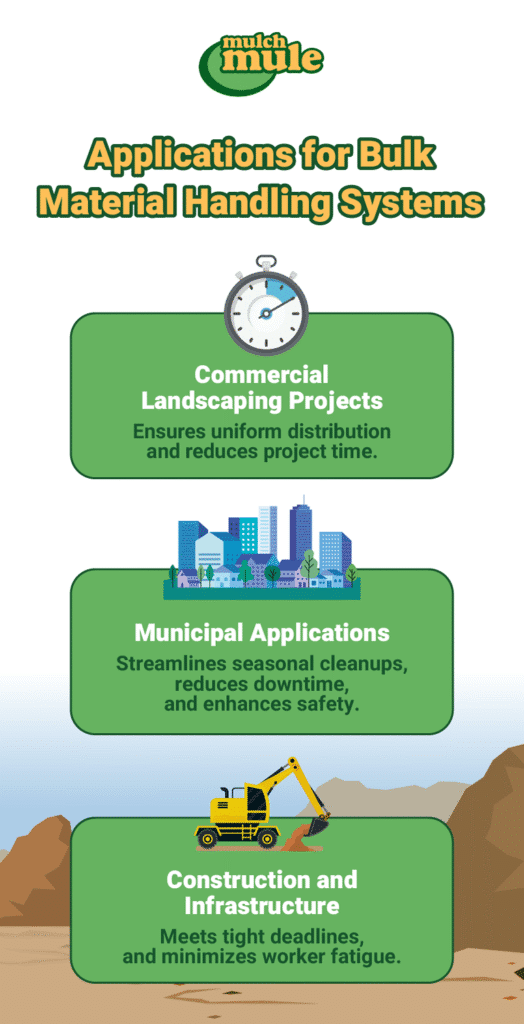

Real-World Applications of Advanced Bulk Material Handling Systems

Landscaping professionals, municipalities, and construction companies are finding that automation in material handling dramatically boosts operational efficiency. Whether in commercial landscaping projects, municipal leaf and debris collection, or large-scale residential maintenance, these systems provide significant advantages by reducing manual labor and increasing overall productivity.

Commercial Landscaping Projects

For extensive properties, automated material handling ensures uniform distribution of bulk materials across large areas, substantially reducing project turnaround times.

Municipal Applications

Cities benefit from automation by streamlining seasonal cleanups and debris management, which minimizes downtime and improves the overall safety of municipal operations.

Construction and Infrastructure

Contractors can rely on robust handling equipment to move large quantities of materials quickly, positioning them to meet tight deadlines and reduce worker fatigue.

Evaluating the ROI of Investing in Automation for Your Landscaping Company

When considering an investment in advanced bulk material handling equipment, such as the Mulch Mule, it’s essential to look beyond the upfront cost and focus on the long-term return on investment (ROI). For landscaping businesses, automation doesn’t just represent a technological upgrade—it’s a strategic move that can transform operational efficiency, labor allocation, and overall profitability.

Labor Savings and Efficiency Gains

One of the most immediate and measurable benefits of automated material handling is the reduction in manual labor hours. Traditional mulch delivery and installation methods are time-consuming, physically demanding, and require a large crew. With equipment like the Mulch Mule, tasks that used to take a team several hours can now be completed in a fraction of the time with fewer workers. This not only lowers labor costs but also allows teams to complete more jobs per day, increasing billable hours and revenue.

Reduced Equipment Strain and Maintenance

Handling bulk materials manually or with outdated equipment can put significant wear and tear on trucks and machinery not designed for such tasks. Advanced systems like the Mulch Mule are purpose-built, which means less strain on your core fleet and reduced maintenance costs over time. Preserving the longevity of your primary vehicles contributes directly to ROI by extending their service life and reducing repair expenses.

Increased Job Turnover and Capacity

With faster loading, transport, and installation capabilities, automation enables your team to take on more jobs without expanding your workforce. This means you can scale your operations more effectively, accept higher volumes of work during peak seasons, and reduce bottlenecks—all of which lead to improved cash flow and business growth.

Enhanced Quality and Customer Satisfaction

Consistent, professional material placement (like uniform mulch depth and clean job sites) can lead to better outcomes for your clients and fewer callbacks. Happy customers are more likely to become repeat clients and refer your services to others, directly impacting your bottom line and long-term growth.

Reduced Liability and Workplace Injuries

Manual handling of heavy materials increases the risk of workplace injuries, which can result in costly insurance claims, downtime, and reduced morale. Automating these high-risk tasks with equipment like the Mulch Mule helps protect your crew and your business, contributing to both financial and operational stability.

Long-Term Asset Value

High-quality automation equipment retains its value well over time. The Mulch Mule, for example, is designed with durability and resale in mind, which means that even years down the line, it remains a valuable business asset. Whether you plan to use it for a decade or eventually upgrade, it’s an investment with tangible return potential.

While the initial cost of advanced equipment like the Mulch Mule may seem significant, the ROI becomes clear when factoring in labor savings, job efficiency, increased capacity, and reduced liability. For landscaping companies looking to streamline operations and position themselves for growth, investing in automation isn’t just worth it—it’s a competitive advantage.

Embrace Automation for a Competitive Edge

The landscaping industry is evolving, driven by the need for efficiency, safety, and cost-effective operations. Advanced bulk material handling systems offer a practical solution to many of the challenges faced by today’s professionals. By integrating automation into daily practices, businesses can optimize their operations, reduce labor costs, and improve project turnaround times—all while creating a safer, more sustainable work environment.

Tools like the Mulch Mule empower companies to meet the growing demands of the industry, transforming traditional labor-intensive processes into streamlined, efficient operations. Get a quote today and learn how Mulch Mule is well worth the investment for a company looking to grow profitability and scalability. The future of landscaping and construction lies in embracing innovation, and automation is a critical step toward securing a competitive edge in an ever-changing industry landscape.