In the landscaping industry, building a strong safety culture is not just about compliance—it’s about protecting your team, optimizing operations, and fostering long-term success. Landscaping involves physical tasks such as material handling, tree care, mowing, and debris removal. Each task poses challenges like operating heavy equipment, managing hazardous materials, and working in unpredictable conditions. Prioritizing safety is essential for both your team’s well-being and your company’s profitability.

A robust safety culture means embedding safe practices into daily operations. When safety becomes second nature for leadership and crew members, the results are transformative—fewer injuries, reduced costs, higher productivity, enhanced morale, and a better reputation.

This article explores why a safety-focused approach is critical for landscaping businesses and offers practical strategies to tackle hazards, develop a proactive safety mindset, and leverage innovative tools like the Mulch Mule to potentially reduce risks and increase efficiency.

The Importance of Establishing a Strong Safety Culture in Landscaping Companies

Cultivating a safety-oriented mindset goes beyond handing out personal protection equipment (PPE) or scheduling occasional training sessions—it means making safety a core value of your organization.

Balancing Safety and Efficiency

Rather than slowing work, proper safety procedures can reduce downtime caused by equipment failures or injuries. Teams that follow well-designed work practices can complete projects more efficiently and deliver higher-quality results.

Boosting Employee Morale and Retention

Employees who feel safe are more engaged and loyal. Investing in protective equipment—for example, using the right PPE—and thorough training shows that you value their well-being. This not only improves morale but also reduces turnover and the associated training costs.

Building Trust with Clients

A strong safety reputation enhances your company’s public image. Clients are more confident working with companies that maintain safe job sites and consistent practices. High safety standards can lead to repeat business, referrals, and a distinctive competitive advantage.

The Financial and Operational Advantages of Prioritizing Safety in Landscaping

Focusing on safety is an investment that pays off. Beyond the direct costs associated with workplace injuries, there are significant operational and financial benefits.

Lower Workplace Injuries and Insurance Costs

Landscaping jobs often involve risks such as slips, falls, and overexertion. A single accident can result in medical expenses, lost productivity, and higher insurance premiums. By reducing accidents through regular training and proper equipment maintenance, companies can lower claims and keep insurance costs more predictable.

Increased Efficiency and Fewer Delays

Accidents and equipment malfunctions disrupt workflow and delay project timelines. Maintaining strict safety protocols—through regular tool maintenance, clear procedures, and proactive inspections—can minimize these disruptions. A steady work pace not only satisfies clients but also allows companies to take on additional projects.

Enhanced Brand Reputation and Client Trust

A strong safety record helps strengthen your company’s reputation and builds client trust. Companies known for their safe operations are often better positioned to attract more business, benefiting from word-of-mouth referrals and solid market standing.

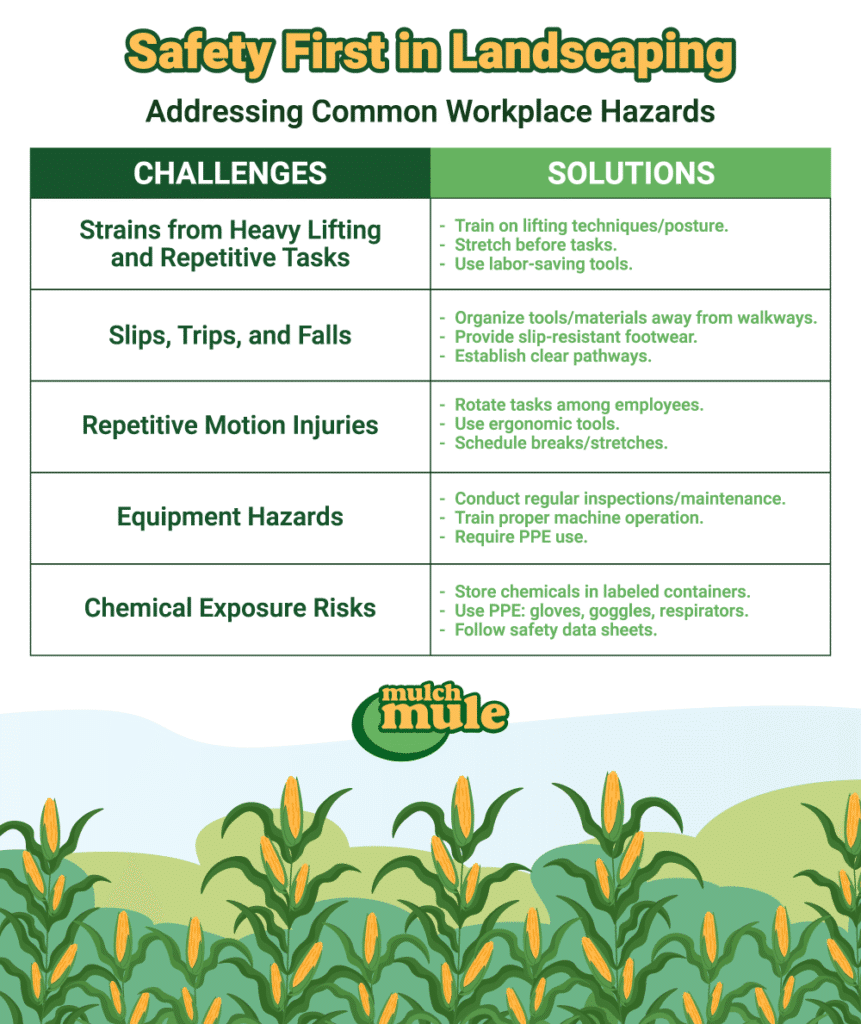

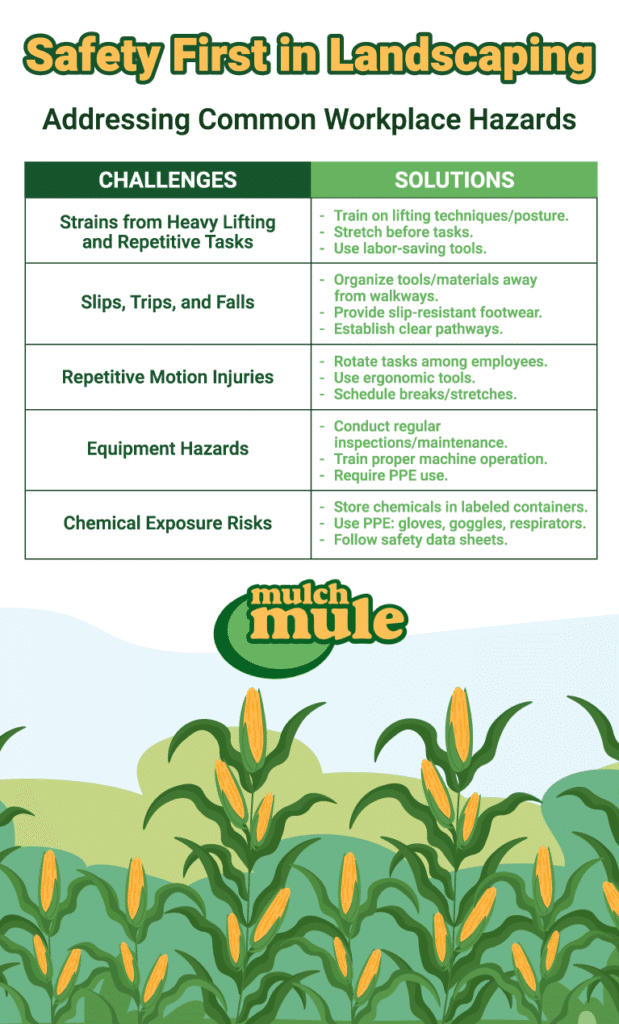

Common Workplace Hazards and How to Address Them

Landscaping work involves several hazards. Addressing these risks with proactive safety measures is essential to creating a secure work environment.

Preventing Strains from Heavy Lifting and Repetitive Tasks

Tasks such as shoveling mulch, moving heavy materials, and raking can lead to muscle strain and long-term injuries. To reduce strain:

- Train workers on proper lifting techniques and posture.

- Encourage stretching before physically demanding tasks.

- Use labor-saving tools like wheelbarrows, mechanized loaders, or advanced material handling systems to ease manual labor.

Reducing the Risk of Slips, Trips, and Falls

Uneven terrain and cluttered work areas can result in falls. To help prevent these incidents:

- Keep tools and materials organized and stored away from walkways.

- Provide slip-resistant footwear.

- Establish clear pathways for transporting materials safely.

Avoiding Repetitive Motion Injuries

Repetitive tasks, such as mowing and trimming, may lead to conditions like tendonitis. Limit these risks by:

- Rotating tasks among employees.

- Using ergonomically designed tools.

- Scheduling regular breaks and incorporating stretching routines.

Managing Hazards from Equipment Use

Improperly maintained machinery poses serious dangers. To enhance safety:

- Conduct regular equipment inspections and maintenance.

- Ensure that employees are well-trained on proper machine operation.

- Require the use of appropriate personal protective equipment when operating machinery.

Minimizing Chemical Exposure Risks

Handling pesticides and fertilizers requires strict adherence to safety protocols to avoid harmful exposure. Best practices include:

- Storing chemicals in properly labeled containers.

- Using PPE such as gloves, goggles, and respirators.

- Following safety data sheets closely and avoiding chemical use in adverse weather conditions.

- Exploring alternatives like using bio-based chemicals can further mitigate environmental risks.

Strategies for Cultivating a Safety-First Culture in Your Landscaping Business

Developing a safety-first mindset involves continuous effort and commitment from everyone in the organization.

Lead by Example

When leadership consistently follows safety protocols—such as wearing proper PPE and adhering to guidelines—employees are more likely to follow suit. Modeling best practices sets a company-wide standard that underscores the importance of safety in every task.

Deliver Ongoing Safety Training

Safety training should be a continuous process rather than a one-time event. Regular training sessions, including hands-on demonstrations, ensure that employees remain updated on the latest protocols and equipment handling techniques. Refresher courses are crucial in reinforcing best practices and adapting to new safety challenges.

Perform Routine Audits and Site Inspections

Regular site inspections and equipment audits can help identify potential hazards before they lead to accidents. Using checklists and involving employees in safety reviews enhances overall vigilance, allowing for timely interventions and adjustments.

Foster Open Communication

Encourage workers to report hazards or near misses without fear of reprisal. Establish clear channels—be it through daily briefs, suggestion boxes, or regular safety meetings—for employees to provide feedback. This transparency builds trust and reinforces a collective commitment to safety.

Recognize and Reward Safe Practices

Acknowledging employees who consistently follow safety protocols can serve as positive reinforcement. Whether through public recognition or incentive programs, celebrating safe work practices encourages everyone to uphold high safety standards.

Leveraging Innovative Equipment for Safer Operations

Modern landscaping equipment plays a key role in reducing physical strain and enhancing safety in the workplace.

Advancing Safety Through Equipment Design

Today’s landscaping machinery is engineered with both efficiency and operator safety in mind. Innovations such as vibration-reducing platforms, lightweight battery power, and ergonomic designs are intended to reduce fatigue. These features help minimize operator exposure to various hazards, contributing to a safer work environment on site.

Benefits of Automation in Hazardous Tasks

Automation in landscaping minimizes reliance on manual labor for strenuous tasks. Automated systems for loading and unloading materials can reduce the physical strain on workers, allowing teams to focus on tasks that require precision rather than heavy lifting.

Year-Round Safety and Labor Optimization

Investing in versatile, automated equipment enables companies to sustain safe operations throughout the year. Multipurpose machinery can handle a variety of tasks across different seasons, reducing reliance on manual labor and ensuring consistent productivity and safety regardless of seasonal challenges.

Innovative Machinery: Mulch Mule’s Revolutionizing Role in Landscaping Safety and Efficiency

The Mulch Mule stands out as a groundbreaking piece of equipment, demonstrating how thoughtful engineering can significantly enhance safety and operational efficiency for landscaping businesses. This machinery integrates advanced safety features and labor-saving capabilities that fundamentally reshape the approach to landscaping tasks. Here’s how:

- Streamlined Loading and Unloading: The live-floor system of the Mulch Mule revolutionizes the handling process by automating the loading and unloading of materials. This reduction in manual labor minimizes physical strain and decreases the risk of injuries related to repetitive shoveling.

- Enhanced Flexibility with Curbside Discharge: Equipped with optional curbside discharge capabilities, the Mulch Mule facilitates direct material distribution without needing manual intervention on precarious grounds. This allows workers to maintain a safe distance from heavy loads, reducing the likelihood of accidents.

- Remote-Operated Vacuum Loader: The inclusion of a remote-operated vacuum loader exemplifies Mulch Mule’s commitment to a safer working environment. This feature enables workers to manage tasks from a secure vantage point, avoiding potential risks associated with close proximity to moving machinery.

- Cleaner and Safer Workspaces: By minimizing spillage and regulating material flow, this equipment keeps work areas systematically organized and free of clutter. A clean workspace inherently mitigates risks such as slips, trips, and falls.

Click on the video below to hear from Isaiah Brazytis with Leafstone Landscape’s. He tells us why they love their Mulch Mule and what it has done for their company.

The Mulch Mule’s innovative features collectively create a safer and more productive landscape working environment. By reducing manual labor and enhancing operational safety, companies not only protect their workforce but also elevate their service quality and competitive edge in the industry.

Overcoming Labor Challenges While Enhancing Safety and Productivity

In today’s market, labor shortages and rising wages mean that efficiency and safety have never been more important. Smaller teams must often compensate by achieving more with available resources.

Addressing Labor Shortages with a Safety-First Approach

A commitment to safety can make your company more attractive to skilled workers. Teams that feel secure and valued are more likely to remain with a company that invests in modern, safe equipment. This approach not only helps in recruiting but also in retaining experienced workers, reducing the costs associated with high turnover.

Empowering Smaller Teams with Smarter Solutions

In circumstances where labor is limited, maximizing the productivity of each worker is crucial. Advanced equipment, such as automated material handlers, can reduce the physical demands on employees. Features designed for rapid and precise material handling aid small crews in maintaining productivity while upholding high safety standards.

Supplementing Safety Through Regulatory Guidance and Demonstrations

In addition to in-house best practices, industry standards help companies stay on track. Following OSHA’s landscaping safety guidelines provides a solid foundation for hazard assessment, equipment operation, and employee training. Regularly consulting these guidelines can highlight potential gaps in your current safety approach, paving the way for continuous improvement in landscaping safety procedures.

Hands-on demonstrations further elevate safety training. Live demos let workers observe proper techniques, spot equipment issues proactively, and practice safe habits in realistic scenarios. For example, Mulch Mule’s Ambassador Program enables potential buyers or new teams to see the Mulch Mule in action. By connecting with an Ambassador, you can witness firsthand how automated discharge, vacuum loading, and user-friendly controls reduce manual labor and keep workers out of harm’s way.

Through both regulatory adherence and practical demonstrations, landscaping crews learn how to combine the latest equipment advantages with recognized safety standards, enhancing productivity without compromising well-being.

Emerging Trends and Future Innovations in Landscaping Safety

As technology and industry practices evolve, new trends are shaping the future of landscaping safety. Many companies are exploring how the smart use of eco-friendly tools can boost operational efficiency while reducing environmental impact. Alternatives like bio-based chemicals are also gaining traction as a safer option.

Enhanced online resources, including simulation-based learning platforms, are becoming integral to modern safety programs. As the industry grows more tech-driven, these innovations—combined with a steadfast commitment to safety—position landscaping businesses for long-term success.

Moving Forward with a Safety-Driven Landscaping Business

Creating a safety-first culture is essential for landscaping companies to reduce risks, boost workflow efficiency, and build a resilient workforce. By addressing common hazards—such as heavy lifting, repetitive tasks, and equipment-related injuries—and implementing ongoing training and regular safety audits, companies can effectively protect their teams while maintaining high operational standards.

Innovative solutions highlight how modern equipment can contribute to a safer work environment by automating labor-intensive tasks and reducing physical strain. Investments in such technologies not only safeguard employees but also enhance your company’s reputation and long-term success.

Take the next step in protecting your team and optimizing your operations by watching more testimonials to see first-hand how Mulch Mule has elevated the safety culture and the employee morale in landscaping businesses just like yours.