Transporting loose materials like mulch, soil, or stone requires meticulous planning and the right techniques to ensure safety. Unlike solid, compact cargo, these materials can shift and flow during transit, straining equipment, affecting vehicle handling, and increasing the risk of tipping or spills. Hazards such as spills, unstable loads, or dust exposure can jeopardize worker well-being, delay projects, and create costly liabilities. For landscaping professionals, incorporating proven safety strategies is vital to protect crews, maintain productivity, and safeguard profitability.

This guide explains the challenges of bulk material transport, offers actionable tips for safer practices, and highlights equipment innovations that optimize secure, efficient workflows. Safety isn’t only about regulations—it’s an investment in smoother operations, team morale, and long-term returns.

Recognizing Bulk Material Behavior on the Road

Loose materials can behave unpredictably once you’re in motion. Understanding these behavioral tendencies helps you better plan for and control potential risks.

Key Traits of Bulk Materials

- Shifting loads: During braking or cornering, materials can move like a liquid, causing imbalance and strain on containment. Adopting automated material handling equipment can help reduce these risks.

- Settling: Vibrations and bumps can compress or redistribute materials, creating voids that allow further movement.

- Variable weight: Moisture levels alter overall mass, influencing trailer stability.

- Pressure on containment: Dense loads place significant force on trailer walls, underscoring the importance of robust construction.

Challenges with Poor Load Management

When materials are mismanaged or overloaded, imbalance occurs, leading to spills, trailer strain, and even operational shutdowns. Uneven weight distribution can make steering and braking unpredictable, accelerate wear on axles and suspension components, and increase the likelihood of equipment damage. In severe cases, operators may face citations, injury risks, and unplanned downtime while loads are cleaned up or equipment is repaired. Images of trucks tipping or trailers spilling illustrate the real dangers of neglecting secure loading.

Preparing Trailers and Loads for Safe Transport

Preventative measures taken before hitting the road significantly reduce hazards. Inspections and strategic loading play essential roles.

Conducting Pre-Trip Inspections

A thorough pre-trip check ensures your trailer and towing vehicle are road-ready. Key points include:

- Tires: Confirm proper inflation and tread health.

- Trailer structure: Look for damage, worn flooring, and compromised sidewalls.

- Lights and hitch connections: Verify functionality and secure couplings.

- Capacity compliance: Confirm load weight is within the trailer’s weight capacity.

- Final checks: Use established pre-trip inspections protocols to ensure everything is in top condition.

Optimizing Loading Techniques

How you load bulk materials directly affects trailer stability, handling, and overall safety. Start by understanding how the material behaves, then place it to keep the load balanced and contained.

- Know your material: Identify key characteristics such as moisture level, density, and particle size so you can anticipate how it will settle or shift.

- Distribute weight correctly: Spread material evenly side-to-side and bias heavier weight toward the front of the trailer (within safe tongue-weight guidelines) to improve stability.

- Use a layering strategy: Place denser, heavier materials at the bottom and lighter materials on top to reduce movement and settling issues.

- Respect capacity limits: Avoid overloading. Excess weight can strain frames, axles, and brakes, and increase the risk of structural or handling problems.

- Reinforce containment: Use secure containment features such as high sidewalls and sealed gates to limit lateral and vertical movement.

- Double-check before departure: Reassess containment, weight distribution, and overall load security before heading out, and adjust loading and driving strategies for seasonal conditions like wet, frozen, or very dry materials.

Tie-Downs and Load Security Techniques

Secure tie-downs and load restraints prevent accidental spills and protect everyone on the road.

Tools for Securing Loads

Effective load security might include:

- Tarp systems or covers to reduce dust and spillage

- Sealed tailgates to minimize material loss

- Tall, reinforced sidewalls for greater containment

- Partitions to separate equipment from bulk materials

Combining Bulk Materials and Equipment

If hauling equipment simultaneously:

- Secure non-bulk items first with straps or chains.

- Use partitions so materials won’t shift into other cargo.

- Finish by layering bulk materials, ensuring they don’t block tie-down points.

Best Practices for Load Security

- Inspect belts, chains, or tarp systems regularly.

- Spread weight evenly to reduce concentrated stress points.

- Stop periodically on longer hauls to confirm stability.

- Utilize high-quality tie-downs for reliable fastening.

- Emphasize robust load security methods throughout.

Preventing Spills During Transport

Spills risk worker safety and prompt costly cleanup. Even small spill events can disrupt schedules and compromise your professional reputation.

Common Causes of Spills

- Overloading beyond capacity

- Damaged or loosely latched tailgates

- Poor weight distribution

- Sudden stops or turns

- Mechanical failures due to inadequate maintenance

Best Practices for Spill Prevention

- Respect capacity limits for the trailer.

- Double-check all gates and latches.

- Maintain balanced loading – avoid placing too much weight on one side.

- Drive cautiously and employ defensive driving techniques.

- Inspect equipment regularly to catch worn parts before failure.

Dust Control for Bulk Materials

Dust is more than just a minor annoyance. In bulk material transport, it can obscure vision, pose respiratory risks, and damage client relationships.

Why Dust Control Matters

- Protects driver visibility

- Shields workers from airborne hazards

- Preserves professionalism on-site

- Helps comply with evolving health and safety regulations

Strategies for Dust Management

- Pre-wet dusty materials before loading

- Secure tarps or cover systems to contain dry particles

- Reduce speed and avoid abrupt movements that stir up dust

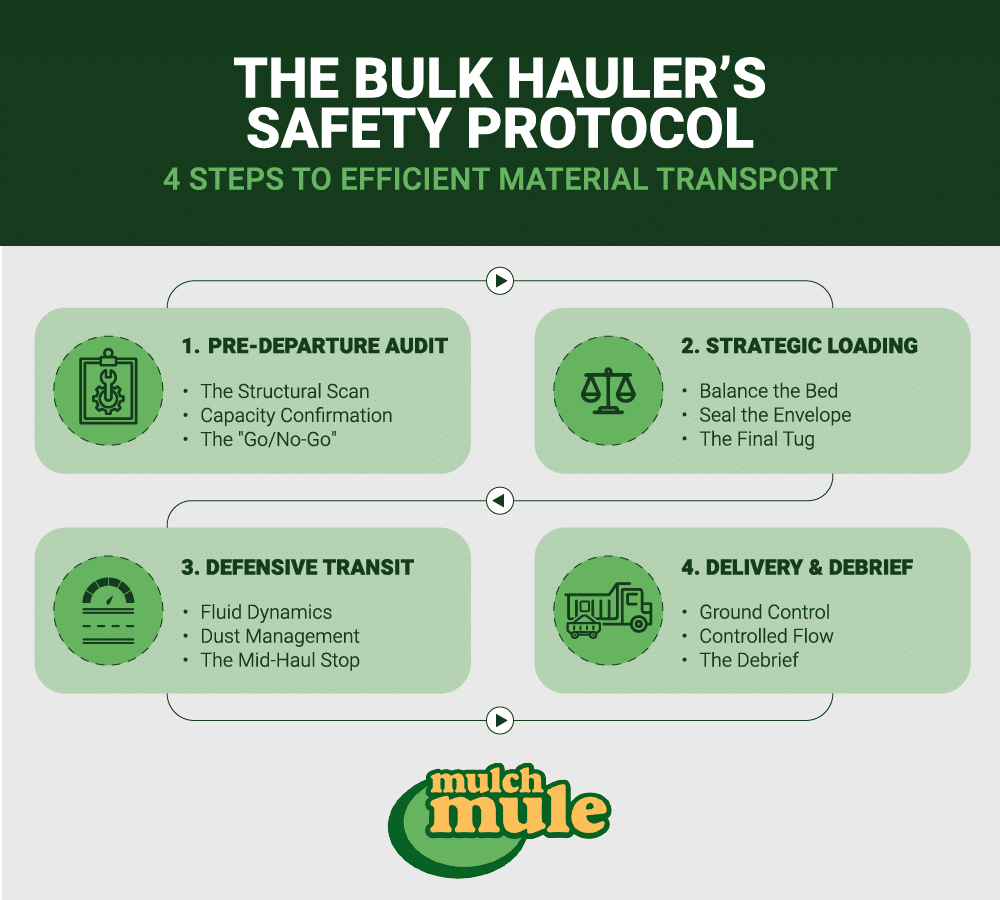

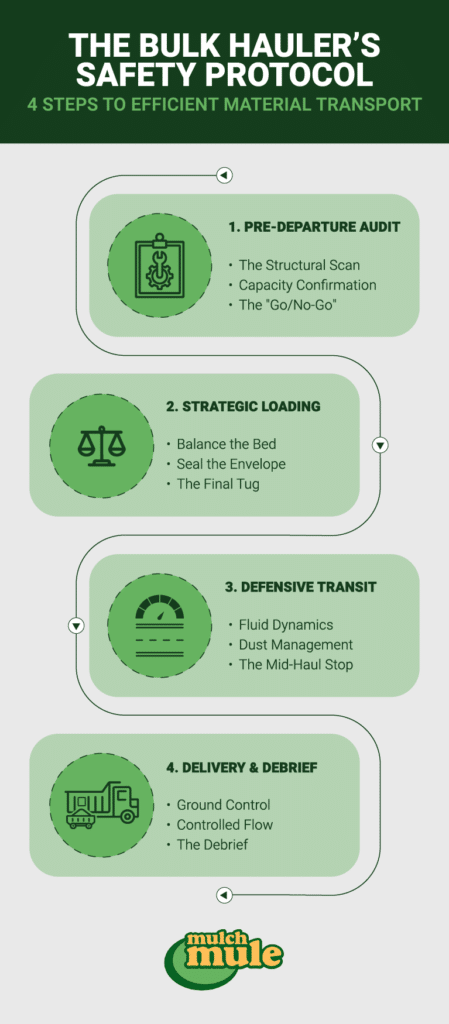

Creating a Safe and Efficient Transport Workflow

Safe habits throughout each phase—from pre-trip to post-trip—elevate overall efficiency and reduce accidents.

Pre-Trip Checklist

Before transport, follow your standard pre-trip inspection (tires, lights, structure, capacity, and final checks) outlined above.

Loading and Securement

During loading and securement, apply the safe loading, containment, and tie-down practices outlined above to maintain even weight distribution, stable containment, and a fully secured load before departure.

In-Transit Practices

- Employ defensive driving to minimize load shifts.

- Periodically check load security during long journeys.

- Adjust speed to reduce dust generation and the strain on containment systems.

Unloading and Post-Trip Review

- Choose stable, level ground for controlled unloading.

- Utilize techniques such as live floor systems or directional unloading for precision.

- Conduct a post-trip inspection to identify any equipment wear or damage.

- Document observations to refine future transport strategies.

Comprehensive Crew Training and Regulatory Compliance

Even the best equipment and pre-trip routines can fall short if teams are not adequately trained or if regulations are misinterpreted. Investing in comprehensive crew training and remaining compliant with applicable guidelines ensures a safer work environment.

Comprehensive Crew Training

Training extends beyond just learning how to load a trailer. It involves practical hands-on demonstrations, ongoing refreshers, and well-documented procedures so every team member understands their role. Key training elements include:

- Hazard Communication: Teach workers to identify risks such as unbalanced loads, unsecured materials, or faulty tie-downs.

- Job Hazard Analysis (JHA): Encourage regular assessments before tasks begin to identify potential dangers.

- Safety Briefings: Short, focused discussions on equipment handling, dust control, and spill prevention before shifts.

- Cross-Training: Train all crew members on operating trailers, loading, securing materials, and performing pre-trip inspections to maintain operations if key personnel are unavailable.

- Cultivating a Safety Culture: Foster an environment where employees feel empowered to report potential issues without fear of repercussions.

By blending hands-on training with detailed written procedures, companies can reduce accidents, maintain compliance, and boost crew morale and productivity.

Navigating District and Federal Regulations

Compliance with regulations can differ across state lines, counties, or even local jurisdictions. Staying informed about weight restrictions, trailer guidelines, and seasonal transport rules is essential. Typical regulatory concerns include:

- Department of Transportation (DOT) Requirements: Ensure vehicles meet all mandatory standards, including weight limits and brake inspections.

- Special HAZMAT Rules: While mulch and soil are not classified as hazardous, certain additives may trigger hazardous material regulations.

- CDL Regulations: Operators of vehicles with heavy loads or large trailers might need a Commercial Driver’s License as mandated by state or federal law.

- Local Ordinances: Some regions impose noise restrictions or special dust control requirements, especially near residential areas or conservation zones.

Proactive regulatory compliance not only avoids fines but reinforces your reputation as a responsible service provider.

Key Trailer and Containment Features for Safer Bulk Transport

Standard tie-downs often aren’t sufficient for loose materials. The right trailer design and rugged containment features can substantially enhance the safety of your material transport operations by preventing spills, stabilizing loads, and supporting controlled unloading.

Key features to consider include:

- Enclosed designs or sealed tailgates to reduce material loss and accidental discharge.

- Elevated or tall, sealed sidewalls to reduce spill risks and better contain loose, lightweight materials.

- Live floor systems for smoother, safer unloading and a steady, even flow of material.

- Forward or reverse directional discharge setups to improve control over where and how material is placed.

- Hydraulic stabilizers to keep trailers level and stable during offloading.

- Integrated tarp solutions to reduce spillage and dust.

- Robust construction to support year-round use and withstand the demands of bulk material hauling.

Well-engineered containment and trailer features prevent lateral and vertical load shifts, safeguard the trailer and its cargo, and contribute to improved handling and efficiency. Innovative trailer designs—such as those incorporated into the Mulch Mule trailer—can play a key role in creating safer, more reliable bulk transport workflows.

Seasonal and Year-Round Bulk Hauling Considerations

Seasonal changes can drastically alter how bulk materials behave and how safely they can be transported. Adjusting your loading, containment, and driving strategies throughout the year helps keep crews safe and jobs on schedule.

Winter

- Snow and ice can increase load weight unpredictably and reduce traction.

- Allow for longer stopping distances and slower speeds.

- Verify that tires, brakes, and lights are winter-ready.

- Clear snow and ice from loading, unloading, and walking surfaces to reduce slip hazards.

Spring

- Rain-soaked mulch, soil, and debris are significantly heavier and more prone to shifting.

- Monitor moisture content and confirm that loads remain within rated capacity.

- Use tarps or covers to limit additional water absorption in transit.

- Check containment systems and tailgates for leaks before hauling.

Summer

- Dry conditions increase dust generation, which can impair visibility and create respiratory concerns.

- Prioritize dust control measures: pre-wet materials where appropriate and use tarp systems or covers.

- Reduce speed on unpaved or uneven surfaces to minimize dust and material agitation.

Fall

- Lightweight debris such as leaves and yard waste is easily lifted by wind.

- Use higher sidewalls, sealed tailgates, and secure tarps to prevent blowouts.

- Pay attention to crosswinds and adjust driving behavior accordingly.

Year-Round Equipment and Operational Practices

- Regularly inspect trailers for structural integrity, including floors, sidewalls, and tailgates.

- Keep hydraulic systems, electrical components, and connections protected from moisture and corrosion.

- Use fluids and lubricants rated for the temperature ranges in your operating region.

- Update crew training and standard operating procedures to reflect seasonal changes and recurring lessons learned.

Adapting your approach according to seasonal conditions—and updating both equipment and training as you go—ensures your bulk hauling operations stay safe, efficient, and reliable all year long.

Frequently Asked Questions

What is the safest way to secure mulch in a trailer?

Use a purpose-built bulk trailer with tall or enclosed sides, sealed tailgates, and a properly rated hitch. Load mulch evenly, biasing weight slightly toward the front (within tongue-weight and axle limits), then secure the load with a tight-fitting tarp or cover to prevent blowout and dust. Perform a quick walk-around before departure to confirm gates, latches, and covers are fully closed.

How much can I load in a mulch trailer without overloading?

Never exceed the lowest of these three ratings: the trailer’s GVWR, the axle ratings, or the tow vehicle’s towing capacity. Remember that wet mulch can weigh significantly more than dry mulch, so factor moisture into your estimate. When in doubt, underload slightly and make an extra trip instead of risking unsafe handling, fines, or equipment damage.

Do I need a CDL to haul bulk landscaping materials?

You may need a Commercial Driver’s License (CDL) if the combined weight of your truck and trailer exceeds federal or state thresholds (often 26,001 lbs GVWR or higher), regardless of whether the material is “hazardous.” Requirements vary by state and by how your business is classified. Always confirm with your state’s Department of Transportation or licensing agency for current rules.

How do live floor trailers improve bulk material safety?

Live floor trailers unload material using a moving floor instead of raising the bed, which lowers the risk of tipping on uneven ground. They allow for more controlled, even discharge, reducing sudden surges of material that can cause spills or unstable piles. This makes them especially valuable on tight jobsites and for crews unloading frequently throughout the day.

What are the best dust control methods for mulch transport?

Pre-wet excessively dry mulch when appropriate, then cover the load with a tarp or integrated cover system to keep particles contained. Drive at moderate speeds—especially on gravel or unpaved roads—to reduce agitation and dust clouds. Maintaining good containment (tight sidewalls, sealed tops, and tailgates) also helps minimize dust and debris leaving the trailer.

Elevating Your Bulk Transport Safety Strategy

Effective bulk material transport safety is crucial for smooth, reliable operations. By understanding how loose materials behave, rigorously inspecting equipment, securing loads meticulously, and adopting defensive driving strategies, you can protect your workforce and equipment from unnecessary risks.

Ready to improve your transport operations? Mulch Mule offers innovative equipment engineered for year-round safety and efficiency. Schedule a live demonstration through the Mulch Mule Ambassador Program to discover how these advanced solutions can streamline your bulk material handling today.