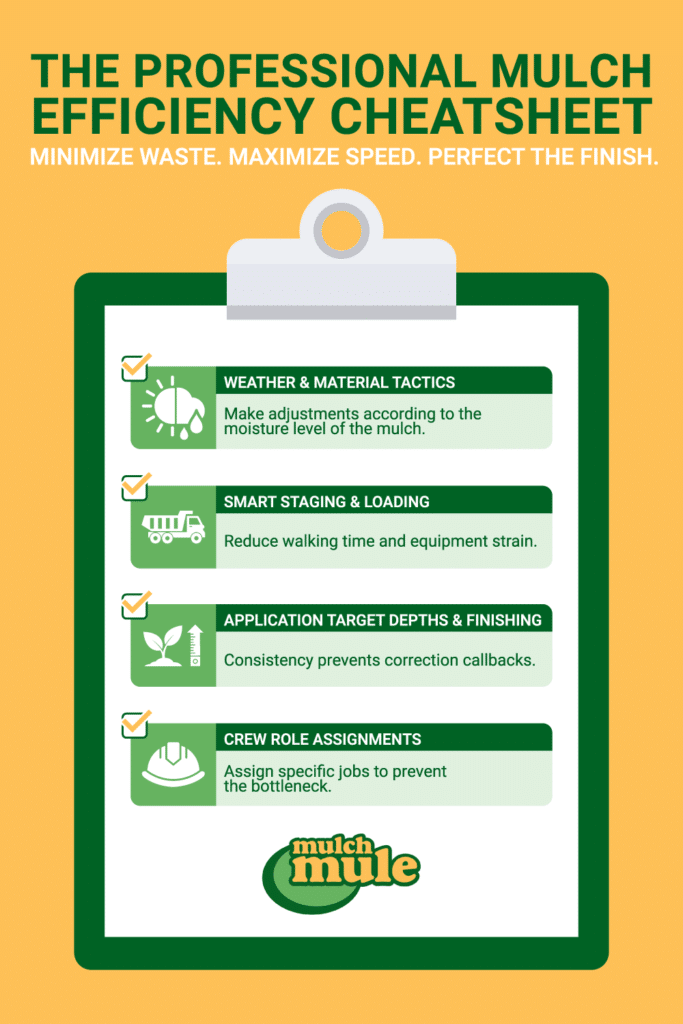

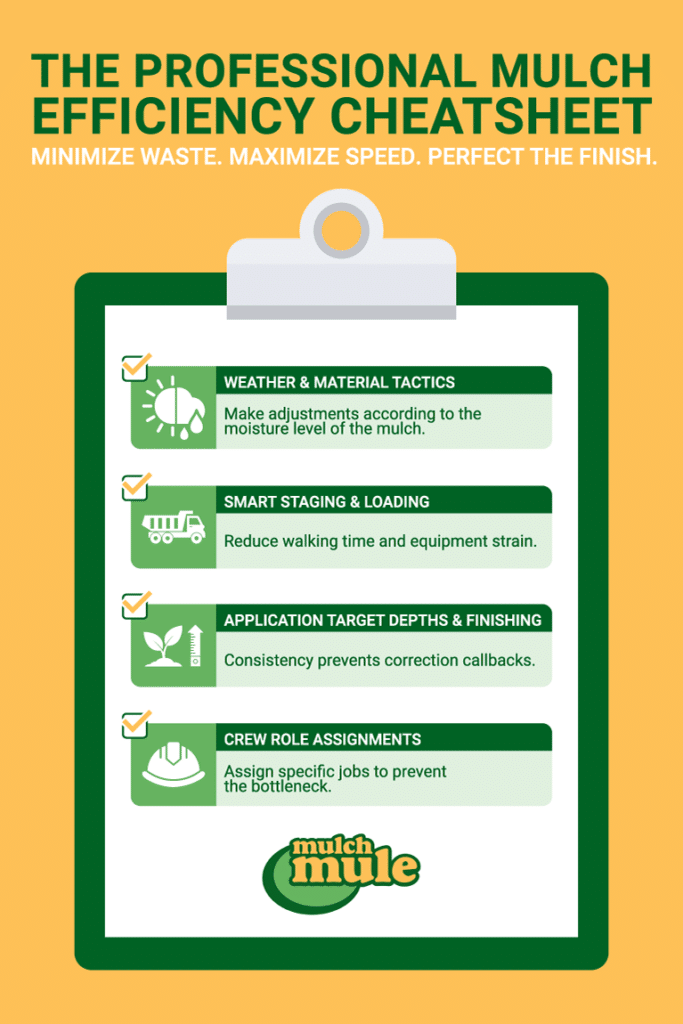

Efficient mulch handling is critical for professional landscapers who want to maximize productivity while delivering consistent, high-quality results. Done right, mulch improves soil health, suppresses weeds, and elevates curb appeal—but factors like moisture content, material volume, clumping, and spillage can quickly slow crews down and drive up labor costs. Professional mulch application requires more than simply dumping material into beds; it depends on smart loading, transport, and discharge techniques that ensure even coverage and the right depth every time.

By refining your processes and using purpose-built equipment, you can streamline operations, reduce waste, protect your crew and machinery, and maintain the standards your clients expect. This guide walks through practical best practices—from handling wet vs. dry mulch to optimizing equipment settings and crew workflows—so your team can complete mulch jobs faster, more efficiently, and with a better finish on every site.

What Slows Down Mulch Jobs (and Cuts Into Your Profits)

- Moisture issues: Wet mulch clumps and bridges in equipment; dry mulch blows away and needs rework.

- Excess hand labor: Too much shoveling and wheelbarrow time leads to fatigue and lower daily production.

- Poor staging: Mulch piles placed too far from work areas or in tight, awkward spots add unnecessary walking and maneuvering.

- Inconsistent depth and coverage: Uneven spreading creates callbacks and extra cleanup.

- Equipment downtime and clogs: Incorrect settings or overloaded trailers stall crews and eat into margins.

Understanding Mulch Behavior: Wet vs Dry

Optimizing mulch handling begins with understanding its behavior under different conditions. Mulch may be wetter or drier depending on storage and weather, and each state affects handling differently.

Wet Mulch: Considerations

Wet mulch is heavier and more prone to clumping. Its natural density helps it remain in place once spread but can make loading less efficient. Adjusting equipment settings—such as reducing discharge speed—and blending wet mulch with a drier batch can help prevent clumping and ease movement. This method minimizes strain on both equipment and crew while ensuring that the mulch retains sufficient cohesion to protect plant roots effectively.

Dry Mulch: Considerations

Dry mulch is lighter and spreads quickly, but it can scatter in windy conditions, resulting in uneven coverage and wastage. To counter these issues, maintain a low, controlled spread close to the ground by using steady discharge techniques and operating during calmer weather. Employing targeted spreading tools and, where appropriate, temporary wind barriers further helps to reduce material loss.

Adapting Your Strategy

Tailor your approach based on the mulch’s moisture condition. Evaluate conditions before beginning a job, communicate the differences clearly to your crew, and adjust equipment settings—such as discharge speeds and angles—accordingly. This proactive strategy reduces waste, helps ensure uniform coverage, and safeguards your equipment.

Best Practices for Loading and Transporting Mulch

Efficient staging, loading, and transporting of mulch lay the foundation for a consistent spread, ensuring that the material is handled precisely throughout the process.

Staging the Jobsite

Establish an organized staging area for mulch piles, preferably on level ground away from busy zones. A well-prepared staging area minimizes unnecessary movement, improves safety, and simplifies the transition from storage to trailer loading. Designate specific zones for different materials to avoid mix-ups on larger job sites.

Optimizing Load Distribution

Even load distribution in the trailer is essential. Spread the mulch evenly across the trailer floor to promote balance and facilitate smooth discharge. When dealing with wet mulch, alternating layers helps to reduce dense clumps. Avoid overloading the trailer to maintain safety, reduce equipment wear, and preserve the beneficial properties of the material.

Securing Loads

After loading, secure the mulch with tarps or cover systems to prevent spillage during transport. Regular inspections during transit and prior to discharge help maintain operational efficiency and ensure that material is not lost—which in turn reduces costs.

Techniques for Achieving High-Quality Mulch Spreading

Delivering a professional finish with mulch involves controlling both depth and distribution while attending to aesthetic details.

Determining Ideal Mulch Depth

Aim for a mulch layer of two to three inches in flower beds to gently insulate plant roots and up to four inches in areas prone to heavy traffic or erosion. In shaded regions, thinner layers may be preferable to avoid restricting water penetration, while sunlit areas can benefit from a thicker application. Maintaining accurate depth enhances the visual appeal and supports plant health in line with established horticultural practices.

Achieving Even Coverage

Uniform distribution is the hallmark of quality work. Automated spreaders with adjustable settings can help achieve consistency, while manual methods benefit from methodical raking and redistribution. Depositing small, controlled piles and then smoothing them out can help secure even coverage across the area.

The Finishing Touch

After spreading, use a stiff rake to even out any patches and sharpen the edges around trees, shrubs, and flower beds. This final step not only improves the appearance of the landscape but also prevents mulch from accumulating excessively against plant trunks—a situation that can lead to moisture retention and potential rot.

Adjusting Workflow for Wet vs Dry Mulch

Tailoring workflows to match the mulch’s condition is crucial for maintaining both efficiency and quality.

Managing Wet Mulch

For wet mulch, slowing the discharge process helps avoid clumping while allowing for a controlled spread. Integrate additional steps to break apart clusters during unloading, and consider transporting lighter loads more frequently to minimize mechanical and operator fatigue. Adjust equipment settings proactively based on the material’s density to achieve uniform discharge while protecting machine components.

Handling Dry Mulch

For dry mulch, adopt shorter, methodical spreading movements to prevent dispersal by wind. Automated curb-side discharge systems can deposit mulch precisely where it is needed, and scheduling work during calmer weather conditions further enhances spread accuracy. These strategies reduce inconsistencies in material distribution and keep the job site looking well-kept.

Optimizing Equipment Settings

Monitor equipment settings consistently, making adjustments based on whether the mulch is wet or dry. Fine-tuning discharge speeds, spread angles, and calibrating automated systems is essential to minimize waste and ensure consistent job quality. Training crews to recognize and adapt to these adjustments not only preserves material but also fosters operational excellence.

Using Mulch Mule Features to Boost Productivity

Integrating advanced landscaping equipment such as the Mulch Mule trailer can significantly enhance your mulch handling process. The following features are designed to boost efficiency while reducing manual labor:

High-Capacity Hopper

The Mulch Mule trailer features an impressive hopper engineered to carry large volumes of mulch, which in turn reduces the number of trips needed for transport. This not only conserves fuel and time but also decreases equipment and labor wear.

Live Floor System

A key innovation, the live floor conveyor system, facilitates consistent and controlled mulch discharge. Though specific efficiency gains vary by job, many users report that automated systems can help reduce the time spent on mulching tasks—sometimes saving close to an hour or two per site visit. While individual results may vary, automating repetitive tasks has the potential to yield significant labor savings and improved job site management.

Curb-Side Discharge Capability

The curb-side discharge system enables precise deposition of mulch, and is primarily used to fill wheelbarrows even in challenging or crowded spaces. This capability reduces the need for later rework and helps maintain safety by minimizing manual handling near high-traffic areas.

Remote Control Operation

The optional wireless remote control on the Mulch Mule operates the floor functions, allowing operators to discharge material directly into equipment such as a skid steer or mulch buggy without having to get off or out of the machine. This streamlines the loading process, improves safety, and increases efficiency, as operators can control dispensing from their seat.

Year-Round Versatility

The robust design of the Mulch Mule is intended to perform reliably across multiple seasons. Beyond moving mulch, the equipment is also suited to handle soil, leaves, and other materials. This versatility supports both routine maintenance and more specialized landscaping tasks throughout the year.

Real-World Example

Keegan Minard, the owner of Minards Landscape, put the Mulch Mule to work in real jobsite conditions—and saw the difference it makes in both speed and quality. Instead of relying on manual handling, their crew was able to load, transport, and discharge mulch more efficiently, cutting down on wasted motion and fatigue while achieving cleaner, more consistent beds. Before Mulch Mule they were typically doing 50 to 80-90 yards a mulch a day. Since purchasing the equipment they are seeing double the productivity with the same amount of workers. When you combine smart workflows with purpose-built equipment, you don’t just move mulch—you transform how your entire crew operates. Click the video below to hear how the right trailer can turn a labor‑heavy task into a streamlined, repeatable system that supports higher profitability and better results for every project.

Building Repeatable Systems and Training Crews

Establishing standardized workflows and comprehensive training protocols is vital for consistent, safe, and efficient mulch handling.

Defining Crew Roles

Clearly assign responsibilities within the team:

- Crew Leader: Oversees safety and ensures adherence to protocols.

- Trailer Operator: Manages equipment settings and controls material handling.

- Spreaders and Finishers: Focus on achieving uniform spread and clean edge definition.

- Debris Handler: Responsible for cleanup and routine maintenance.

Effective training is essential, and industry observations suggest that comprehensive equipment training plays an important role in bolstering employee retention and job satisfaction. While direct statistics are not always cited, a well-trained crew is more likely to operate efficiently, reduce mistakes, and contribute to an overall positive work environment.

Comprehensive Equipment Training

Regular training sessions familiarizing crews with specialized systems and attachments, such as those on the Mulch Mule, are crucial. Practical demonstrations covering adjustments of discharge speeds, handling of clogs, and routine maintenance underscore the importance of keeping equipment operating at peak efficiency. Comprehensive training not only improves performance but can also help reduce turnover rates and foster professional growth within the crew.

Standardizing Workflows

Implement standardized checklists that encompass:

- Site condition evaluations.

- Organized staging area setup.

- Strategic positioning of equipment.

- Clear role assignments and plan reviews.

- Controlled material discharge with periodic quality checks.

- Thorough cleanup protocols.

Consistent workflows minimize errors and enhance productivity, ensuring quality results across projects.

When It’s Time to Upgrade Your Equipment

Older or overworked tools can impede productivity. Recognize the signs that it might be time to invest in new equipment:

- Frequent breakdowns or long repair times.

- Recurring issues like clogs or erratic material discharge.

- Rising labor costs resulting from increased manual handling.

- Constraints in scaling operations for larger projects.

- Consistent delays in meeting deadlines or servicing challenging terrains.

Upgrading to state-of-the-art equipment such as the Mulch Mule trailer can reduce manual tasks, enhance overall safety, and contribute to more consistent job outcomes. Modern equipment not only streamlines current operations but also positions your business favorably for future growth.

Elevate Your Mulch Handling to New Heights: Start Your Upgrade Journey Today

When you dial in how you move mulch—staging piles correctly, adjusting for wet vs. dry material, standardizing crew roles, and leveraging purpose-built equipment—you get faster jobs, less manual labor, a cleaner finished product, and stronger margins on every project.

If you’re ready to move more yards in less time and give your crews the tools they need to perform at a higher level, now is the time to upgrade. Embrace the benefits of advanced material-handling technology and proactive crew training, and see how these improvements can pave the way for a more profitable future. Contact Mulch Mule today for a live demonstration and take the first step toward transforming your mulch handling operations.