Live floor trailers are a game-changing innovation in bulk-material handling. Unlike traditional dump trailers that rely on tilting the bed to unload materials, live floor systems use hydraulically powered slats to move materials smoothly and efficiently. This design offers a safer and more controlled method of loading and unloading, eliminating tipping hazards and providing precision material placement.

For professionals in landscaping, lawncare, construction, and property management, live floor trailers minimize labor requirements, reduce costs, and boost productivity, directly impacting profitability. By automating heavy lifting, these trailers allow teams to handle materials like mulch, soil, debris, stone, and aggregates with remarkable ease.

In this article, we explain how live floor trailer systems work, highlight their core features, and discuss their benefits across various industries. We also provide guidance on how to get started with a live floor trailer system and explore how Mulch Mule’s innovative equipment can transform material management.

Live Floor Trailer Systems for Bulk-Material Handling

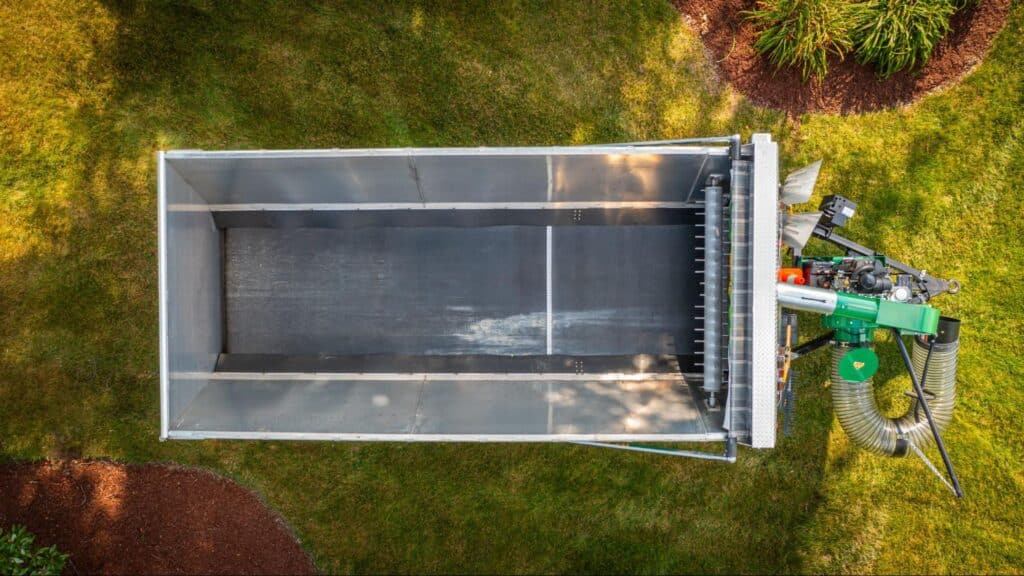

A live floor trailer system is engineered to transport and unload bulk materials with efficiency and precision. Unlike dump trailers that tilt to empty their contents, live floor trailers use a hydraulically powered floor that moves materials horizontally. This method not only enhances safety by preventing tipping but also improves control during unloading.

Industries such as landscaping, lawncare, construction, and property management benefit from this approach through reduced physical strain on workers and time savings on every job. With live floor trailers, handling materials becomes streamlined, lowering labor costs and boosting overall productivity.

How Live Floor Trailers Work to Streamline Operations

Live floor trailers employ hydraulically powered slats integrated into the trailer’s bed, which move in a synchronized sequence to shift materials horizontally. This mechanism eliminates the need to tilt the trailer bed, providing a stable and controlled unloading process.

Forward and Reverse Motion for Precision

The system’s ability to move materials with forward and reverse motion offers exceptional control. Operators can discharge materials evenly or reverse the slats for quick adjustments, ensuring precise placement in tight spaces or on uneven terrains.

Streamlined Loading and Unloading

Materials are loaded onto the trailer much like with traditional methods. During unloading, instead of tilting a heavy bed, the hydraulic system activates the floor slats, methodically advancing materials out of the trailer. This process maintains stability and promotes a smooth material flow even on irregular ground surfaces.

Remote-Controlled Operation

Many live floor trailers feature remote-controlled operation, allowing operators to adjust speed and direction safely from a distance. This remote operation enhances safety and precision, ensuring materials are placed exactly where needed.

Key Features of a Live Floor Trailer System

Live floor trailer systems incorporate several innovative features that boost their performance and reliability:

Bidirectional Hydraulic Floor Action

The hydraulically powered system moves floor slats in both forward and reverse directions. This dual capability allows operators to control the quantity and placement of materials accurately, reducing waste and the need for additional manual adjustments. Learn more about the mechanics behind this feature in our resource on bidirectional hydraulic floor action.

Quick-Discharge Mechanism

Designed for rapid unloading, live floor systems significantly reduce downtime. Materials such as mulch or soil can be discharged quickly thanks to a well-engineered quick-discharge mechanism, which is especially beneficial in high-volume operations where every moment counts.

Curb-Side Discharge for Targeted Placement

Curb-side discharge enables operators to deliver materials directly where needed, whether it’s filling planting beds or layering mulch along tree lines. This targeted approach minimizes post-unloading adjustments and manual labor. For further details, check out this guide on curb-side discharge.

Handheld Remote Control

A user-friendly handheld remote control allows for precise management of the hydraulic system. Operators can adjust the movement of the slats easily, ensuring that material is transferred in a controlled and safe manner.

High-Capacity and Robust Build

Live floor trailers are built to handle large volumes of materials and are designed for durability. Their robust construction, paired with a high-capacity design, ensures smooth material transport even on rough terrain, making them a versatile choice for various challenging environments.

Advantages of Live Floor Trailer Systems in Bulk-Material Handling

Live floor trailer systems offer compelling benefits that can fundamentally change how you manage bulk materials:

Boosted Productivity

By automating the loading and unloading process, live floor trailers greatly reduce the time and manpower needed for these tasks. Automation has enabled tasks that once required several minutes to be performed much more quickly, allowing businesses to manage more projects each day without compromising on quality.

Enhanced Safety

Traditional dump trailers come with risks such as tipping and the need for strenuous manual adjustments. Live floor systems eliminate many of these dangers by keeping the trailer stable and allowing remote operation. Reduced physical strain also means a lower likelihood of workplace injuries and fewer associated compensation claims.

Increased Profitability

Lower labor costs combined with faster project turnaround times contribute to better profit margins. With fewer crew members required and more efficient operations, businesses see a direct improvement in their bottom line. The reduction in injury risk further enhances savings by lowering insurance and workers’ compensation costs.

Year-Round Versatility

Live floor trailers are designed to be effective across different seasons. In warmer weather, they can efficiently spread mulch and soil, while in cooler months, they can handle leaves, debris, or even heavier materials like stone. Their versatility ensures a strong return on investment regardless of seasonal variations.

If you’re looking for ways to make your landscaping team more efficient and profitable consider a bulk-material handler with a live floor trailer. The Mulch Mule trailer, for example, is a durable, versatile and efficient piece of equipment for landscapers, created by a landscaper. The Mulch Mule features a reversible live floor and can take on all your landscape and hardscape projects with ease.

Check out the video below to see the Mulch Mule live floor in action.

Versatility and Use Cases Across Industries

Live floor trailer systems are not limited to a single application; they are invaluable in a range of industries due to their flexibility and efficiency.

Landscaping and Lawncare

Landscapers can quickly transport and distribute essential materials like mulch, soil, and decorative stones. The precise, controlled discharge minimizes manual handling and accelerates project completion.

Nurseries and Garden Centers

For nurseries, live floor trailers provide a gentle yet effective way to move soils and organic materials, preserving the quality of sensitive products while reducing labor intensity.

Golf Courses and Parks

Maintenance on large green spaces, parks, and fairways becomes more efficient as live floor trailers distribute soil, sand, or organic matter precisely without causing disruption to the turf.

Property Management and Construction

Property managers and contractors benefit from the curb-side discharge and controlled material placement for tasks ranging from filling planter boxes to clearing debris, ensuring consistently neat and efficient project sites.

Handling Diverse Materials

Whether dealing with lightweight mulch or denser aggregates, live floor systems are built to handle significant volumes efficiently, making them an invaluable tool for various types of bulk materials.

How to Get Started with a Live Floor Trailer System

Integrating a live floor trailer into your operations is straightforward when you follow a few key steps:

Evaluate Your Requirements

Begin by assessing the types and volumes of materials you handle regularly. Identify the specific challenges in your current processes that a live floor system could improve, such as excessive manual labor or uneven material distribution.

Analyze Your Budget and ROI

Consider the potential savings in labor costs and increased operational efficiency. A live floor trailer represents a long-term investment by reducing operating expenses and expanding capacity, which can yield significant returns over time.

Experience a Live Demonstration

Request a live demonstration to view the trailer’s capabilities firsthand. Observing the equipment in action can help you understand its benefits and how it might integrate into your existing workflow.

Review Support and Upgrade Options

Ensure that the system meets your current and future needs by reviewing available warranty options, maintenance plans, and upgrade possibilities. Customizable features, such as an automatic tarping system or additional material handling attachments, can be incorporated to further enhance functionality.

Discover How a Live Floor Trailer System Can Boost Profitability for Your Business

Live floor trailer systems redefine bulk-material handling with their innovative, automated approach. By eliminating many of the risks associated with traditional dump trailers and offering precise, efficient material control, these systems improve productivity, enhance safety, and boost profitability. Their adaptability across seasons and industries makes them an indispensable asset for modern businesses.

Ready to revolutionize your material handling process? Contact Mulch Mule today to schedule a live demonstration and discover how their advanced live floor trailer systems can transform your workflow and drive long-term growth.