Landscaping is a demanding industry where speed, precision, and cost-effectiveness can make or break a business. Traditional, manual methods of handling heavy materials—such as mulch, soil, leaves, and stone—not only extend project timelines but also drive up labor costs and increase the risk of worker injuries. In some cases, repetitive lifting can lead to costly workers’ compensation claims.

Many industry reports indicate that material handling solutions can contribute to improved operational efficiency and cost savings. By integrating advanced equipment—such as the Mulch Mule trailer—landscaping operations can reduce manual strain and expedite job completion.

Automating bulk material handling helps reduce the costs normally associated with hiring additional labor. While the specific return on investment varies by project and region, reducing labor hours and minimizing errors can positively impact overall project economics.

Scope of Bulk Material Handling in Landscaping

Today’s landscaping tasks extend well beyond simple lawn care. Professionals frequently manage heavy, bulky materials across a variety of environments—from residential gardens to expansive commercial properties. Historically, many have relied on manual methods such as shoveling or raking, which can lead to uneven material distribution, prolonged work hours, and significant physical strain on employees.

Automation addresses these challenges by minimizing repetitive lifting, improving accuracy, and freeing up teams to focus on more specialized tasks. Technologies that streamline loading, transporting, and distributing materials are useful year-round, which is particularly important as industry research on labor shortages continues to shape human resource strategies. Whether applying mulch in spring, collecting leaves in fall, or hauling stone in winter, automated systems help maintain project schedules by reducing delays associated with manual operations.

Manual Versus Automated: Redefining Time and Cost

Traditional hands-on methods carry hidden costs beyond hourly wages. Extended project timelines raise overhead expenses, while fatigue and injury risks can lead to unexpected losses, including worker’s compensation payouts.

By contrast, automated trailers and handlers reduce the need for manual interventions by streamlining the movement and distribution of materials. Automation helps reduce various bottlenecks by streamlining tasks that were previously managed manually, contributing to a more consistent workflow and supporting on-time project delivery. With less manual labor dependent on each operation, landscaping businesses can complete projects faster, potentially take on more jobs, and improve overall cost efficiency.

Core Automation Technologies in Bulk Material Handling

Advancements in technology have paved the way for numerous innovations that enhance bulk material handling efficiency:

Conveyors and Live Floor Systems

Modern equipment often incorporates powered live floor systems—mechanisms that continuously move materials toward a discharge area. This automation decreases the need for manual shoveling, reducing waste and ensuring more precise material placement.

Curb-Side Discharge and Remote-Control Capabilities

Curb-side discharge mechanisms minimize the need for equipment repositioning by allowing materials to be deposited directly where they are needed, whether along sidewalks or near tree lines. Additionally, remote-control capabilities enhance safety by allowing operators to manage equipment from a safe distance, particularly in confined or congested areas.

Integrated Vacuum Debris Loaders

For seasonal tasks like leaf or storm debris collection, vacuum loaders provide an efficient solution. By suctioning leaves and lighter materials directly into the hopper, these systems help keep job sites cleaner and lower labor demands. Optional debris loader attachments on trailers can eliminate the need for multiple machines, streamlining operations further.

Mulch Mule’s Versatile Features

Among the innovative options is the Mulch Mule trailer, featuring a 15-cubic-yard aluminum hopper and a quick-discharge live floor system. Designed to handle a range of materials—including mulch, soil, and leaves—it offers optional attachments (like leaf vacuum capabilities) that extend its functionality throughout the year. By automating basic tasks, the Mulch Mule contributes to improved workflow efficiency and allows employees more time to focus on specialized, revenue-generating activities.

Watch the video below to learn more about how Mulch Mule provides invaluable features for landscaping businesses.

VIDEO: Mulch Mule General3 – Providing all the features: https://youtu.be/5t50lbUHQ0I?si=ol8qa8sAgH5s6qxi

Benefits of Automating Bulk Material Handling for Landscaping Businesses

Automation offers a broad spectrum of benefits that can fundamentally transform a landscaping business:

- Significant labor cost savings as many repetitive tasks are automated.

- Enhanced employee morale through the reduction of strenuous, repetitive activities.

- Faster project turnaround times, leading to increased client satisfaction and new contract opportunities.

- Improved workplace safety with fewer incidences of back injuries, slips, or repetitive stress issues.

- More precise material distribution that minimizes waste and keeps job sites cleaner.

- Versatility across seasonal tasks, whether handling mulch, debris, or stone year-round.

Overall, automation can enable businesses to manage more projects simultaneously, forge stronger client relationships, and enhance professional credibility.

Real ROI: Dollars and Sense

While advanced material handling equipment may seem like a significant investment initially, the long-term benefits can be substantial. Automation reduces manual labor and the likelihood of costly errors. Many landscaping businesses report operational improvements, such as lower labor hours and enhanced workflow consistency, which contribute to overall savings.

Although precise savings vary depending on factors like regional wage rates and project complexity, the cumulative effect of improved efficiency and reduced manual errors can make a notable impact on profitability.

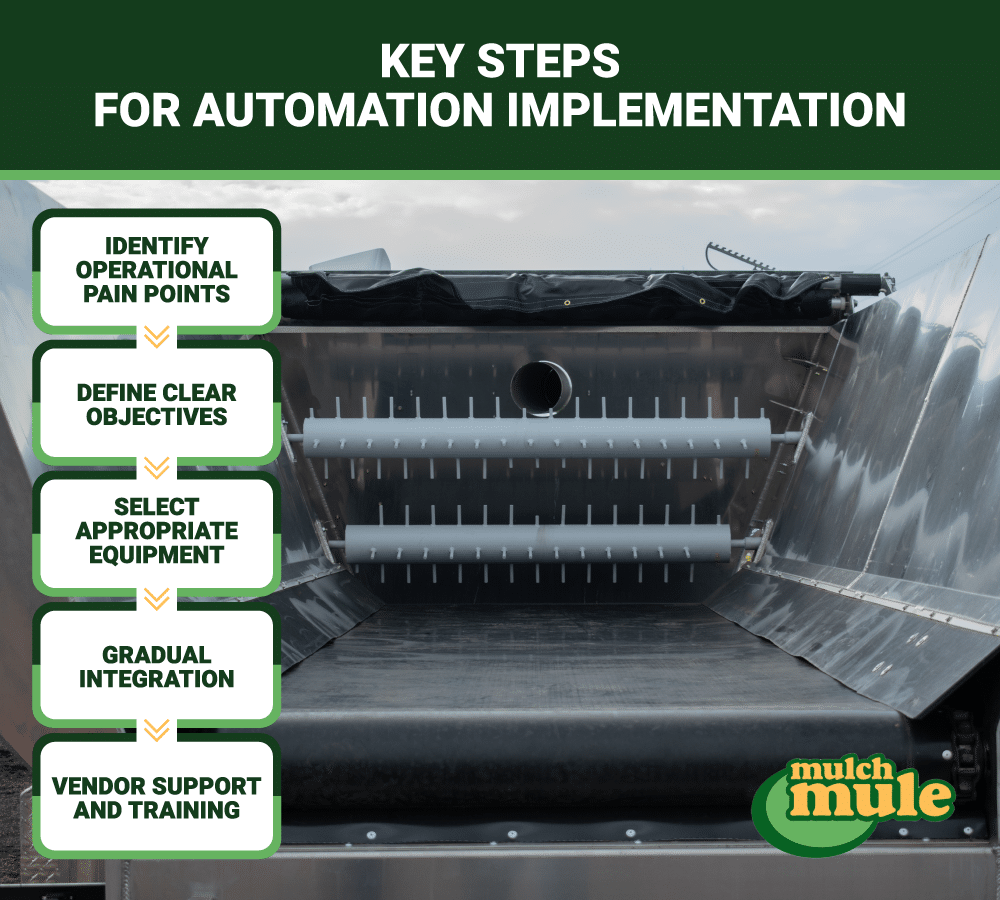

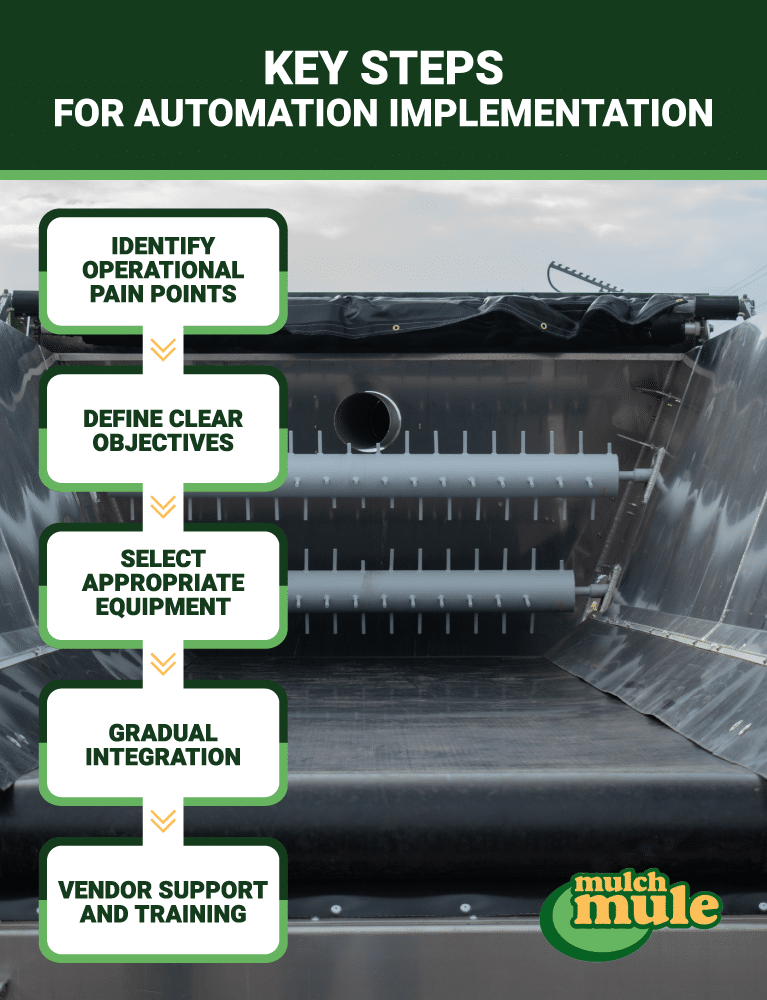

How to Implement Automation in Your Landscaping Business

Introducing automation into a landscaping business does not have to be an overnight overhaul. By evaluating current operations and gradually integrating automated tools, businesses can optimize their workflow and maximize returns:

1. Identify Operational Pain Points

Assess your current processes to determine which repetitive or labor-intensive tasks consume the most time and resources. Identify work that involves heavy lifting or excessive manual handling.

2. Define Clear Objectives

Set measurable goals for automation, such as reducing labor costs by a certain percentage or increasing the number of jobs completed in a season. Clear objectives help guide equipment selection and facilitate performance measurement after implementation.

3. Select the Appropriate Equipment

Match your specific challenges to the right automation tools. For many landscaping operations, a trailer like the Mulch Mule—complete with a live floor system, ample hopper, and optional debris handling features—can serve as an effective solution for enhancing productivity.

4. Plan a Gradual Integration

Implement automation in stages to allow your team to adjust without significant disruption. Begin by automating the most labor-intensive processes and expand as your team grows more comfortable with the new technology.

5. Leverage Vendor Support and Training

Many reputable vendors offer comprehensive product support and training sessions. Make full use of these resources to ensure the correct operation, longevity, and safety of your equipment.

Overcoming Common Pitfalls in Automation Adoption

While automation can deliver significant benefits, it’s essential to address potential challenges proactively:

Managing Upfront Costs

While equipment costs might initially seem high, the long-term savings in labor and the reduction in injury claims can offset these expenses. Many businesses explore financing or lease-to-own options to ease the initial cash-flow burden.

Addressing Employee Concerns

Employees may worry that automation might lead to job cuts. Emphasize that the goal is to relieve them of the most physically demanding tasks, not to eliminate positions. Experience with automation often reveals that employees appreciate reduced strain and are more willing to adapt to enhanced roles.

Ensuring Consistent Maintenance

Even the most advanced equipment requires regular maintenance. Following vendor-recommended service schedules and training staff to identify potential issues can help ensure consistent operation and prevent prolonged downtime.

Measuring Long-Term ROI and Operational Impact

The return on investment from automation evolves over time. Systematically track changes in labor hours, error rates, and project turnaround times to identify additional opportunities for improvement. Continuous feedback from employees further refines workflows, leading to enhanced productivity and greater client satisfaction.

Future Trends and Innovations in Bulk Material Handling

Looking ahead, smarter automation features are poised to redefine how landscaping operations function. Emerging technologies, including sensor-driven material flow adjustments and integrated project management software, will help firms maintain a competitive edge through increased reliability, augmented safety, and more precise job execution.

Sustainability and Environmental Benefits of Automation

More accurate material distribution achieved through automation can contribute to less waste and lower emissions. Many modern automated systems are also designed with fuel efficiency in mind, thereby reducing the carbon footprint compared to older, manual methods. For eco-conscious customers, these sustainability benefits can be a compelling part of your service offering.

Continuous Learning and Workforce Adaptation

As technology evolves, so should your workforce. Continuous training—whether in-house or through vendor-led programs—keeps your team current on the latest operational procedures and safe handling practices. An adaptable, well-trained crew ensures consistent service quality and upholds your reputation for excellence.

Maximizing Client Trust with Data-Driven Insights

Automated systems not only streamline work but also generate robust data that can be shared with clients. By offering precise timelines and measurable efficiency metrics, you build transparency and trust. Clients are more likely to be confident in your services when you can substantiate your operational claims with solid data.

Embrace Automation in Bulk Material Handling Today

Adopting automation in bulk material handling is a strategic decision that can elevate both efficiency and profitability in your landscaping business. With reductions in manual labor, enhanced safety, and faster job turnaround times, solutions like the Mulch Mule trailer offer a pathway to improved operational performance.

For personalized insights or a live demonstration, contact Mulch Mule today. Explore opportunities through the Mulch Mule ambassador program to see firsthand how automation can transform your workflow. Embrace automation to reduce labor costs, boost efficiency, and secure a competitive edge in the landscaping industry.